Recovery method using membranes for terephthalic acid and sodium hydroxide from printing and dyeing alkali-reduced waste water

A terephthalic acid and alkali reduction wastewater technology, applied in the direction of alkali metal oxides/hydroxides, chemical instruments and methods, separation/purification of carboxylic acid compounds, etc., can solve the problem of large consumption of inorganic acids and poor purity High, precipitation and separation difficulties and other problems, to achieve the effect of solving the discharge of wastewater up to standard, reducing production costs, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

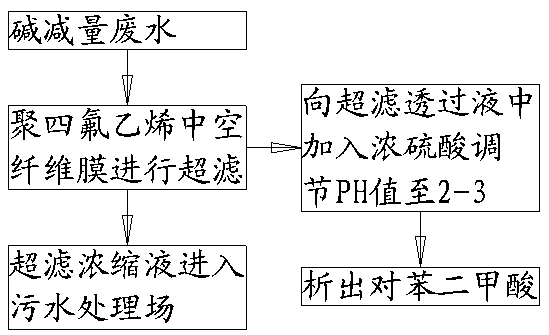

[0025] Such as figure 1 Shown: a method for recycling terephthalic acid and sodium hydroxide by printing and dyeing alkali weight reduction wastewater membrane, comprising the following steps:

[0026] (1) Collect printing and dyeing alkali reduction wastewater, use polytetrafluoroethylene hollow fiber membrane for ultrafiltration, obtain ultrafiltration concentrate and ultrafiltration permeate after ultrafiltration, and the ultrafiltration pressure is 0.3MPa,

[0027] (2) Enter the ultrafiltration concentrate into the sewage treatment plant,

[0028] (3) Add concentrated sulfuric acid to the ultrafiltration permeate to adjust the pH value to 2, and precipitate terephthalic acid,

[0029] In addition, the particle size in the ultrafiltration permeate obtained in the step (1) is below 0.2 μm, and the volume of the ultrafiltration permeate accounts for 90% of the treatment capacity of the printing and dyeing alkali reduction wastewater. The liquid volume accounts for 10% of th...

Embodiment 2

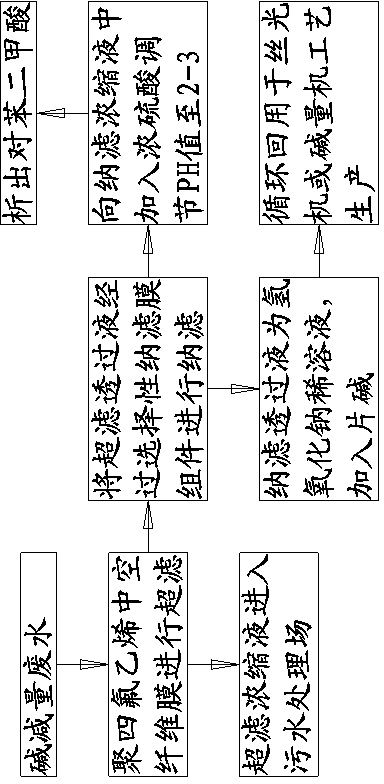

[0033] Such as figure 2 Shown: a method for recycling terephthalic acid and sodium hydroxide by printing and dyeing alkali weight reduction wastewater membrane, comprising the following steps:

[0034] (1) Collect printing and dyeing alkali reduction waste water, use polytetrafluoroethylene hollow fiber membrane for ultrafiltration, obtain ultrafiltration concentrate and ultrafiltration permeate after ultrafiltration, and the ultrafiltration pressure is 0.1MPa,

[0035] (2) Enter the ultrafiltration concentrate into the sewage treatment plant,

[0036] (3) The ultrafiltration permeate is subjected to nanofiltration through the selective nanofiltration membrane module, and the nanofiltration concentrate and nanofiltration permeate are obtained after nanofiltration. The nanofiltration pressure is 0.2MPa,

[0037] (4) Add concentrated sulfuric acid to the concentrated nanofiltration solution to adjust the pH value to 2, precipitate terephthalic acid, and recycle the mother liquor...

Embodiment 3

[0045] Another example figure 2 Shown: a method for recycling terephthalic acid and sodium hydroxide by printing and dyeing alkali weight reduction wastewater membrane, comprising the following steps:

[0046] (1) Collect printing and dyeing alkali reduction waste water, use polytetrafluoroethylene hollow fiber membrane for ultrafiltration, obtain ultrafiltration concentrate and ultrafiltration permeate after ultrafiltration, and the ultrafiltration pressure is 0.3MPa,

[0047] (2) Enter the ultrafiltration concentrate into the sewage treatment plant,

[0048] (3) The ultrafiltration permeate is subjected to nanofiltration through a selective nanofiltration membrane module, and the nanofiltration concentrate and nanofiltration permeate are obtained after nanofiltration. The nanofiltration pressure is 0.5MPa,

[0049] (4) Add concentrated sulfuric acid to the concentrated nanofiltration solution to adjust the pH value to 3, precipitate terephthalic acid, and recover and recyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com