Low-temperature activated bleaching agent as well as preparation method and application thereof

A low-temperature activation and bleaching agent technology, applied in the field of bleaching agents, can solve the problems of immature application, etc., and achieve the effect of simple method, low cost, and less fabric damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

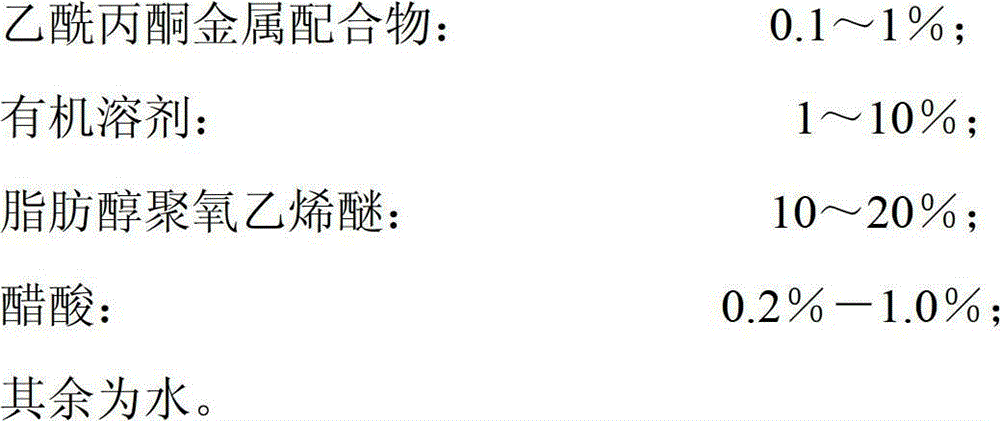

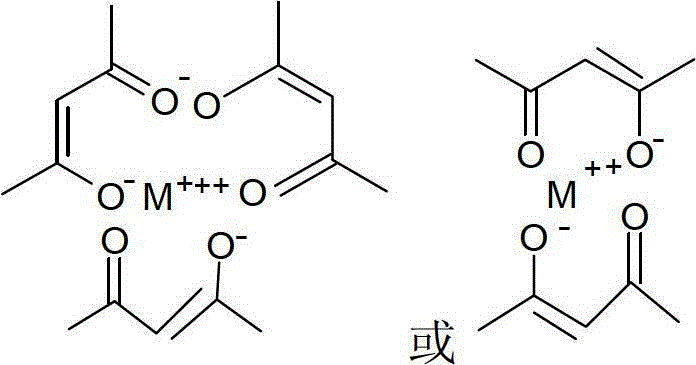

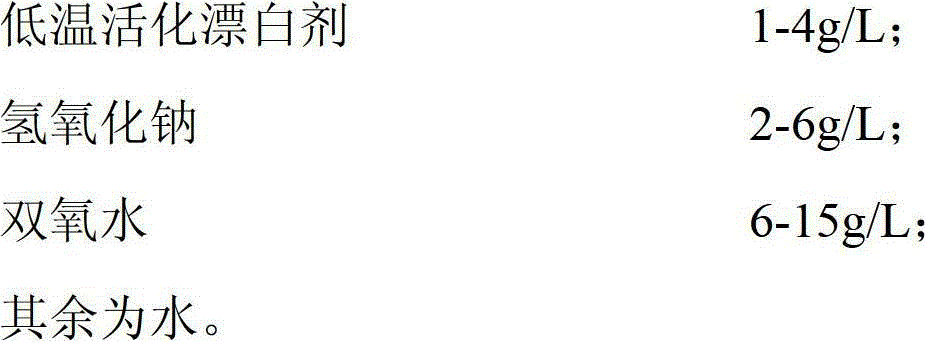

[0025] Mix 20g of isomeric tridecyl fatty alcohol polyoxyethylene ether (8EO), 5g of diethylene glycol butyl ether and 74g of water evenly, then slowly add 1g of manganese (II) metal complex of acetylacetonate, and add acetic acid under mechanical stirring , adjust the pH to 5-6, and then continue to stir at room temperature for 2-3 hours until a transparent liquid is formed, which is a low-temperature activated bleach.

Embodiment 2

[0027] Mix 20g of isomeric tridecanol fatty alcohol polyoxyethylene ether (9EO), 5g of dipropylene glycol monobutyl ether and 74g of water evenly, then slowly add 1g of cobalt(III) acetylacetonate metal complex, and add acetic acid under mechanical stirring, Adjust the pH to 5-6, and then continue to stir at room temperature for 2-3 hours until a transparent liquid is formed, which is a low-temperature activated bleach.

Embodiment 3

[0029] Mix 20g of isomeric tridecanol fatty alcohol polyoxyethylene ether (9EO) with 5g of diethylene glycol and 74g of water, then slowly add 1g of manganese(III) metal complex acetylacetonate, and add acetic acid under mechanical stirring to adjust the pH 5-6, and then continue to stir at room temperature for 2-3 hours until a transparent liquid is generated, which is a low-temperature activated bleach.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com