Sensing element with unevenly distributed magnet sheets in shell

A technology of evenly distributed, sensing elements, applied in vehicle components, instruments, speed/acceleration/shock measurement, etc., can solve the problems of different, easily damaged permanent magnet blocks, inconsistencies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

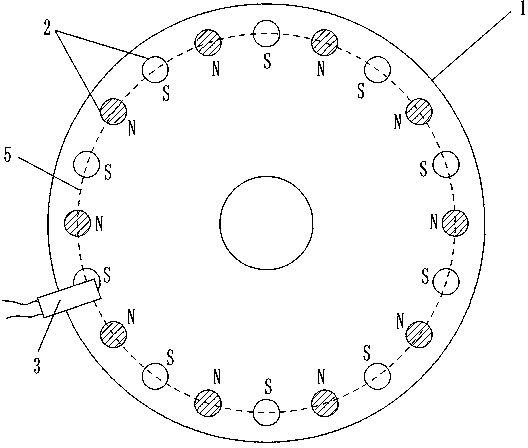

[0060] Example 1. Sensing element with evenly distributed multi-magnetic sheets in a polyurethane-cast housing for holding magnetic sheet layers

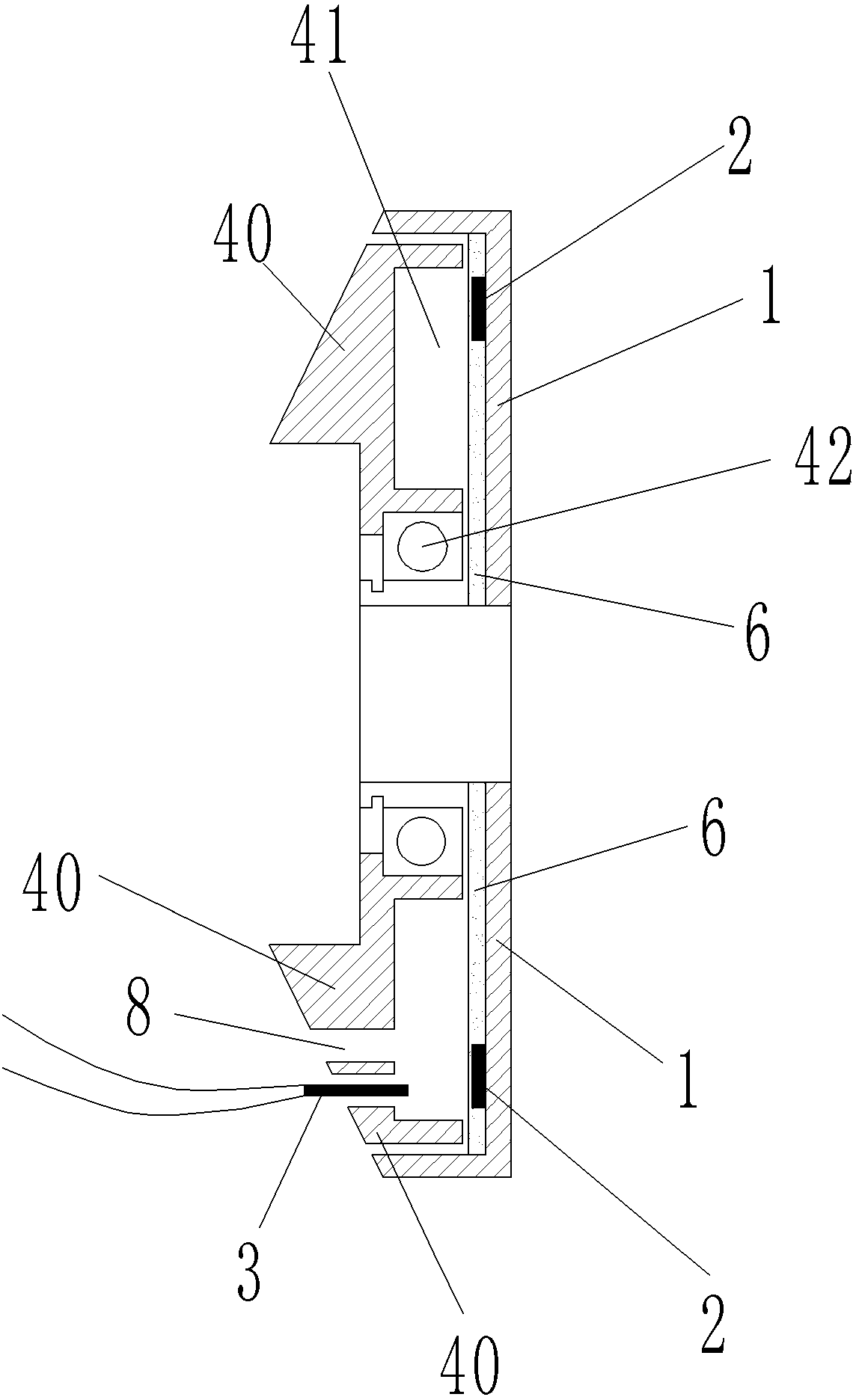

[0061] Such as figure 1 , 3 , With an annular groove rotating disc 1 and an annular groove fixing disc 40 with opposite concave surfaces, the size of the annular groove rotating disc 1 and the annular groove fixing disc 40 is just such that the annular groove fixing disc 40 can fit in Annular groove rotating disc 1 in the annular groove, the two discs can be relatively rotatable fitting inner hollow shell, the concave surface of the two discs sandwiched into a hollow ring 41; the ring groove rotating disc at the position of the hollow ring 41 20 permanent magnet pieces 2 are pasted and fixed on 1. On the surface of the annular groove rotating disc 1 with the permanent magnet sheet 2 and the surface of the permanent magnet sheet 2, there is also a pinching magnetic sheet layer 6. The permanent magnet sheet 2 is clamped and fixed between...

Embodiment 2

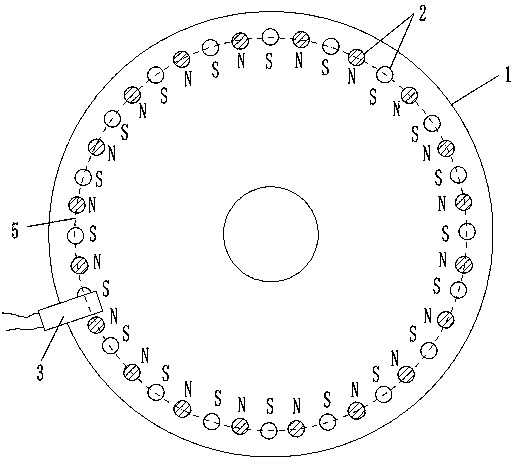

[0070] Embodiment 2. Sensing element with uniform distribution of multiple magnetic sheets in a high-density housing

