Light foamed ceramic wall building material with iron tailings as main raw material

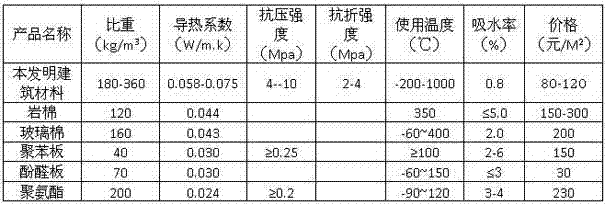

A main raw material, ceramic foam technology, applied in the field of building materials, can solve the problems of easy breeding of bacteria, fire, toxicity, durability, waterproof, and high temperature resistance, and achieve long-term stability of thermal insulation performance, difficult control, and thermal conductivity. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: every portion is 10kg

[0032] A foam ceramic lightweight wall building material with iron tailings as the main raw material, made of the following raw materials in parts by weight: 50 parts of iron tailings, 35 parts of quartz, 5 parts of calcite, 3 parts of soda ash, and 2 parts of borax , 2 parts of alumina, 3 parts of foaming agent.

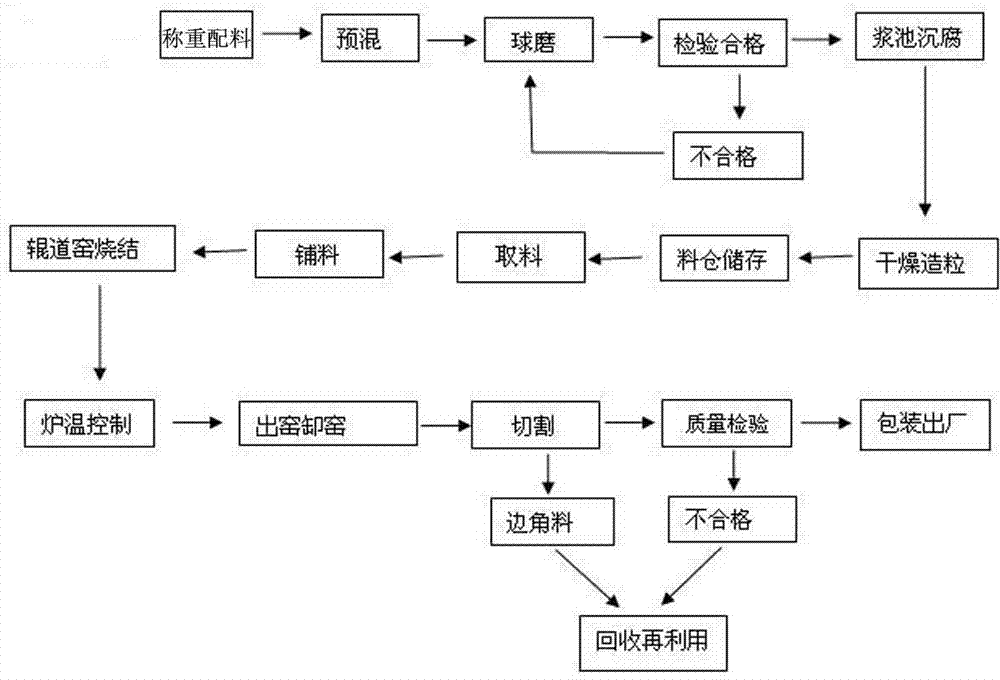

[0033] The production process of the above-mentioned foamed ceramic light-weight wall building material with iron tailings as the main raw material comprises the following steps:

[0034] 1) Weighing ingredients: Weigh each raw material according to its weight part;

[0035] 2) Premixing: fully mix the prepared raw materials;

[0036] 3) Ball milling: Put the fully mixed raw materials into a ball mill for ball milling;

[0037] 4) Fineness inspection: If the raw material is ball-milled to more than 300 mesh, it is qualified and enters the next process, and if it is less than 300 mesh, return to the ball mill to continu...

Embodiment 2

[0048] Embodiment 2: every part is 1kg

[0049] A foam ceramic lightweight wall building material with iron tailings as the main raw material, made of the following raw materials in parts by weight: 48 parts of iron tailings, 33 parts of quartz, 7 parts of calcite, 2 parts of soda ash, and 3 parts of borax , 1 part of alumina, 4 parts of blowing agent.

[0050] The production process of the above-mentioned foamed ceramic light-weight wall building material with iron tailings as the main raw material comprises the following steps:

[0051] 1) Weighing ingredients: Weigh each raw material according to its weight part;

[0052] 2) Premixing: fully mix the prepared raw materials;

[0053] 3) Ball milling: Put the fully mixed raw materials into a ball mill for ball milling;

[0054] 4) Fineness inspection: If the raw material is ball-milled to more than 300 mesh, it is qualified and enters the next process, and if it is less than 300 mesh, return to the ball mill to continue ball ...

Embodiment 3

[0065] Example 3: Each serving is 1 kg

[0066] A foam ceramic lightweight wall building material with iron tailings as the main raw material, made of the following raw materials in parts by weight: 52 parts of iron tailings, 30 parts of quartz, 6 parts of calcite, 1 part of soda ash, and 2 parts of borax , 1 part of alumina, 3 parts of foaming agent.

[0067] The production process of the above-mentioned foamed ceramic light-weight wall building material with iron tailings as the main raw material comprises the following steps:

[0068] 1) Weighing ingredients: Weigh each raw material according to its weight part;

[0069] 2) Premixing: fully mix the prepared raw materials;

[0070] 3) Ball milling: Put the fully mixed raw materials into a ball mill for ball milling;

[0071] 4) Fineness inspection: If the raw material is ball-milled to more than 300 mesh, it is qualified and enters the next process, and if it is less than 300 mesh, return to the ball mill to continue ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com