Wheat impurity removing winnowing machine

A technology for hoisting and raising wheat is applied in the field of wheat removal and hoisting, which can solve the problems of low efficiency, high labor intensity and dependence on weather, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

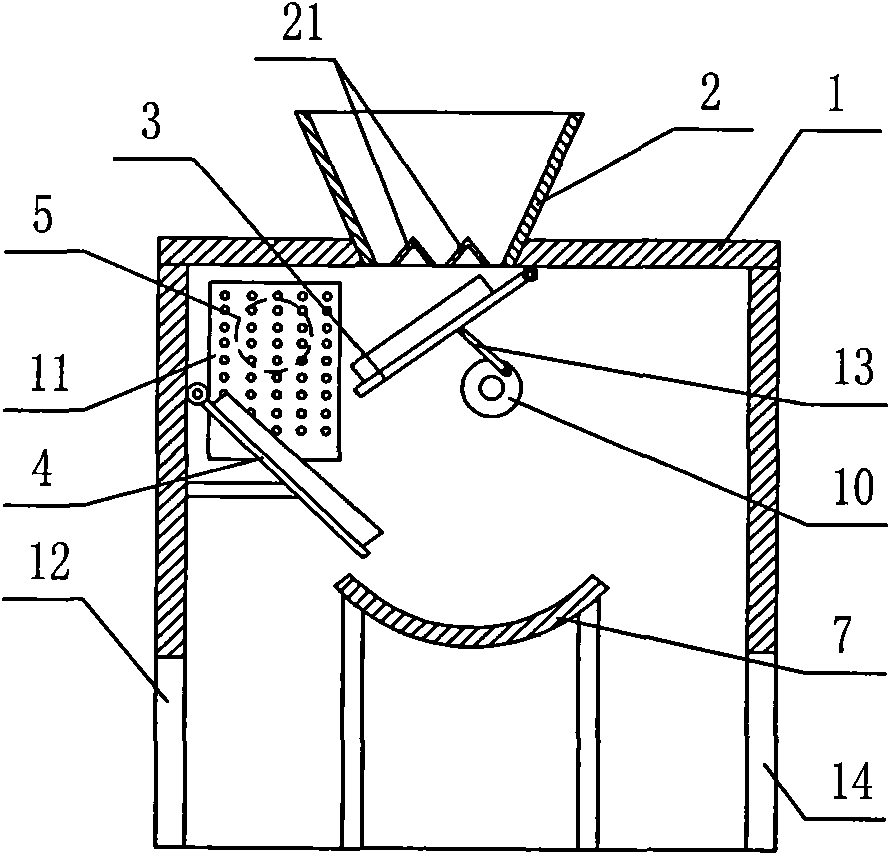

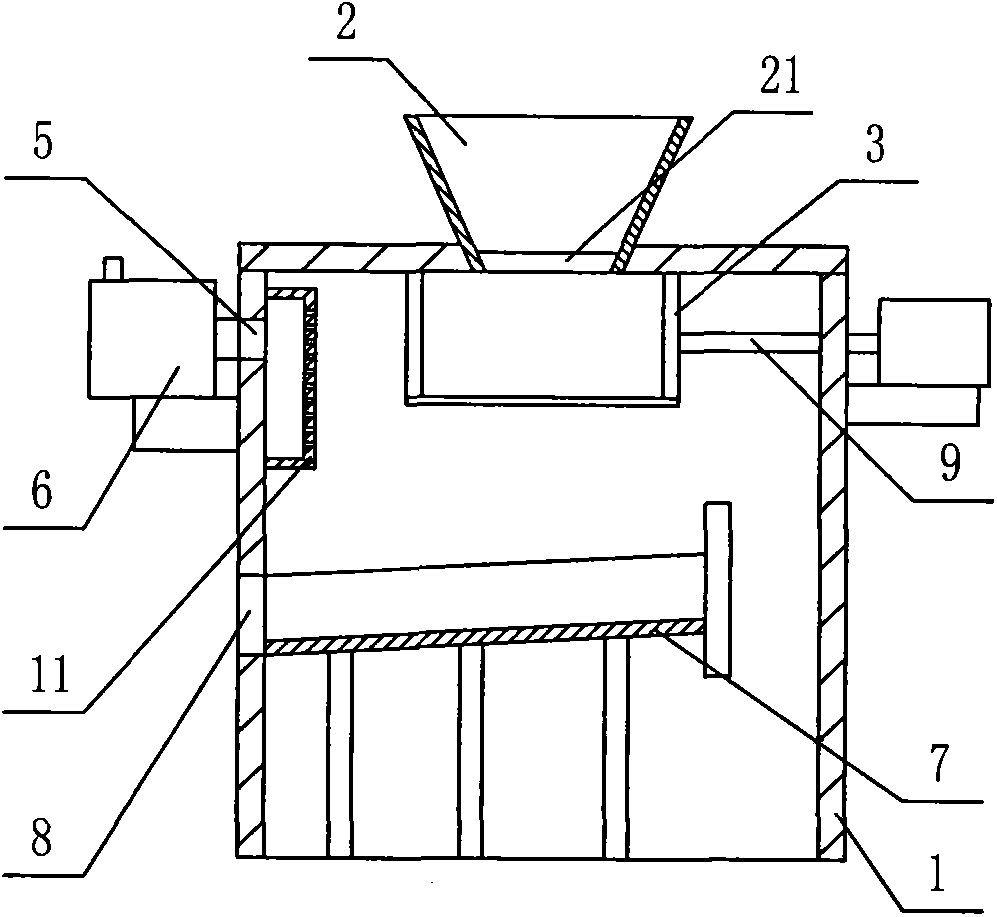

[0015] Such as figure 1 and figure 2 The shown a kind of wheat remover impurity raising machine, it comprises cabinet 1, and the front portion of the top wall of cabinet 1 is provided with feeding funnel 2, and uniform distributor 21 is housed in feeding funnel 2, and the front part of cabinet 1 is hinged with corresponding feeder. The material hopper 2 is equipped with a lifting plate 3 driven by a swing mechanism. The rear end of the lifting plate 3 is hinged on the inner top wall of the dryer box 1 and is inclined downward from the back to the front. The front inner wall of the box 1 is also hinged. There is a deflector inclined plate 4 located at the lower part of the front of the lifting plate 3, and the side wall of the cabinet 1 is provided with an air inlet 5 and an impurity removal fan 6 that blows air into the inner cavity of the cabinet 1 through the air inlet. The material guide sieve plate 7 that is set below the discharge end and is inclined downward to the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com