Universal flexible lamination tool for laminated busbar fabrication

A flexible press-fit and laminated busbar technology, which is applied in the direction of insulating conductors/cables, can solve the problems of increasing the R&D trial production cost and trial production time of busbars, and achieves good heat transfer function, shortened processing cycle, and simple maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

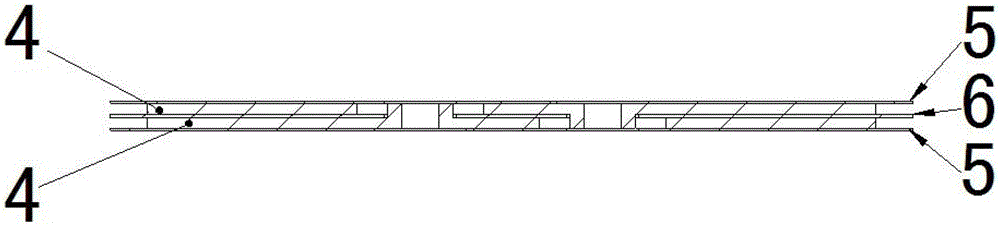

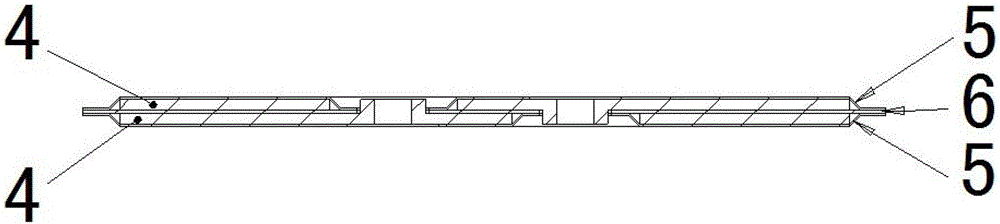

[0023] This embodiment describes a general flexible lamination mold for making laminated busbars. The laminated busbar 1 in this embodiment consists of an outer insulating film 5 , an intermediate insulating film 6 and a copper plate 4 . The structure of the laminated busbar 1 when it is not pressed and closed is as follows figure 2 As shown, the edge is not closed; the edge of the laminated busbar 1 is closed after pressing and sealing, that is, the outer edge and inner hole edge of the laminated busbar 1 are closed, and its structure is as follows image 3 shown.

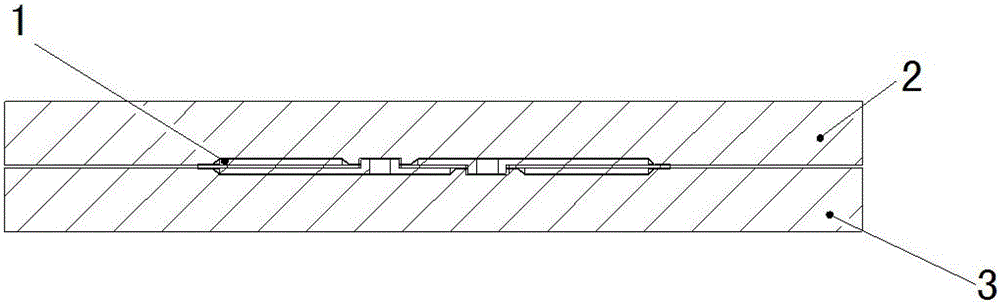

[0024] The universal flexible press die such as Figure 4 As shown, it includes two parts, the upper mold 2 and the lower mold 3. The busbar 1 to be pressed is placed between the upper mold 2 and the lower mold 3. The upper mold 2 includes an upper mold cavity 7 and the The silicone grease 8 , the lower mold 3 includes a lower mold cavity 9 and silicone grease 10 filled in the lower mold cavity 9 . Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com