High and steep soil slope underneath pass parallel tunnel bias pressure treatment method and rapid measurement device

A technology for soil slopes and measuring devices, which can be used in tunnels, earthwork drilling, mining devices, etc., and can solve problems such as shaking, measurement errors, and confusion at the construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

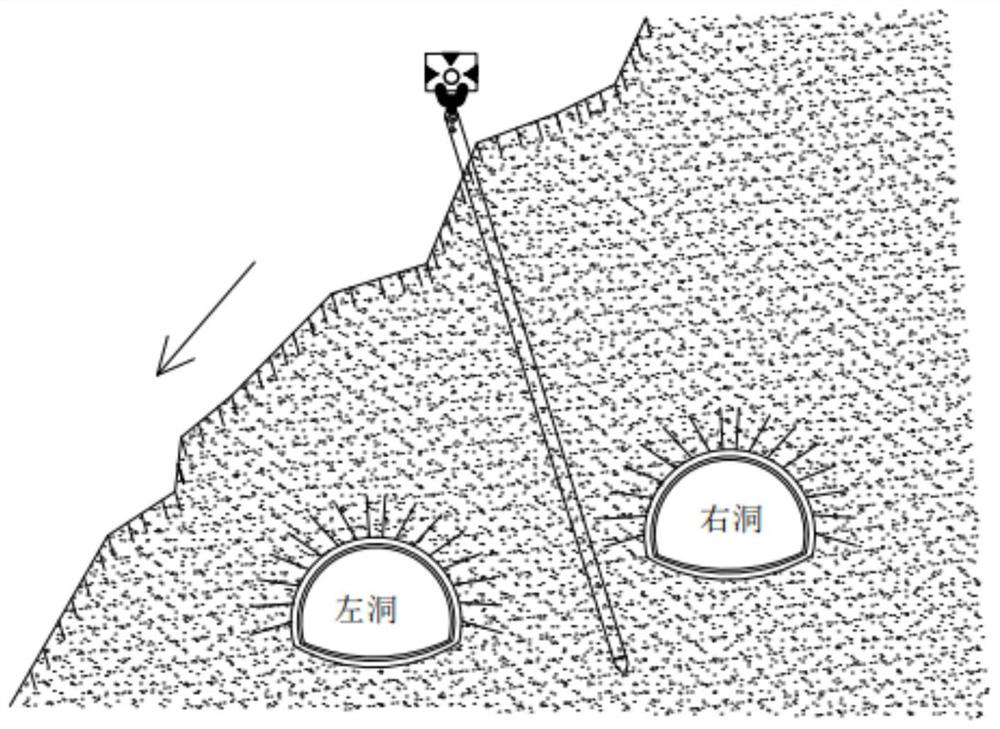

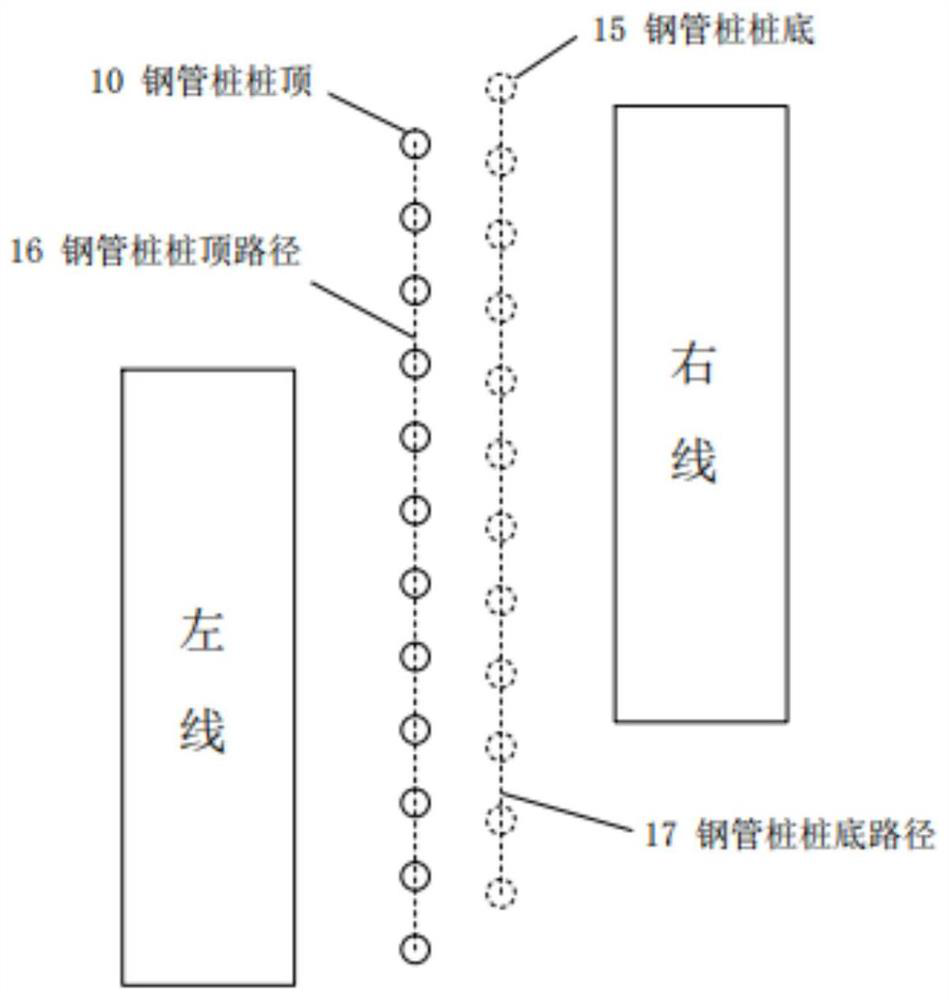

[0041] A certain tunnel project is a separated short tunnel crossing the mountain formed after the excavation of the mountain. The overall direction of the tunnel is about 310 meters. The hole is shallow buried side. The ridge crossed by the tunnel is high in the south and low in the north (such as figure 1 As shown), according to the analysis of bias conditions based on the lateral slope of the topography of the cave and the buried depth of the tunnel, there is a phenomenon of bias pressure in the tunnel; the excavation of the right hole has a footage of 8 meters and the left hole collapses when the left hole is excavated. After the excavation, the monitoring data in the cave changed greatly, and the side slope bias effect of the cave entrance was more obvious. Therefore, according to the tunnel design drawings, the steel pipe piles are obliquely pressed into the slope (such as figure 1 As shown), the expected route of the steel pipe pile 9 is pre-designed, the starting poi...

