Automatic multifunctional continuous processing online equipment for metal circular tube bar

A round tube rod, multi-functional technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of unable to automatically complete the connection, waste of manpower, costly operation, maintenance equipment, etc., to achieve compact structure and improve production efficiency , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

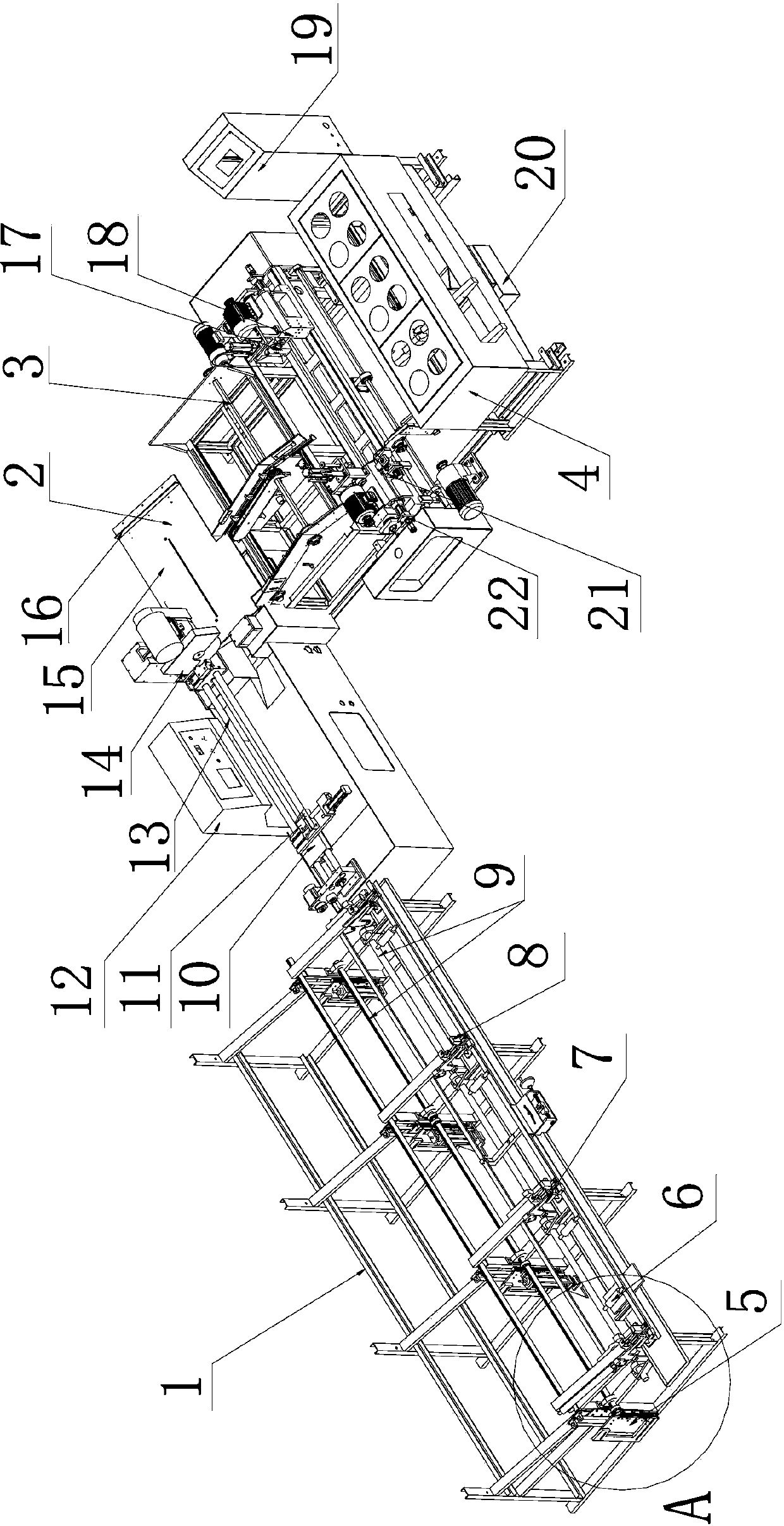

[0017] Such as Figure 1-2 As shown, the automatic multi-functional continuous processing and connection equipment for metal round pipe rods described in the embodiment of the present invention includes an automatic material preparation mechanism 1, a sawing mechanism 2, an automatic chamfering machine detection mechanism 3, an automatic cleaning mechanism 4 and pipe fittings Conveying mechanism, the tail of the automatic material preparation mechanism 1 is connected to the sawing mechanism 2, the automatic chamfering machine detection mechanism 3 is connected to the rear side of the sawing mechanism 2, and the automatic cleaning mechanism 4 is connected to the automatic chamfering machine detection mechanism The rear side of the mechanism 3, the pipe delivery mechanism is connected to the rear side of the automatic cleaning mechanism 4.

