A kind of production method and formula of environmental protection brick

A production method and technology of environmentally friendly bricks, which are applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of unscientific process, difficulty in obtaining raw materials, and single proportion of ingredients, so as to reduce inventory, Unique effect of environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

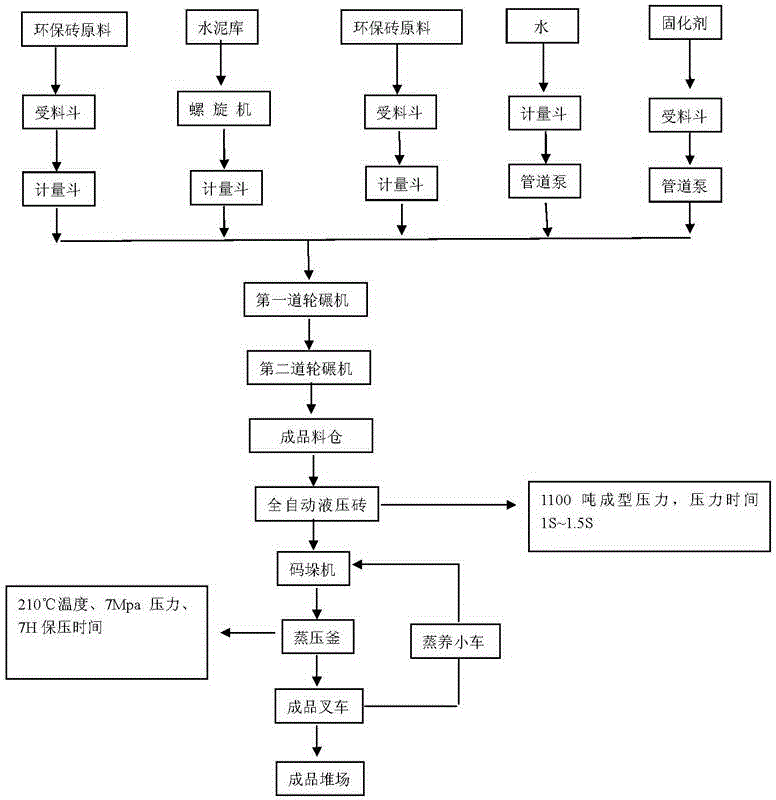

[0021] Such as figure 1 Shown, a kind of production method of environmental protection brick, it comprises the steps:

[0022] The first step is automatic metering and mixing of raw materials.

[0023] Put the raw materials of environmental protection bricks into the receiving hopper in batches, and gradually add the raw materials of environmental protection bricks into the weighing hopper according to the needs from the receiving hopper, and the raw materials of environmental protection bricks measured by the measuring hopper are put into the mixing cylinder.

[0024] Synchronously, the cement in the cement storehouse is transported into the cement metering hopper by the screw machine, and the cement metered by the cement metering hopper is put into the mixing drum.

[0025] Simultaneously, the raw water is pumped into the mixing cylinder by the pipeline pump after passing through the water metering hopper.

[0026] Synchronously, the curing agent is pumped into the mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com