Method for improving adsorption selectivity of sodium polyacrylat oil dewatering material

A selective adsorption and oil technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of easy blockage of adsorption pores, short service life, difficulty in balancing dehydration efficiency and selectivity, etc. problems, to achieve the effect of increasing the adsorption rate and achieving balance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

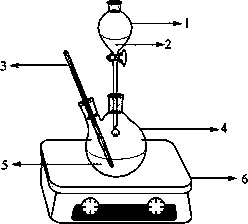

[0017] Specific implementation according to the appended figure 1 Follow the steps shown:

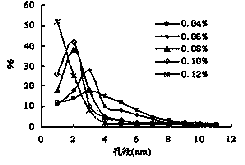

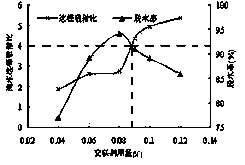

[0018] 1. Preparation steps of a series of adsorbent materials: add 60mL cyclohexane and 2mL cetyl alcohol phosphate into 6 flasks respectively, and pass nitrogen gas to drive out the oxygen in the bottles, and raise the temperature to 60°C to dissolve them. At the same time, 7.5g of acrylic acid was placed in 6 conical flasks, neutralized with a 41% NaOH solution to the acrylic acid monomer weight under cooling conditions, and 0.6% of the acrylic acid monomer weight was added to the conical flasks. Potassium sulfate is used as an initiator, and then respectively continue to add N, N'-methylenebisacrylamide with a weight of 0.04%, 0.06%, 0.08%, 0.09%, 0.10%, and 0.12% of acrylic acid monomers as a crosslinking agent, blowing Enter nitrogen, pour the mixed solution into the dropping funnel, drop the mixed monomer in the dropping funnel into the flask at a speed of 1-2dr / s, and then reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com