Mold electric-switch intelligent biomass forming machine

A biomass molding machine, electric switching technology, applied in the direction of mold extrusion granulation, etc., to prevent abnormal work, improve adaptability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

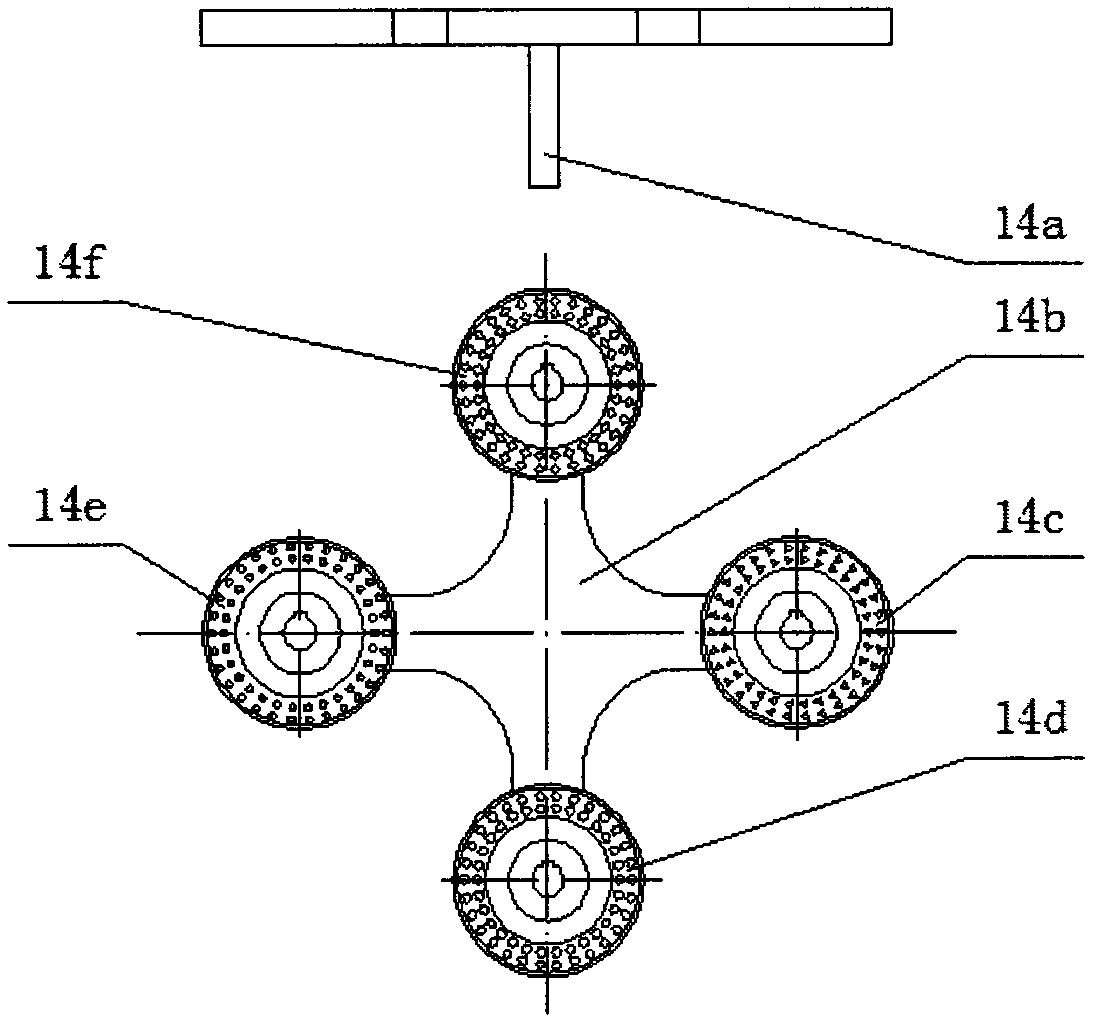

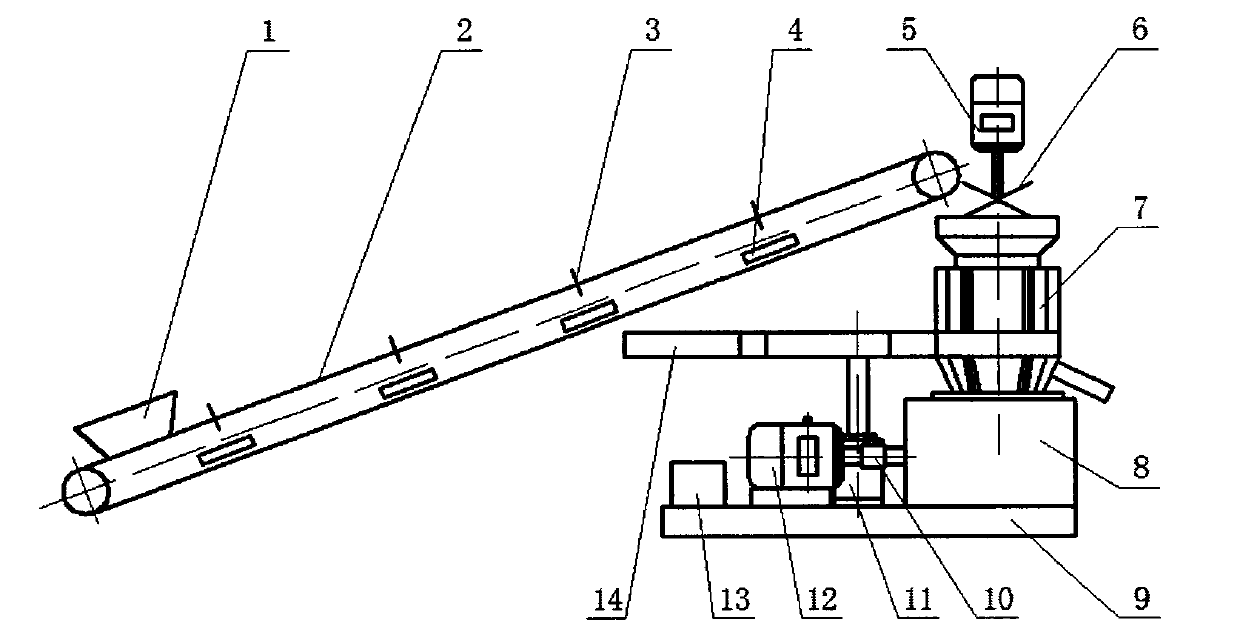

[0015] A biomass molding machine with automatic mold switching, including a feeding hopper 1, a feeding belt 2, a humidity sensor 3, a heating wire 4, a stirring motor 5, a stirring blade 6, a granulator 7, a gearbox 8, a machine base 9, Coupling 10, die changing disc motor 11, frequency conversion motor 12, temperature controller 13, die changing disc 14; feeding hopper 1 is installed at the bottom of conveying belt 2; output of humidity sensor 3 is connected to input end of temperature controller 13, The output end of the temperature controller 13 is connected to the input end of the heating wire 4; the stirring blade 6 is a plurality of blades mounted on the same shaft, and the shaft rotates at a uniform speed under the drive of the stirring motor 5, and the stirring blade 6 is mounted on the granulator 7 for production. At the entrance of the material powder; the gearbox 8 is connected to the frequency conversion motor 12 through a coupling 10 to control the speed of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com