Minitype LED array chip

A LED array and chip technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems such as the difficulty of making the size of the light-emitting unit small, the inability to meet the needs, and the limitation of resolution, so as to achieve the effect of light-emitting display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

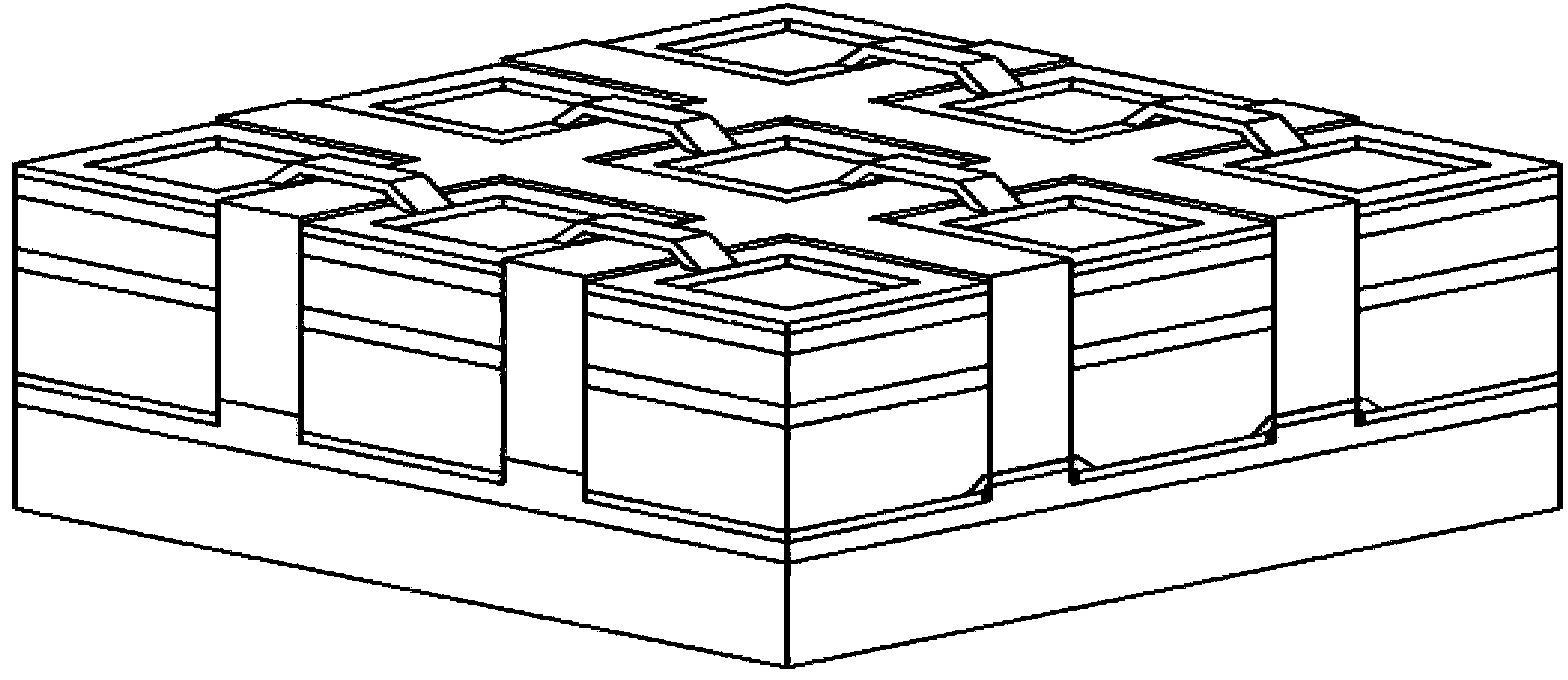

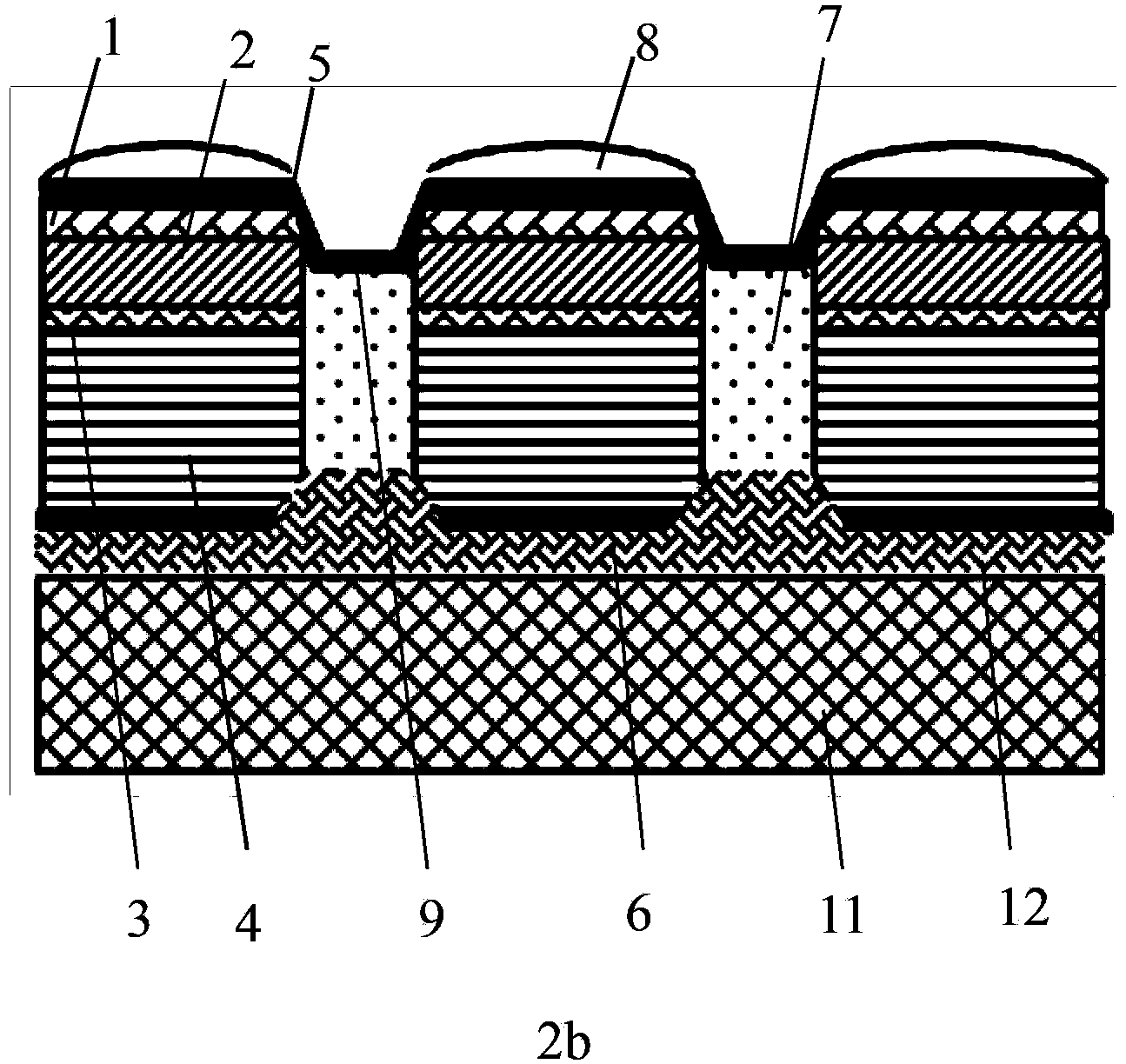

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 8 Describe this embodiment mode, a micro-LED array chip, including a light-transmitting layer 1, a light-emitting layer 2, a reflective layer 3, a substrate 4, an upper electrode 5, an upper electrode lead 9, a lower electrode 6, a lower electrode lead 10, and a diaphragm 7. Microlens 8 and substrate 11;

[0016] The light-transmitting layer 1, light-emitting layer 2, reflective layer 3, substrate 4 and micro-lens 8 form a square or rectangular or circular or other shaped LED light emitting unit. The upper surface of the reflective layer 3 is the luminous layer 2 , the light-transmissive layer 1 and the microlens 8 in sequence, and the lower surface of the reflective layer 3 is the substrate 4 . The LED light-emitting units are uniformly arranged to form a light-emitting unit array. Between the light-emitting units is an aperture 7, which connects each light-emitting unit in sequence and realizes the isol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com