Decolouring method of prepared aqueous nitric acid solution

A nitric acid aqueous solution and nitric acid technology, applied in the direction of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of substandard appearance, large environmental pollution, low production cost, etc., achieve environmental protection and production development, and reduce air pollution , Good safety and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

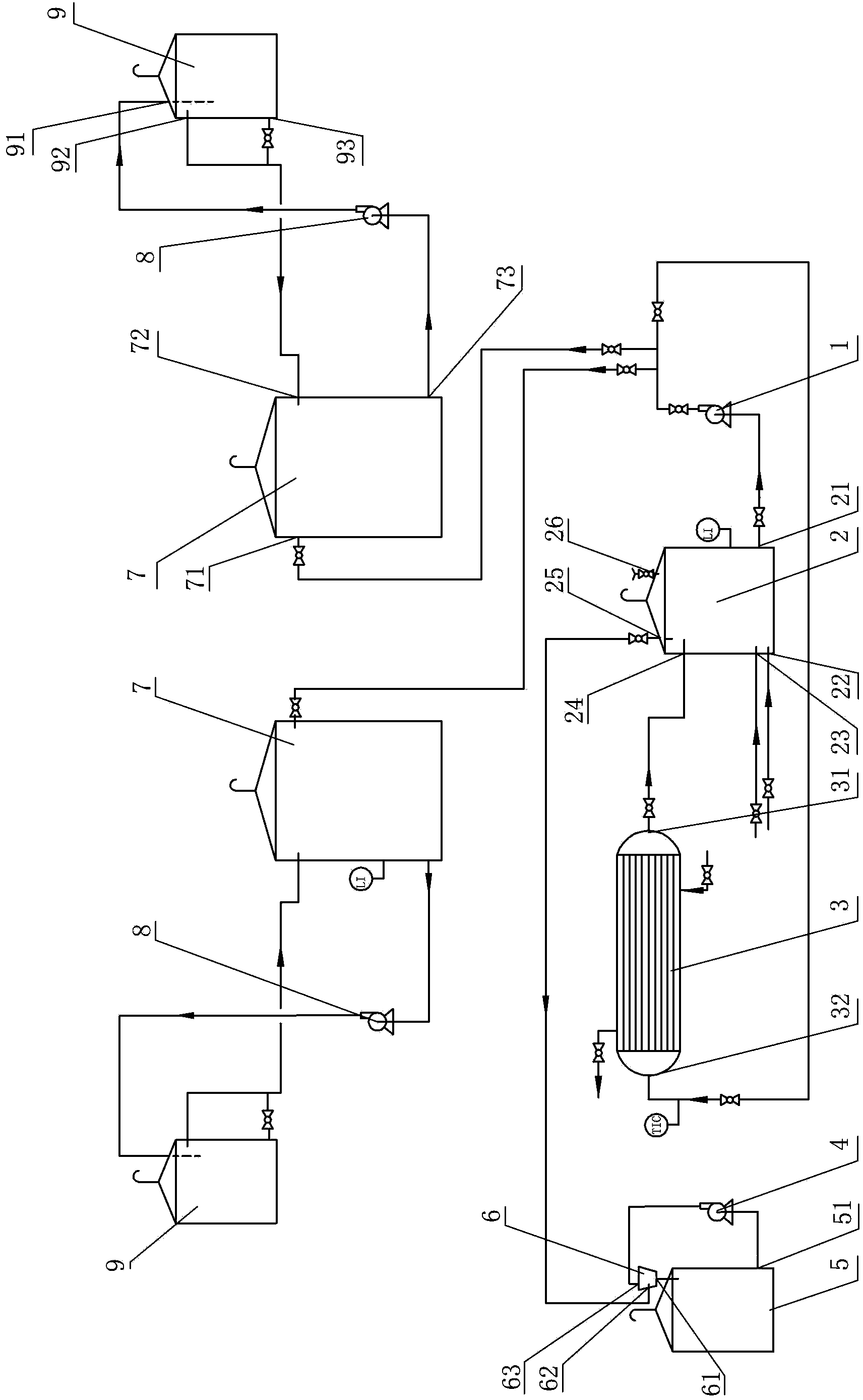

Image

Examples

Embodiment 1- Embodiment 10

[0034] Embodiment 1-embodiment 10: a kind of decolorization method of preparing nitric acid aqueous solution, the device that this method uses is as described above, and its concrete steps are:

[0035] A. Add water into the acid circulation tank 5, then start the negative pump 4 to vacuum the acid circulation tank, the vacuum degree is 0.5-1.0MPa.

[0036] B. Ammonium bicarbonate is first added in the acid mixing tank from the decolorizing agent feeding port 26 of the acid mixing tank 2 in proportion.

[0037] C. Add concentrated nitric acid and dilute nitric acid into the acid distribution tank from the concentrated nitric acid feed port 23 and the dilute nitric acid feed port 22 of the acid distribution tank at the same time in proportion, and the acid mist generated in the process enters the spray from the gas outlet 25 of the acid distribution tank 6, the water in the acid circulation tank is pumped into the injector through the negative pump to mix with the acid mist and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com