[0071] Such as figure 2 , 3 , The annular groove rotating disc 1 in the hollow ring 41 has a diameter of 10.0 cm, and 40 permanent magnet pieces 2 are arranged on the annular groove rotating disc 1. The 40 permanent magnet pieces 2 each have a diameter of 0.6 cm. The thickness is 0.2mm, and the magnetic flux is 146---279(B·H)max / KJ·m -3 One of the values in. The Hall 3 maintains an interval of 0.2 cm from each permanent magnet plate 2 in the rotating state, so that when each rotating permanent magnet plate 2 passes through the Hall 3, the Hall 3 can generate a corresponding rectangular wave electrical signal output. The structure of other rotating disk 1, permanent magnet plate 2, and Hall 3 is the same as that of the first embodiment.

Embodiment 3

[0072] Embodiment 3. A sensor element with evenly distributed multiple magnetic sheets in the housing of the aluminum plate for holding the magnetic sheet layer

[0073] Such as figure 1 , 3 , With an annular groove rotating disc 1 and an annular groove fixing disc 40 with opposite concave surfaces, the size of the annular groove rotating disc 1 and the annular groove fixing disc 40 is just such that the annular groove fixing disc 40 can fit in Annular groove rotating disc 1 in the annular groove, the two discs can be relatively rotatable fitting inner hollow shell, the concave surface of the two discs sandwiched into a hollow ring 41; the ring groove rotating disc at the position of the hollow ring 41 20 permanent magnet pieces 2 are pasted and fixed on 1. On the surface of the annular groove rotating disc 1 with the permanent magnet sheet 2 and the surface of the permanent magnet sheet 2, there is also a pinching magnetic sheet layer 6. The permanent magnet sheet 2 is clamped a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com