Closed cleaning technology for oil reservoir and device adopting closed cleaning technology

A technology for oil storage tanks and processes, which is applied in the closed cleaning process of oil storage tanks and its equipment to achieve the effects of improved safety, convenient transportation, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

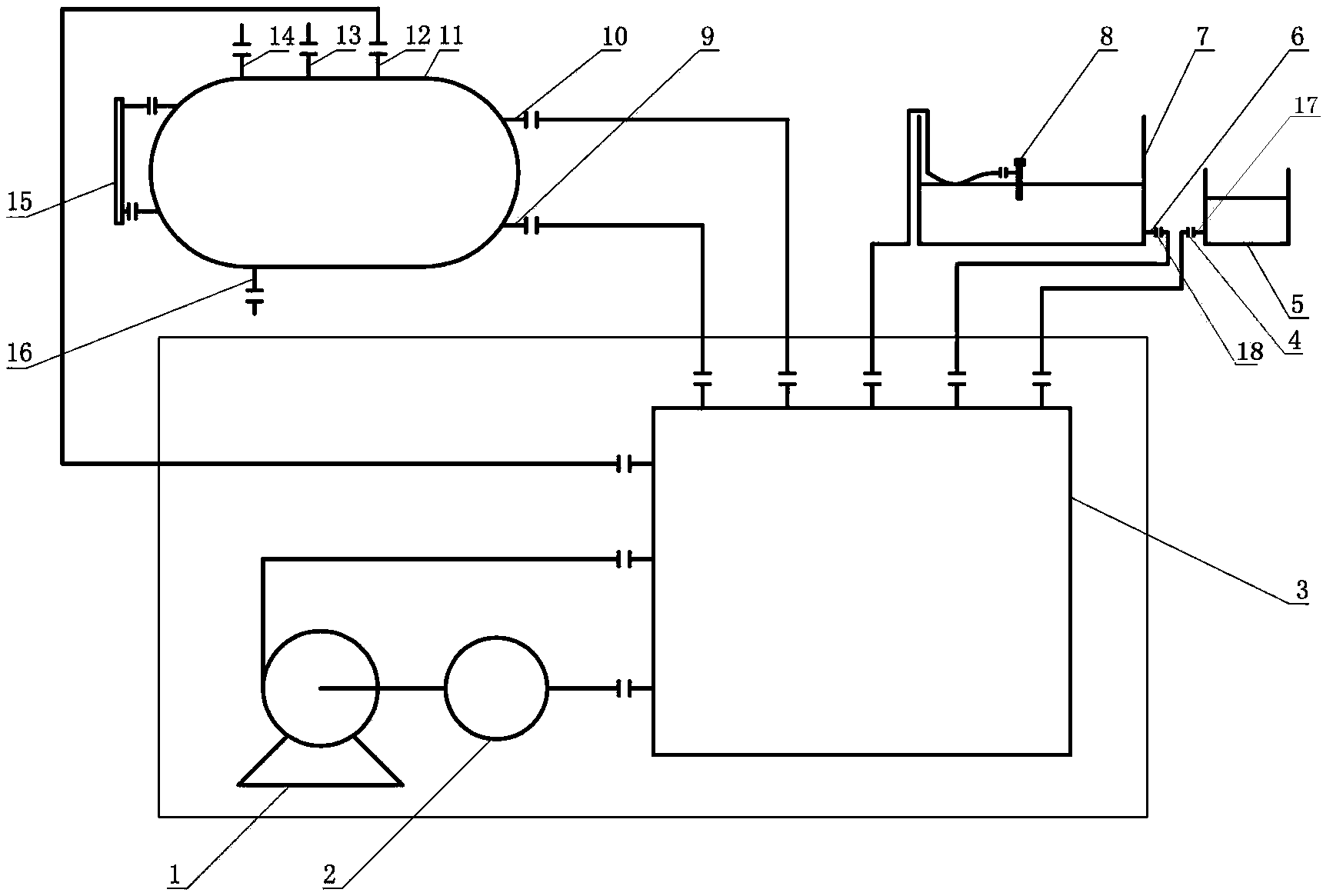

[0022] A closed cleaning device for an oil storage tank, comprising a cleaned oil tank 7, an oil storage tank 5, a process valve island 3, a pressure pump 1, a vacuum heat exchange type oil-water separator 11, the cleaned oil tank 7 and the oil storage tank The bottom of 5 is equipped with blowdown pipe 6,17 respectively, and valve 18,4 is respectively installed on blowdown pipe 6,17. The vacuum heat exchange type oil-water separator 11 is respectively equipped with a vacuum connecting pipe 13 with a valve, a steam connecting pipe 16, an oil outlet pipe 12, a separator outlet pipe 9, a separator inlet pipe 10 and a liquid level gauge 14. The blowdown pipe 6 at the bottom of the cleaned oil tank 7 is connected to the process valve island 3 through valves and pipelines, the process valve island 3 is connected to a cleaning machine 8 through valves and pipelines, and the blowdown pipe of the oil storage tank 5 is connected through valves and pipes. The pipeline is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com