Production method for rigid polyurethane foam from environment-friendly foaming agent and product thereof

A technology of rigid foam and blowing agent, which is applied in the field of polyurethane rigid foam preparation in the building materials insulation industry, which can solve the problems of catalyst usage restrictions and achieve the effects of overcoming unstable storage, good foam appearance and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

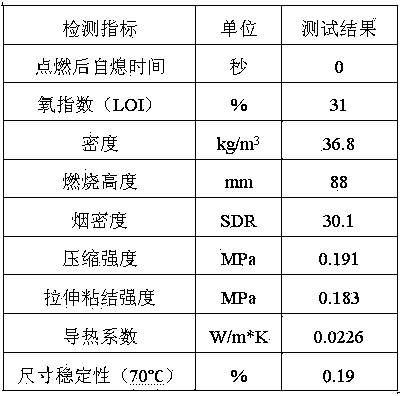

Examples

Embodiment 1

[0039] The present embodiment adopts batch process to prepare polyurethane rigid foam material:

[0040] Add 96 grams of HFE-254pc and 4 grams of HFC-227ea into the container, quickly seal it, and mix evenly to prepare a mixed foaming agent, which is kept refrigerated for use;

[0041] Mix 100 parts by weight of polyether polyol ZS-4110, 2 parts by weight of foam stabilizer L-6860, 1 part by weight of deionized water, and 0.5 parts by weight of catalyst Dabco EG, and stir evenly to prepare the combination A material. In industrial production, combination A material can also be stored for a long time;

[0042] The above two steps are in no particular order. Mix 103.5 grams of combination A material with 20 grams of mixed foaming agent, stir well, add 130 grams of isocyanate PM-200 to the mixture, take mechanical stirring and mixing in a low pressure foaming machine, and mix and stir at 1500rpm at 25°C 5 seconds. Then the mixture is poured into a transparent cup and molded, t...

Embodiment 2

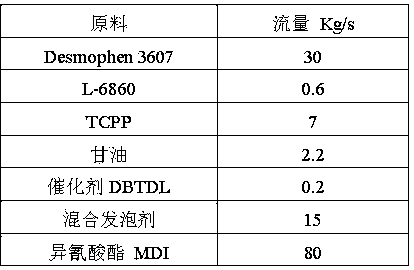

[0051] The present embodiment adopts continuous process to prepare polyurethane rigid foam material:

[0052] Add 96 grams of HFE-254pc and 4 grams of HFC-227ea into the container, quickly seal it, and mix evenly to prepare a mixed foaming agent, which is kept refrigerated for use;

[0053] Fill polyols Desmophen 3607, L-6860, flame retardant TCPP, glycerin, catalyst DBTDL, isocyanate MDI, and mixed blowing agent (HFE-254pc / HFC-227ea) into their respective storage tanks. Adjust the outlet flow control of each storage tank respectively as shown in Table 2, and the flow of each raw material is controlled by a flow meter.

[0054] 【Table 2】

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com