Rotary vane knife type vineyard ditcher

A rotary blade and vineyard technology, applied in the fields of soil preparation machinery, agricultural machinery and implements, applications, etc., can solve the problems of large forward resistance, offset of working parts, etc., and achieve the effect of convenient turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

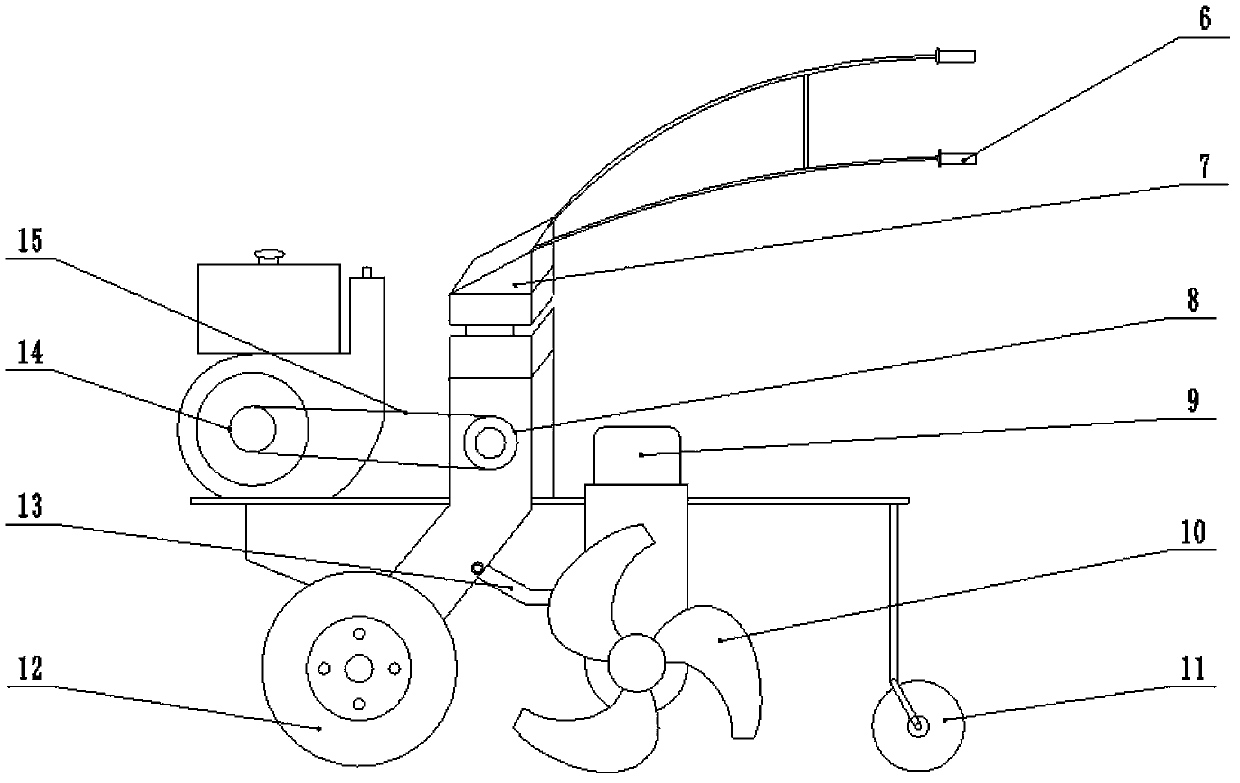

[0009] The rotary blade type vineyard ditching machine of the present invention is composed of engine 1, gearbox 2, drive chain 3, speed reducer sprocket 4, frame 5, armrest frame 6, armrest frame steering gear 7, driven pulley 8 , speed reducer 9, rotary vane cutter 10, depth-limiting wheel 11, travel wheel 12, fastening piece 13, driving pulley 14, transmission belt 15 etc. are formed. During work, engine 1 is fixed on the front end of frame 5 by bolts. The torque output by the engine 1 is driven by the driving pulley 14 through the transmission belt 15 to drive the driven pulley 8 to input power into the gearbox 2 to realize dual power output. A part of the mechanical energy provided by the engine 1 transmits the power to the road wheels 12 through the chain transmission, so as to provide driving force for the machine to move forward. The other part is driven by the sprocket on the right side of the gearbox through the transmission chain 3 to drive the reducer sprocket 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com