Low-foaming liquid polyether waste paper deinking agent and synthetic method thereof

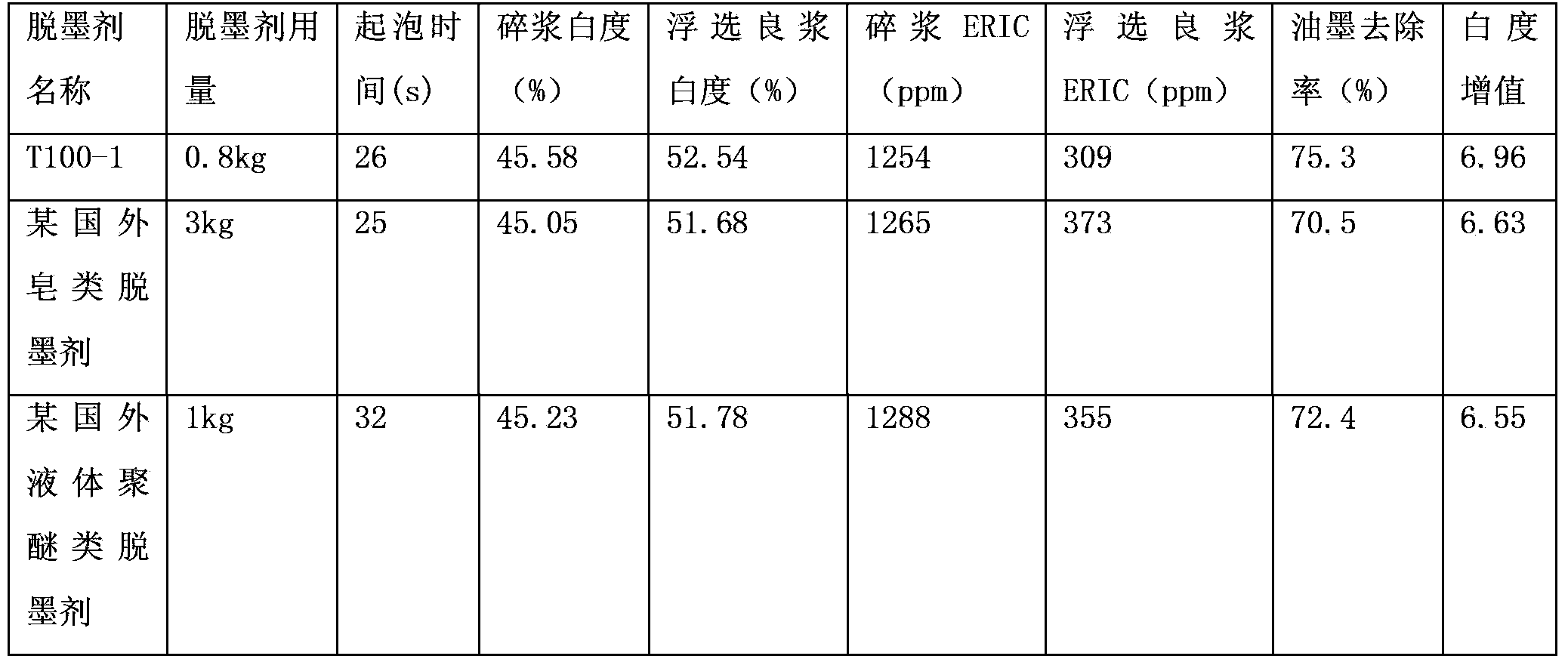

A technology of waste paper deinking and synthesis method, which is applied in processing waste paper, chemical paint/ink remover, paper making, etc. It can solve the problems of affecting the service life of equipment, limited ink collection capacity, harsh use conditions, etc., and achieves Strong ink collection ability, anti-ink redeposition function, whiteness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

