Aluminum alloy cable

A technology of aluminum alloy and aluminum alloy conductors, which is applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of electrochemical corrosion at the joints, uneven bolt materials, and small bolt pressing force, etc., to achieve electrical conductivity Excellent performance, no memory effect, and improved elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

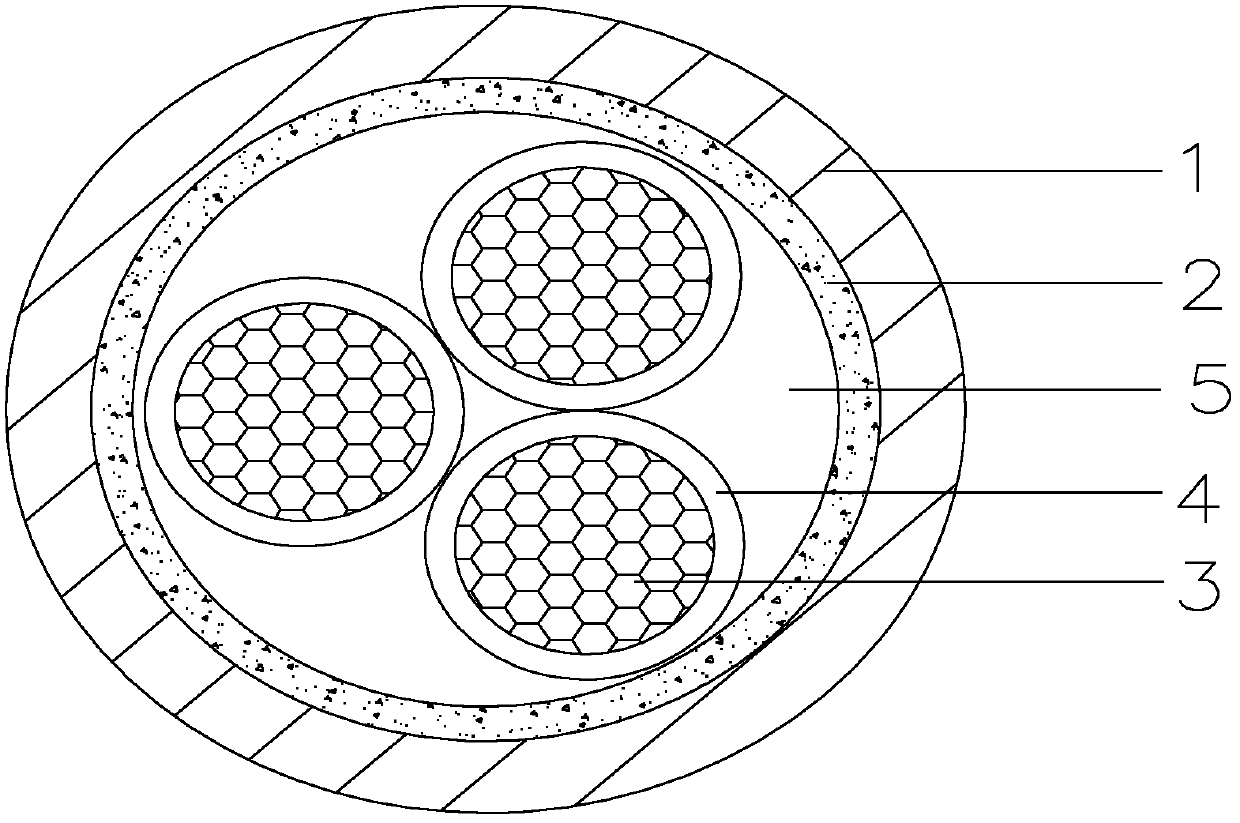

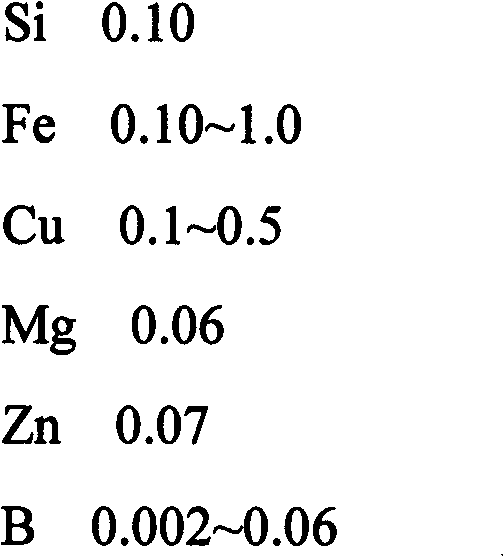

[0023] A three-core aluminum alloy cable with a structure such as figure 1 As shown, it includes tape 2, sheath 1, insulated wire core and filler 5. The sheath 1 is wrapped outside the tape 2, the insulated wire core is arranged inside the tape 2, and the filler 5 is arranged between the insulated wire core and the bag. In the gap between the strips 2, the insulated wire core is composed of an aluminum alloy conductor 3 and an insulating layer 4 wrapped around the aluminum alloy conductor 3. There are three insulated wire cores. Aluminum alloy conductor 3 is 8030 aluminum alloy conductor material. The 8030 aluminum alloy conductor includes the following components by weight:

[0024]

[0025] The balance is aluminum and unavoidable other elements, and the total content of other elements is 0.20.

