Double-acting compression type packer and use method thereof

A compression packer, double-acting technology, applied in the direction of sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve the problem that the packer’s sealing ability is reduced, the contact stress becomes smaller, and cannot be greatly improved Settling force and other issues to achieve the effect of improving sealing ability and contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For the convenience of description, the double-acting compression packer is called packer in the following part.

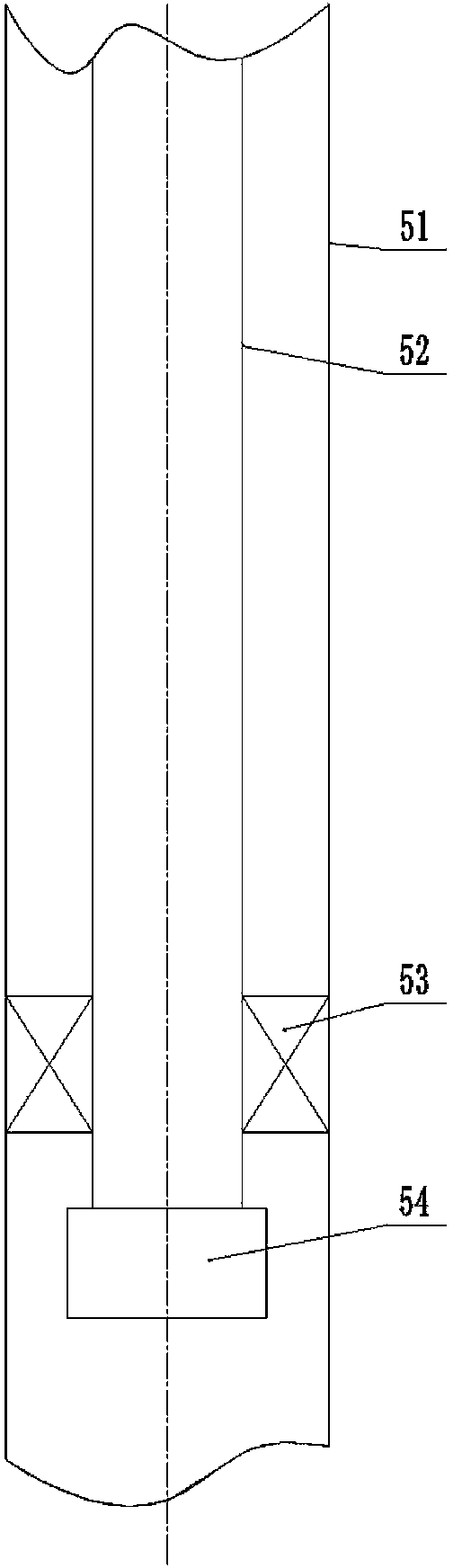

[0024] See figure 1 Shown:

[0025] The upper end of the upper joint 1 is threaded for connecting other tools or strings, and the lower end is connected with the center pipe 2 .

[0026] The upper end of the central pipe 2 is provided with an outer step 32 below the upper joint 1 . The outer tube 3 is sleeved on the outside of the central tube 2 . There is an inner step 31 at the upper end of the outer tube 3, and the inner step 31 corresponds to the outer step 32. When the packer is unpacked, the central tube 2 is lifted up, and the outer step 32 catches the inner step 31.

[0027] The rubber cartridge 4 and the retaining ring 5 jointly constitute a rubber cartridge sealing mechanism. There are many structural forms of the rubber cartridge sealing mechanism, and the common ones are a combination of one rubber cartridge, a combination of two rubber cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com