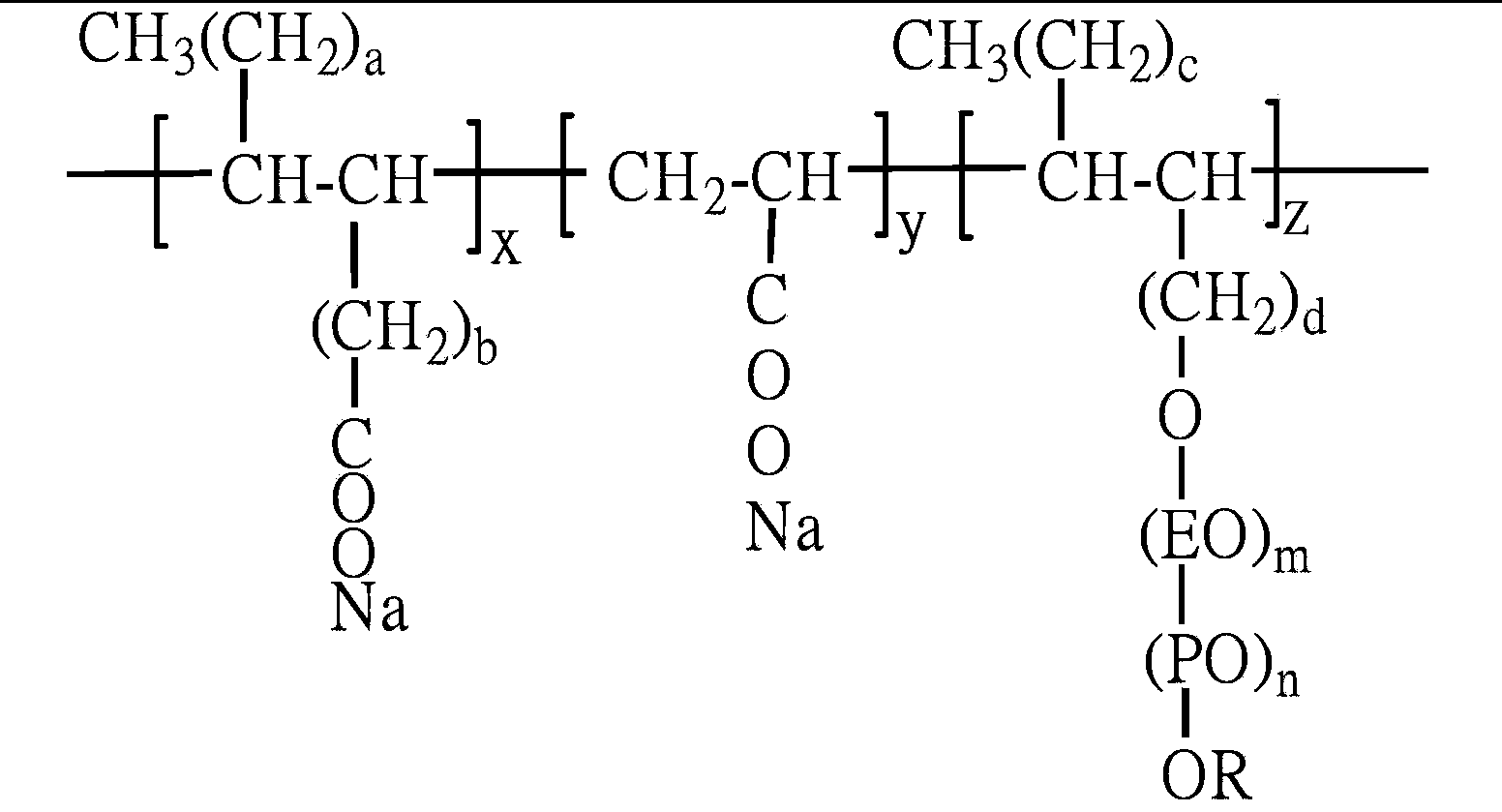

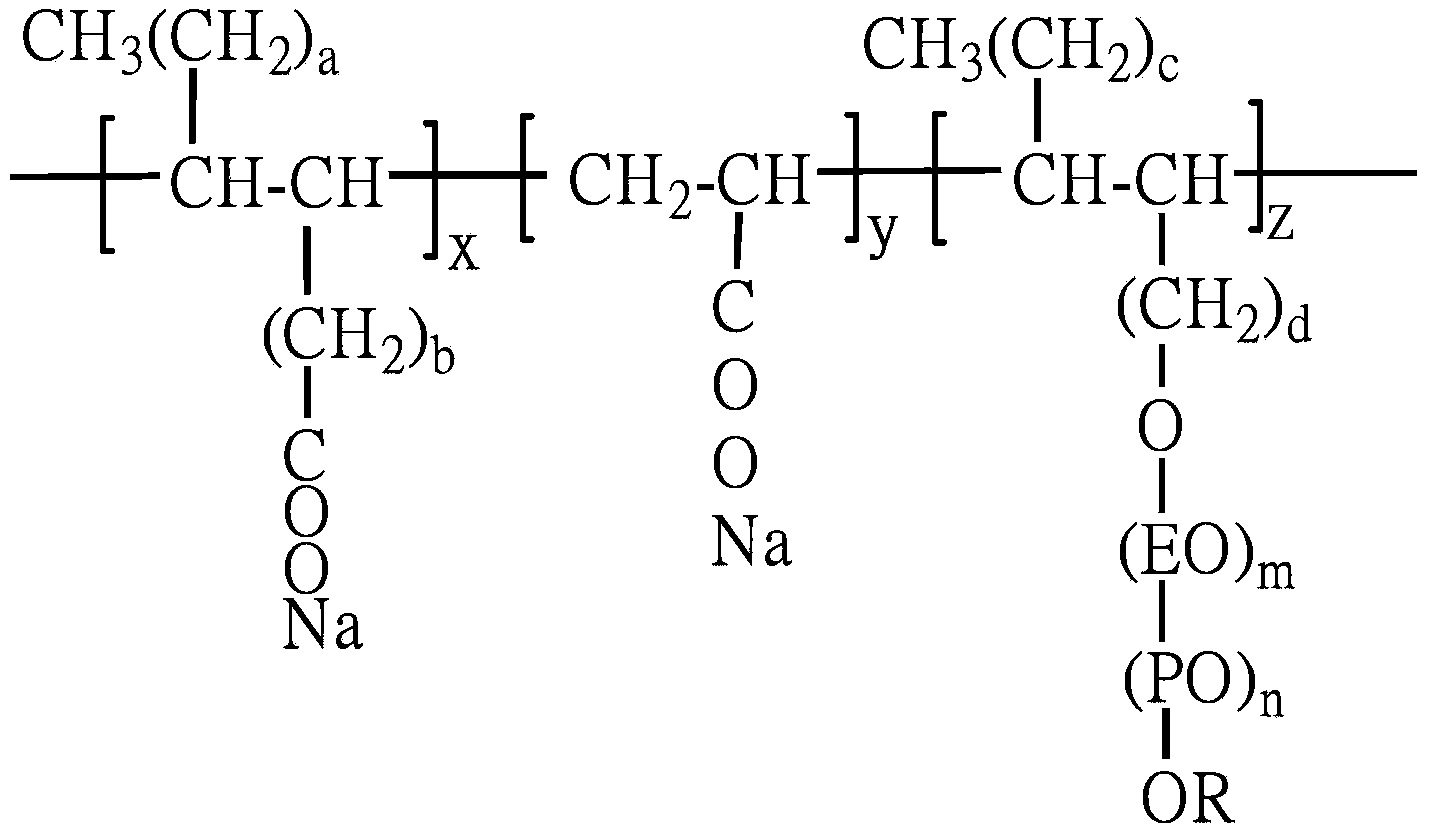

Image

Examples

preparation example Construction

[0025] The present invention further provides a synthetic method of a low-foaming liquid polyether waste paper deinking agent, comprising the following steps:

[0026] (1) Synthesis of enol polyether: add the initiator unsaturated fatty alcohol into the reaction kettle, and at the same time add the catalyst potassium hydroxide, start stirring, raise the temperature to 80-120°C, and remove by vacuum or molecular sieve adsorption and dehydration The weight ratio of moisture to moisture is less than 0.3%, then the temperature is raised to 150-170°C, and ethylene oxide is added. Heat preservation and aging at 165°C for 30-45 minutes to obtain unsaturated enol polyether.

[0027] (2) In the reaction kettle, put the unsaturated long-chain fatty acid, toluene solvent and catalyst formyl peroxide or azobisisobutyronitrile into the reaction kettle, stir and heat to the temperature of 60-80℃, and drop the step (1) For the solution of the prepared product mixed with acrylic acid and tol...

Embodiment 1

[0031] 1. Add 10 mol of prenyl alcohol as starter into the reaction kettle, add 0.53 mol of potassium hydroxide catalyst at the same time, start stirring, heat up to 80-100°C and vacuumize to about 0.1Mpa, remove water until the water weight ratio is less than 0.1 %, then raise the temperature to 150-170°C, slowly add 160mol ethylene oxide in batches (about 10mol per batch, weight about 440g), add 160mol of ethylene oxide after the addition, keep it for 