A vacuum shock absorption plate for a range hood and a range hood bellows using the same

The technology of a range hood and a shock absorber is applied in the direction of removing oil fume, application, household stove, etc. It can solve the problems of complex manufacturing process, small force acting surface, small force surface, etc., and achieves good sound insulation and shock absorption effect. The effect of reducing vibration noise and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

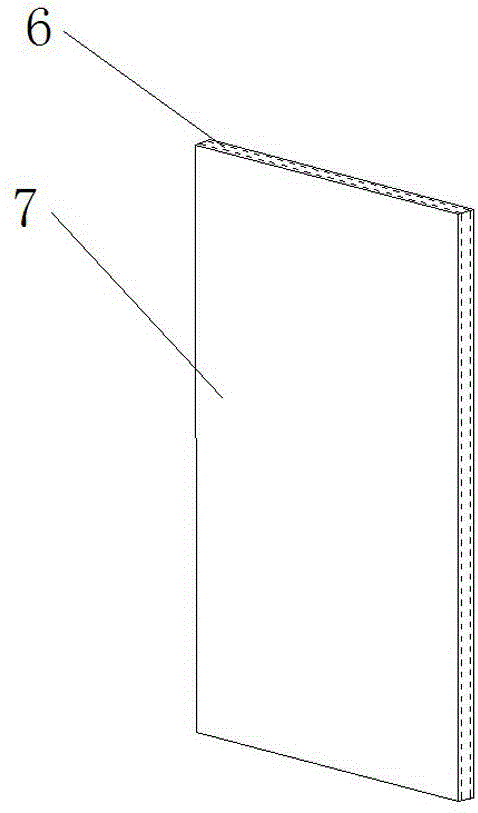

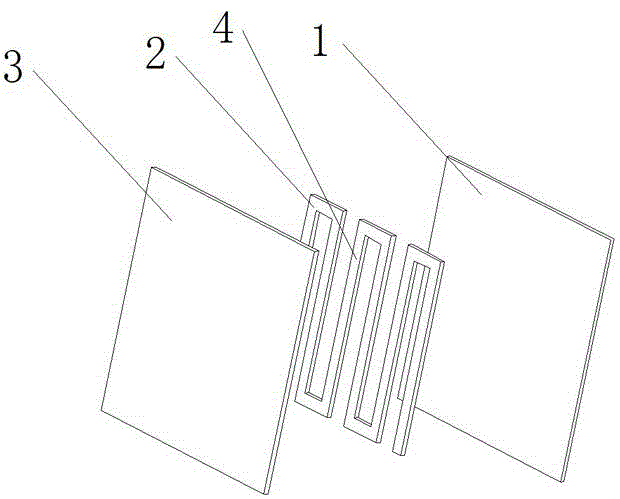

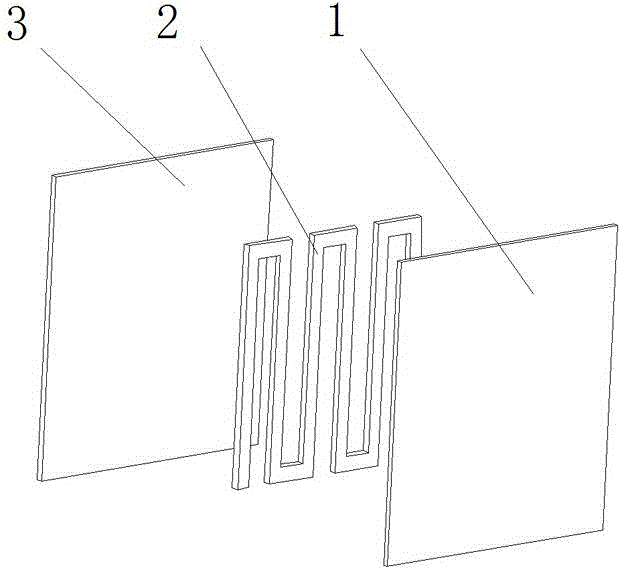

[0023] Embodiment one: see Figure 1-Figure 3 , this product includes an inner panel 1, a support member 2 and an outer panel 3, the inner panel 1 and the outer panel 3 are mutually encapsulated to form a shock-absorbing panel 7 with an interlayer 6, and the interlayer between the inner panel 1 and the outer panel 3 6 is a sealed vacuum chamber, and the air pressure of the interlayer 6 is 10 -1 Pa, the inner panel 1 and the outer panel 3 are supported by the support member 2, the support member 2 is a folded support bar, which is composed of several parallel support straight bars 4 that are folded back and forth in the horizontal direction, and the support straight The quantity of bar 4 can increase or decrease according to the area size of damping plate 7, when the area of damping plate 7 is bigger, the quantity of supporting straight bar 4 can be increased, when the area of damping plate 7 is less, the quantity of supporting straight bar It can be reduced. In addition, ...

Embodiment 2

[0025] Example 2: Participate in Figure 4-6 , this embodiment relates to a range hood bellows 5, using the vacuum damping plate 7 of the range hood in the first embodiment above, the outer plate 3 of the damping plate 7 faces the outside of the bellows, and the inner plate 1 of the damping plate 7 towards the inside of the bellows.

[0026] Since the vacuum damping plate 7 is used as the plate material, the noise of the internal fan can be minimized during the use of the range hood, and the strength of the outer shell of the bellows can be ensured at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com