Laser pattern printing device

A pattern printing and laser technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of long heating time, high-speed operation, high cost, etc., achieve high printing position accuracy, improve work efficiency, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

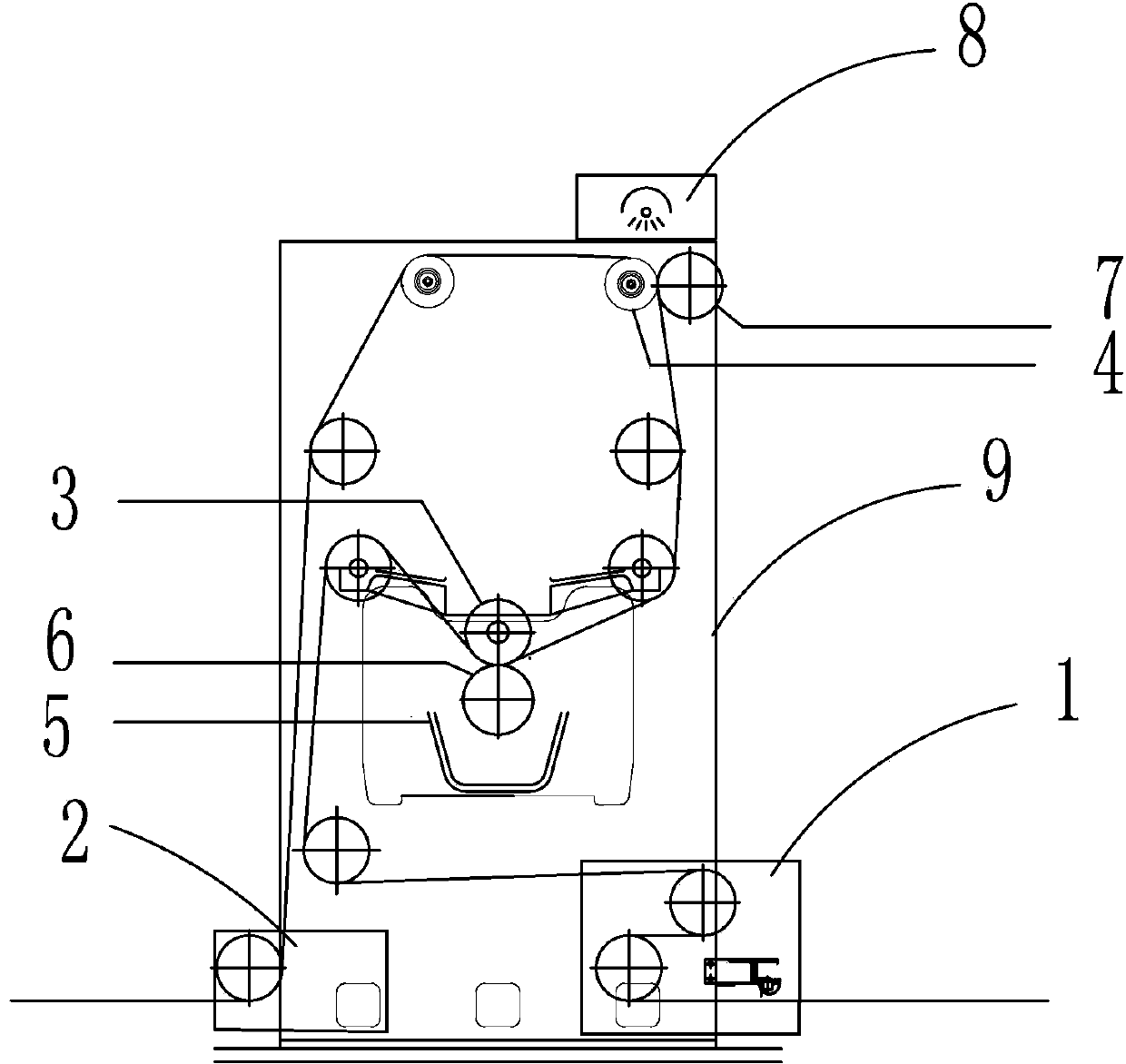

[0019] Such as figure 1 As shown, a laser pattern printing device includes a frame 9, on which a paper feeder 1 and a paper discharge device 2 are arranged, and between the paper feeder 1 and the paper discharge device 2 There is a paper belt transmission device composed of a plurality of transmission wheels and used to drive the paper belt. The two transmission wheels in the paper belt transmission device are respectively a coating transmission wheel 3 and an embossing transmission wheel 4. The coating transmission wheel 3, there is a container 5 for containing UV varnish, and the container 5 is provided with a coating roller 6 that uniformly coats the UV varnish on the paper tape to form a UV varnish layer through its rotation, and the coating roller 6 and The coating drive wheels 3 are closely matched with each other, and the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com