30min, and then add in batches (about 10mol per batch, weight about 440g) About 560g) of 160mol propylene oxide, after the completion of the reaction, heat preservation and aging at 160±5°C for 30 minutes, after cooling down to 80°C, adjust the pH value to 6-7 with phosphoric acid to obtain prenol polyether.

[0032] 2. Put 10mol oleic acid, 30mol toluene and about 100g of the catalyst azobisisobutyronitrile (AIBN) into the reaction kettle first, stir and heat to a temperature of 60°C, and at the same time add 30mol prenol polye...

Embodiment 2

[0035]1. Add the initiator 10mol allyl alcohol into the reaction kettle, and at the same time add 12g potassium hydroxide catalyst (how much?), start stirring, raise the temperature to 100-120°C, and slowly add in batches (about 10mol, about 440g per batch) 300mol ethylene oxide, after adding 140±5°C heat preservation and aging for 25min, then add 80mol propylene oxide in batches (about 10mol in each batch, about 560g), after the reaction is completed, heat preservation and aging at 140±5°C for 45min, then cool down to 85 After ℃, use phosphoric acid to adjust the pH value to 6-7 to obtain allyl alcohol polyether.

[0036] 2. Add allyl alcohol polyether and coconut oil prepared in step 1 into the reaction kettle at a molar ratio of 1:0.8-1.0, add 0.3mol of p-toluenesulfonic acid as a catalyst, and add 15mol of toluene solvent at the same time , stirring and raising the temperature to 130-140° C. for reflux reaction for 2-4 hours. After recovering toluene, the temperature was l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com