Double helix light beam-based sample axial drift detection and compensation method and device

A drift detection and compensation method technology, applied in optics, optical components, microscopes, etc., can solve the problems of system debugging and complex operation, and achieve the effect of easy construction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

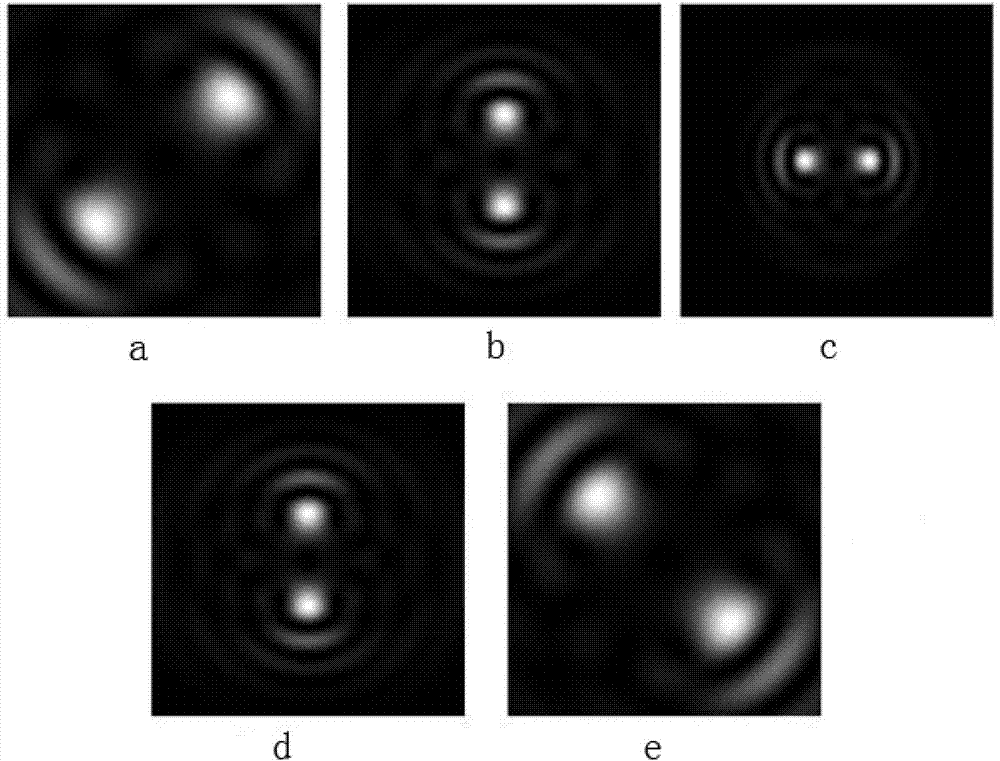

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

[0052] Such as figure 1 As shown, a sample axial drift detection and compensation device based on a double helical beam, including: a laser 1, a single-mode fiber 2, a collimator lens 3, a mirror 4, a spatial light modulator 5, a beam splitting prism 6, a microscope Objective lens 7, three-dimensional nano-scanning platform 8, field lens 9, photoelectric sensing device 10, computer 11.

[0053]Among them, the single-mode optical fiber 2, the collimating lens 3, the reflector 4, the spatial light modulator 5, the beam splitting prism 6, the microscopic objective lens 7 and the three-dimensional nano-scanning platform 8 are sequentially located on the optical axis of the outgoing light path of the laser 1, showing The micro-objective lens 7 focuses the light onto the sample to be measured located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com