Face shovel excavating and loading device capable of increasing pushing force and journey of bucket hydraulic cylinder

A loading device and hydraulic cylinder technology, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of not being able to meet the structural and transmission requirements at the same time, and the structure of the excavator is single, so as to optimize the digging force, reduce production costs, Optimizing the effect of the lever arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

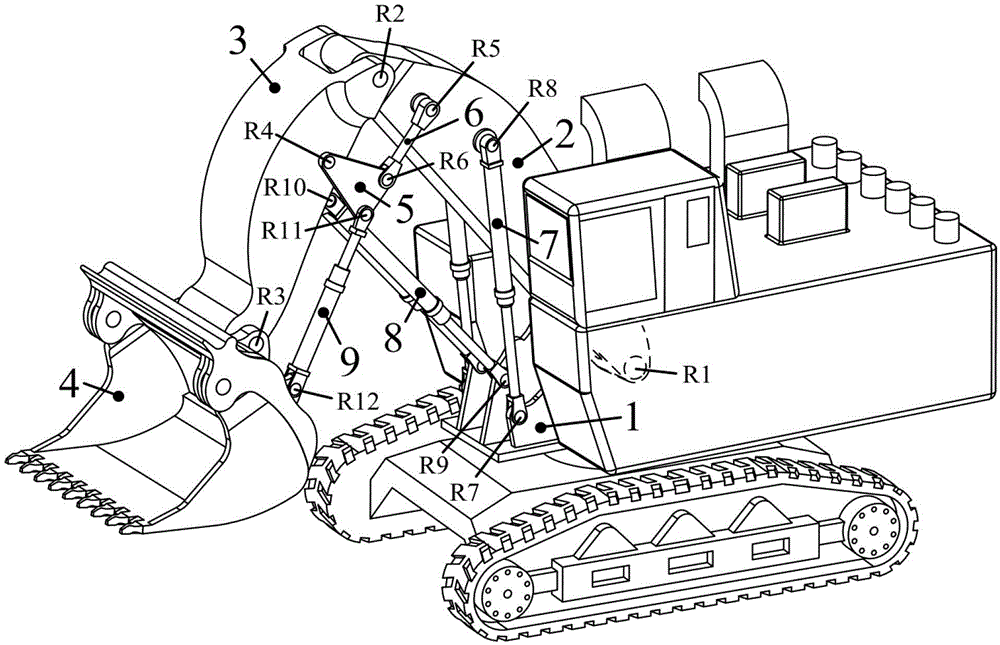

[0012] exist figure 1 In the schematic diagram of the front shovel digging and loading device that can increase the thrust and stroke of the bucket hydraulic cylinder, the lower end of the boom 2 is hinged to the frame 1 through the hinge R1, and the upper end of the boom is hinged to one end of the stick 3 through the hinge R2. The other end of the stick is hinged to a part of the bucket 4 through the hinge R3, and the ends of the cylinder liners of the pair of boom hydraulic cylinders 7 are respectively hinged to a part of the boom through the hinge R8, and the piston rods of the pair of boom hydraulic cylinders The end part is hinged with the frame through the hinge R7, the cylinder liner end of the pair of stick hydraulic cylinders 8 is hinged with the middle part of the above-mentioned stick through the hinge R10, and the piston rod ends of the pair of stick hydraulic cylinders are connected with the frame through the hinge R9. Hinged, a pair of bucket rockers 5 are symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com