Pneumatic expansion type clamp

A pneumatic expansion clamp technology, which is applied in the field of machining fixtures, can solve the problems of prolonging the processing cycle, long processing auxiliary time, and increasing processing costs, and achieve the goal of increasing the length of the force arm, convenient and quick clamping, and improving processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

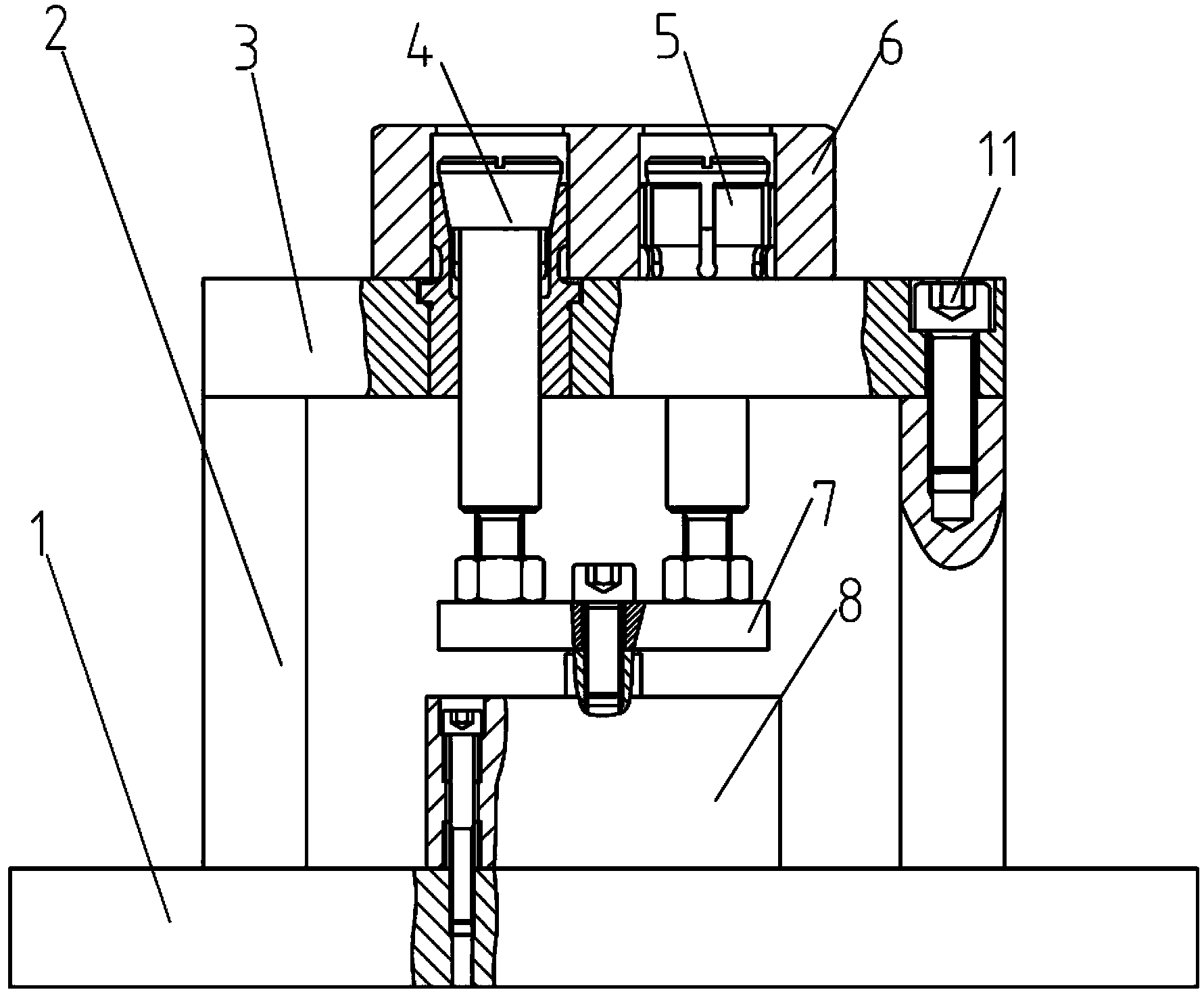

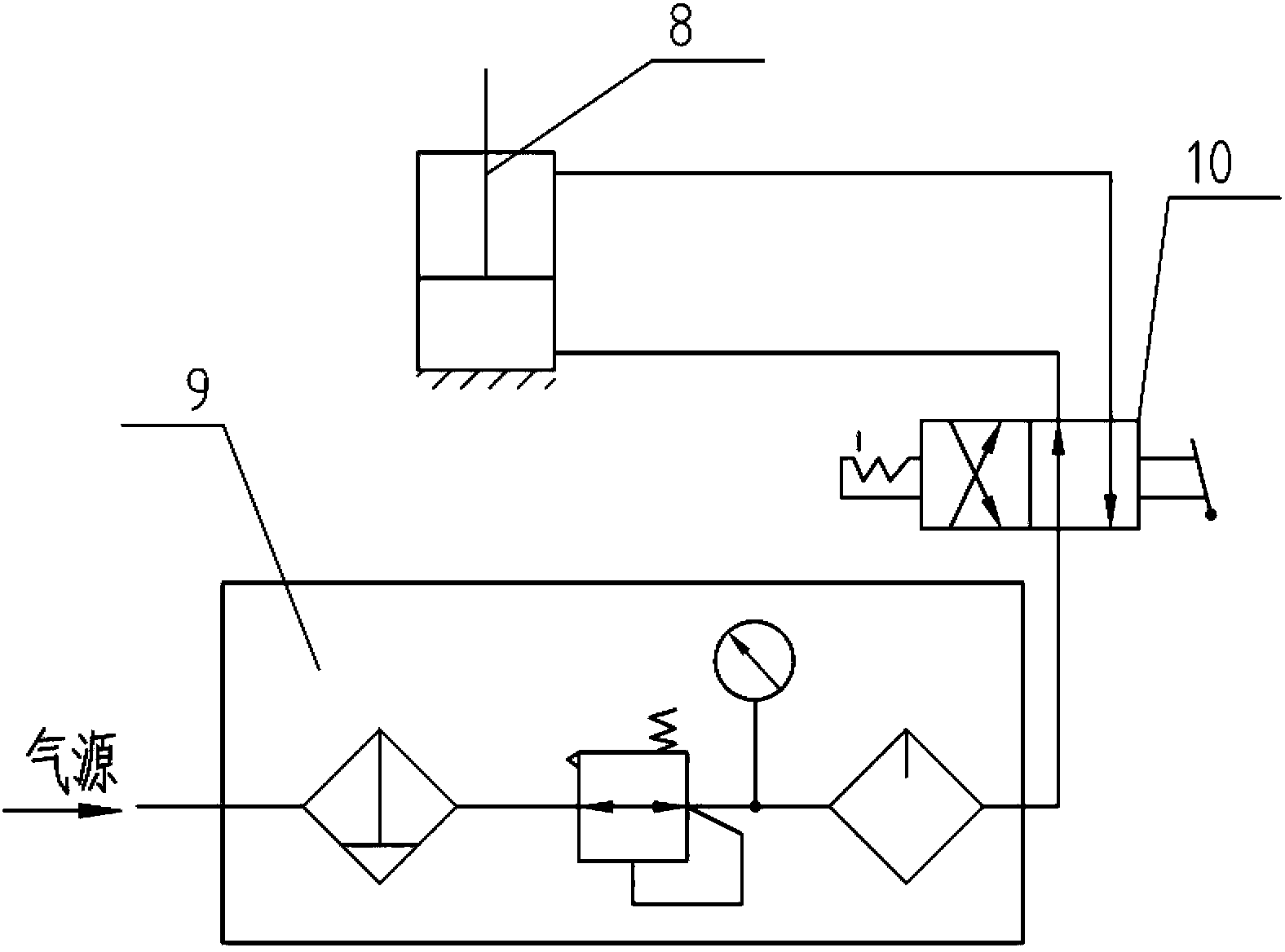

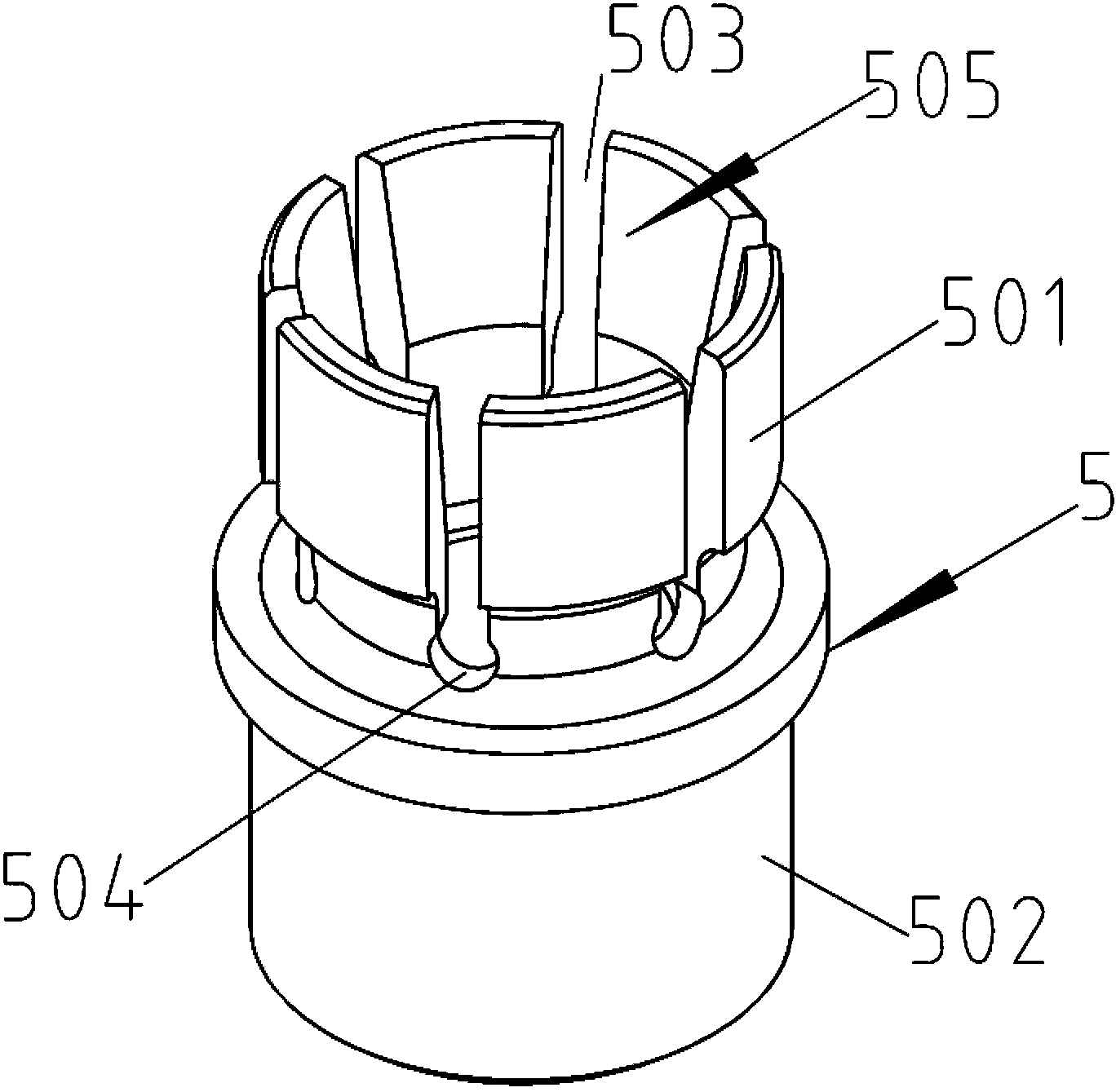

[0021] See attached figure 1 ~ Attached Image 6 The pneumatic expansion clamp includes a bottom plate 1, two support plates 2, a positioning plate 3, a tie rod 4, an expansion sleeve 5, a cross rod 7 and a cylinder 8; the two support plates 2 stand on the bottom plate 1 respectively On both sides of the top surface, the positioning plate 3 is located at the top end of the two supporting plates 2 and is fixedly connected with the two supporting plates 2; the positioning plate 3 is provided with a hole penetrating the positioning plate 3 The pull rod 4 and the expansion sleeve 5; the lower end of the pull rod 4 and the lower end of the expansion sleeve 5 are both fixedly connected to the cross rod 7, and the cross rod 7 is opposite to the piston of the cylinder 8. Fixed connection.

[0022] The top end of the support plate 2 is provided with a screw hole, the positioning plate 3 is provided with a through hole that penetrates the positioning plate 3 along the thickness direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com