[0026] The resistivity of aluminum alloy conductor 3 is 61%IACS, the tensile strength in soft state is 56-111Mpa, the density is 2.71g / cm3, the elongation is 15-25%, and the an...

Embodiment 2

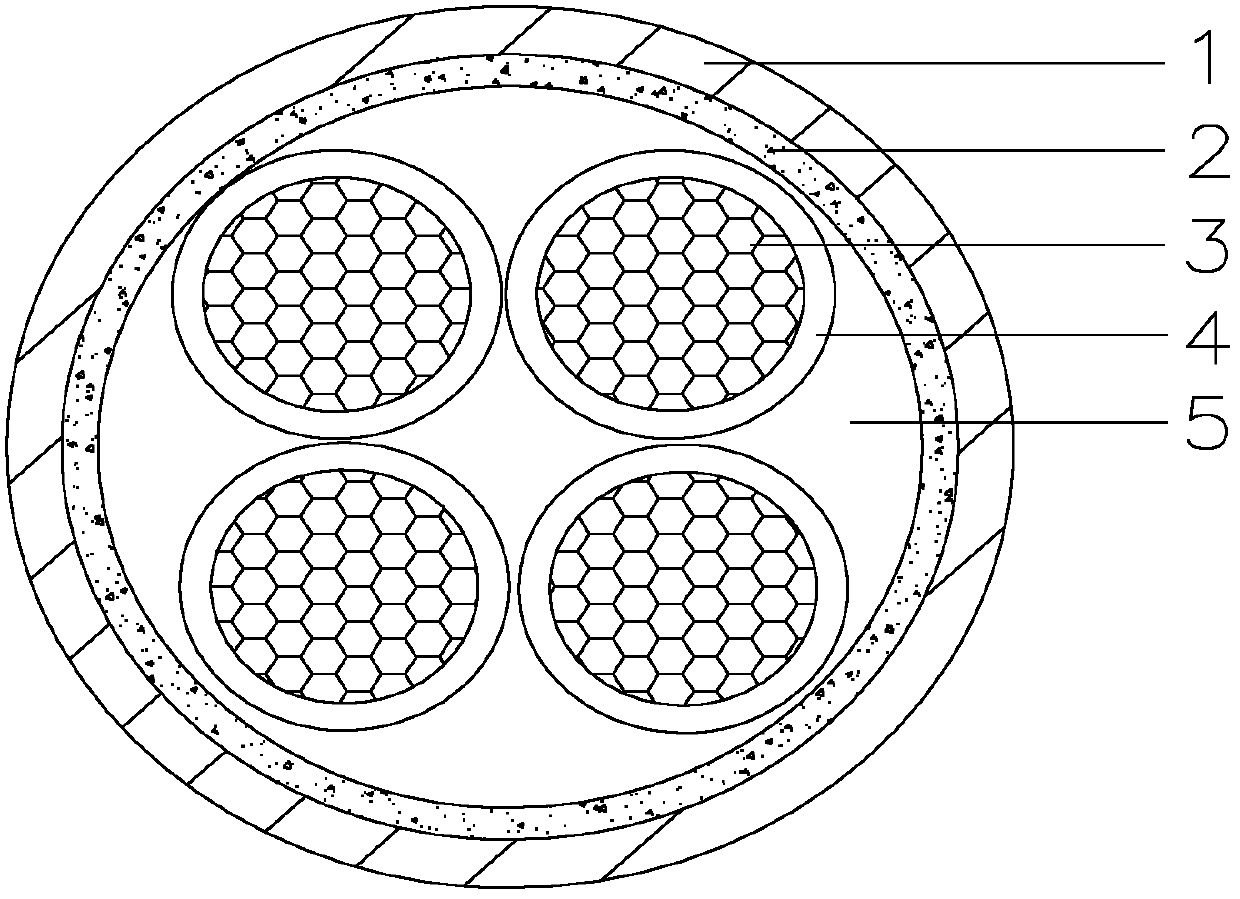

[0028] A four-core aluminum alloy cable with a structure such as figure 2 As shown, it includes tape 2, sheath 1, insulated wire core and filler 5. The sheath 1 is wrapped outside the tape 2, the insulated wire core is arranged inside the tape 2, and the filler 5 is arranged between the insulated wire core and the bag. In the gap between the strips 2, the insulated wire core is composed of an aluminum alloy conductor 3 and an insulating layer 4 wrapped around the aluminum alloy conductor 3. There are four insulated wire cores. Aluminum alloy conductor 3 is 8030 aluminum alloy conductor material.

[0029] The 8030 aluminum alloy conductor includes the following components by weight:

[0030]

[0031] The balance is aluminum and unavoidable other elements, and the total content of other elements is 0.20.

[0032] The resistivity of aluminum alloy conductor 3 is 61%IACS, the tensile strength in soft state is 56-111Mpa, the density is 2.71g / cm3, the elongation is 15-25%, an...

Embodiment 3

[0034] An aluminum alloy cable with a structure such as figure 1 As shown, the product model specification is YJLHV-1kV 3*35mm2; main process parameters: 1. Aluminum alloy conductor structure: 1+6+12 / 19 wires / single wire diameter 2.53mm; 2. The thickness of the cross-linked polyethylene insulating layer : 1.0mm; 3. Tape: (number of layers*thickness) 2*0.2; 4. Sheath thickness: 1.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com