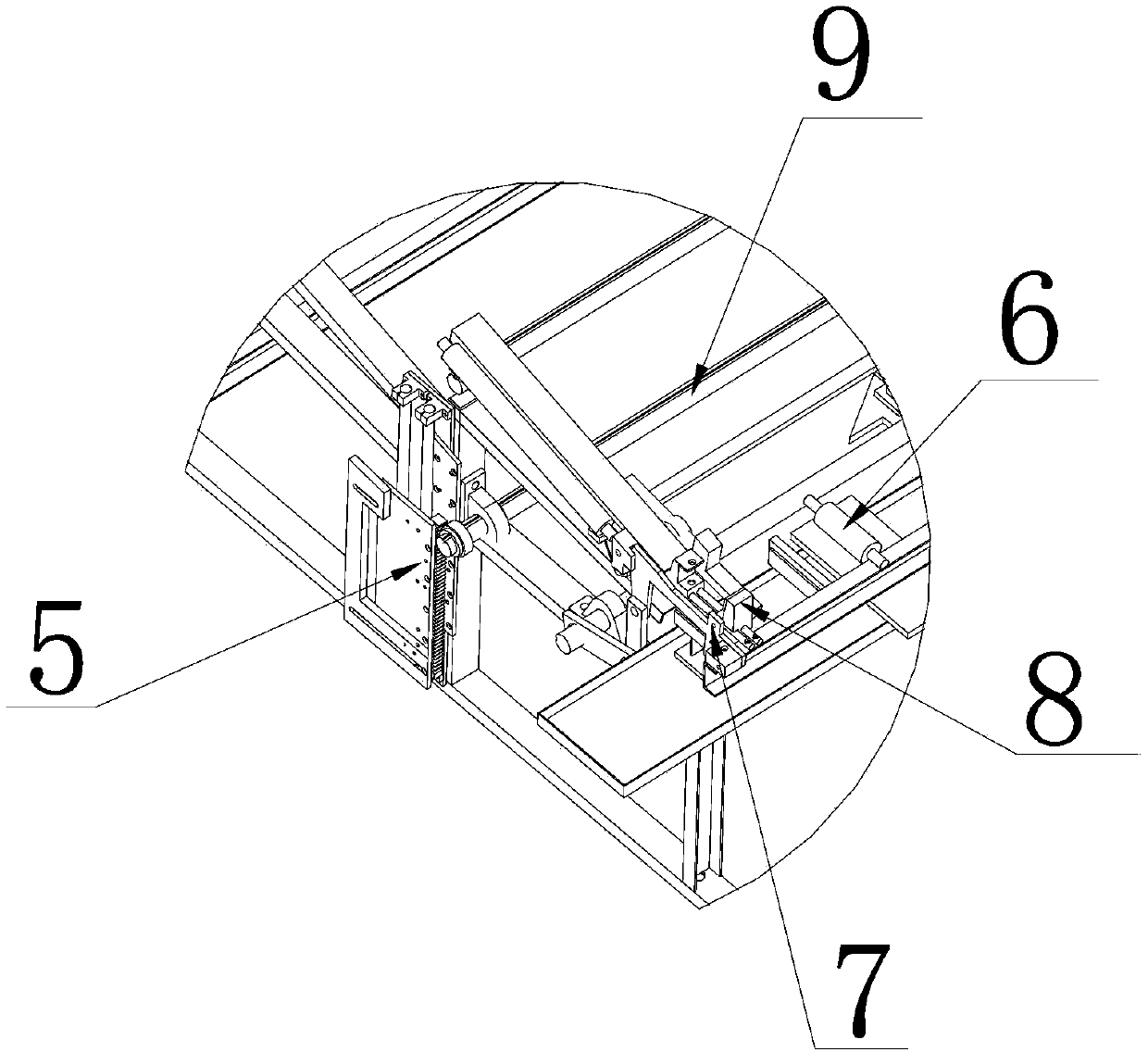

[0018] The automatic material preparation mechanism 1 is provided with a drive shaft 9, and the front portion of the automatic material pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com