Embodiment 2

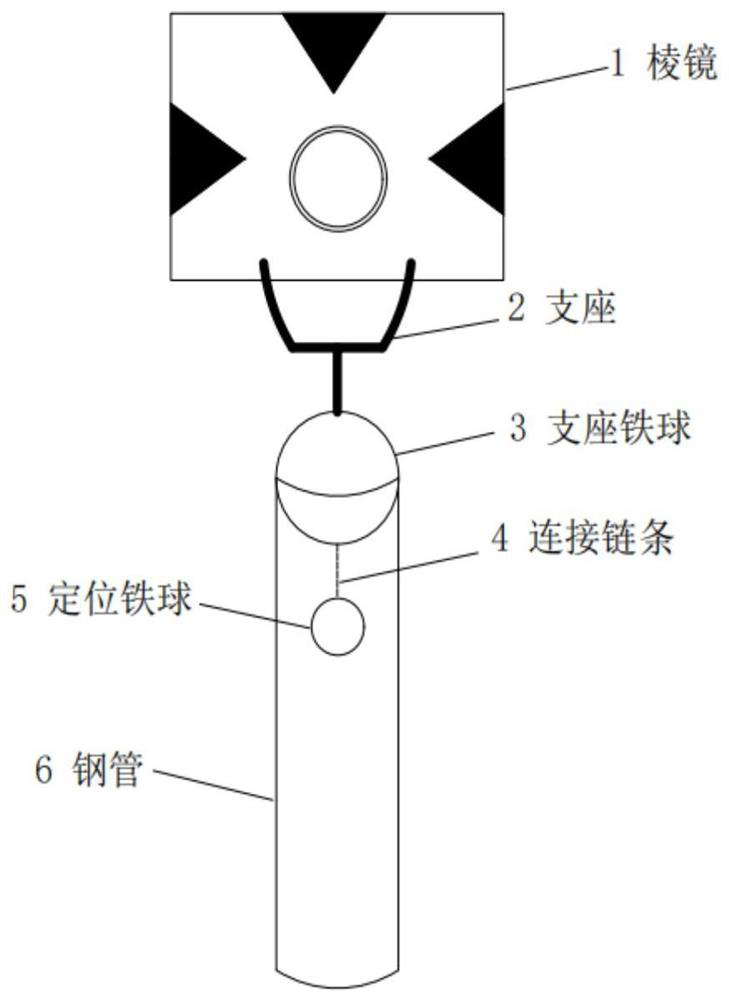

[0045] A bias pressure phenomenon occurs during the construction of a steeply inclined slope passing through a parallel tunnel with a small clear distance. Now, a fourth-order counter-pressure retaining slope is piled up at the entrance of the bias-pressure side as a support, and the second and fourth steps of the slope are set. Rapid measuring devices such as Figure 4 As shown, as the displacement observation measuring point. When the soil in the upper part of the right hole slides to the left side, the back pressure retaining slope is subjected to a downward force along the slope surface, and the steel pipe 6 on the slope shifts with the soil, causing the iron ball 3 of the upper support to follow the steel pipe 6 The position of the lower positioning iron ball 5 is driven by gravity to keep the upper support iron ball always in a vertical state, so that the coordinates of the center point of the upper prism are only caused by the sliding of the slope surface, which avoids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com