Method for feeding refined tea material into sterile packing room

A material and material box technology, applied in the field of safe production of tea beverages, can solve the problem of high cost of disinfection and sterilization, and achieve the effects of improving the efficiency of sterilization work, the effect is remarkable, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention can be implemented on a tea production line.

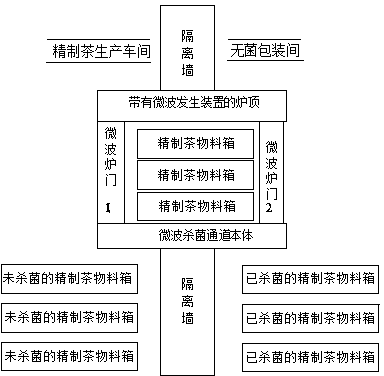

[0018] A wall hole is opened in the partition wall between the refined tea processing workshop and the aseptic packaging room of the tea production line, and the microwave sterilization channel is built in the wall hole.

[0019] The microwave sterilization passage is composed of a microwave sterilization passage body, a stove top with a microwave generating device, a microwave oven door 1 facing the refined tea production workshop and a microwave oven door 2 facing the aseptic packaging room.

[0020] When the refined tea is sent to the aseptic packaging room, the operator of the refined tea production workshop first packs the refined tea processed in the production workshop into the refined tea material box, and opens the microwave oven door 1 of the microwave sterilization channel (at this time, the microwave The microwave oven door 2 of the sterilization channel is closed), put the material box containing refined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com