Transverse plug LED lamp with high heat dissipation efficiency

A technology of LED horizontal insertion lamp and high heat dissipation, which is applied in lighting and heating equipment, cooling/heating device of lighting device, lighting device, etc. Low problems, to achieve the effect of reasonable heat dissipation structure design, dense fin spacing, and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

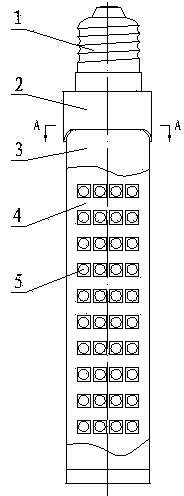

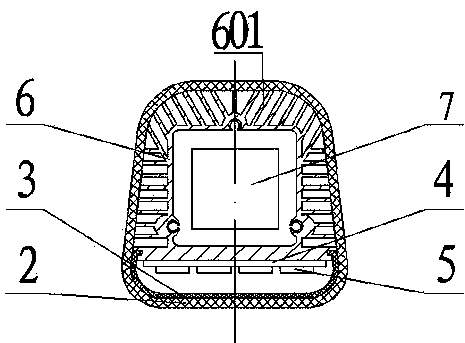

[0010] as attached figure 1 , 2 As shown, the lamp holder 1 and the lamp holder 6 are connected through the connecting piece 2; the lamp holder 1 is a rectangular aluminum alloy tubular body; the printed circuit board 4 is provided with a plurality of LED light sources 5 and pasted on the lamp holder 6 rectangular tubular body On one outer wall of the lamp holder 1, a plurality of cooling fins 601 are arranged on the other three outer walls of the rectangular tubular body; the cooling fins 601 are arranged along the length direction of the tubular body; the thickness of the cooling fins 601 is set to 0.5mm ; The distance between every two adjacent pieces of cooling fins 601 is set to 1mm: the height of cooling fins 601 is set to 3-6mm under the premise of satisfying the shape rules and aesthetics, and the driver 7 is placed in the lamp holder 6 Inside, the lampshade 3 is horizontally inserted into the card slot on the lamp holder 6 and sealed on the outside of the printed cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com