Device and method for preparing ethanol through acetic acid or acetic ester catalytic hydrogenation reaction

A technology of catalytic hydrogenation and acetate, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of large hydrogen circulation, reduce the hydrogen-acid ratio of the system, and high energy consumption of compression, and achieve good results Technical economy, the effect of reducing the hydrogen-acid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

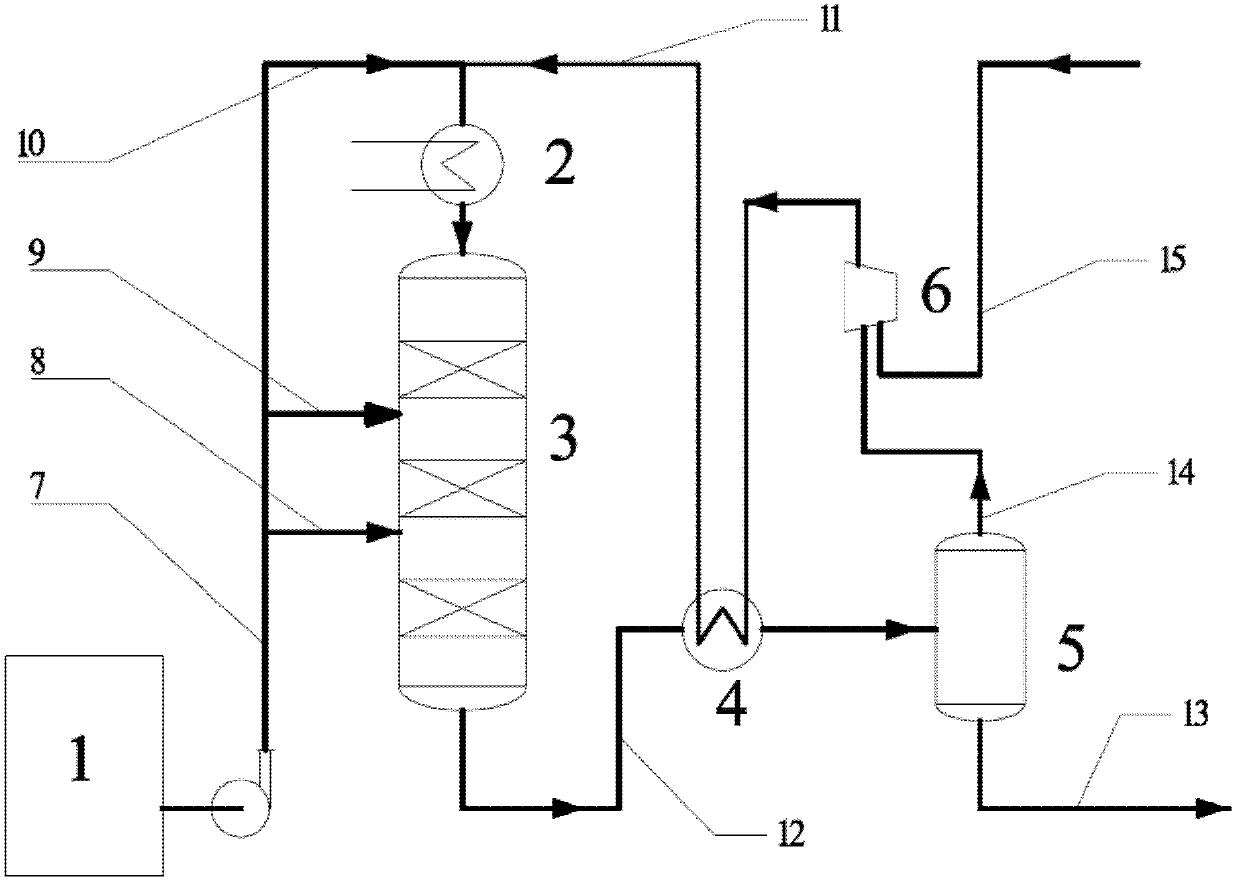

[0026] Such as figure 1 Shown: a device for preparing ethanol by catalyzing hydrogenation reaction of acetic acid or acetate, comprising a raw material storage tank 1, a heater 2, a reactor 3, a heat exchanger 4, a gas-liquid separator 5, and a hydrogen circulation compressor 6. The reactor 3 described above contains three-stage reaction zones, and the reaction zones at all levels are arranged in series from top to bottom. The flow inlet of each reaction zone is connected to the raw material storage tank 1 through a pipeline, and the hydrogen circulation compressor 6 is passed through The hydrogen circulation pipeline is connected to the heat exchanger 4 and the heater 2 in turn, and then connected to the top of the reactor 3. The raw material storage tank 1 is respectively connected to each reaction zone of the reactor 3 through three parallel raw material delivery pipelines, one of which is a raw material delivery pipeline The pipeline is connected in parallel with the hydro...

Embodiment 2

[0035] according to figure 1 As shown, the process flow of the present invention is adopted, the catalyst is a platinum metal carrier composite, and the three-stage catalyst bed is filled with catalysts of the same weight. The feed materials are acetic acid with a purity of 99.7wt% and hydrogen with a purity of 99.8%. The inlet temperature of the catalytic bed in the first-stage reaction zone of the reactor is 200°C, the reaction pressure is 1.5MPa, and the reaction weight space velocity is 0.1 hour -1 , the molar ratio of hydrogen to acid is 120:1; the reaction temperature at the inlet of the catalytic bed in the second-stage reaction zone of the reactor is 200°C, the reaction pressure is 1.48MPa, and the reaction weight space velocity is 0.1 hour -1 ; The reaction temperature at the inlet of the catalytic bed in the third-stage reaction zone of the reactor is 200°C, the reaction pressure is 1.46MPa, and the reaction weight space velocity is 0.1 hour -1 ; The mass ratio of t...

Embodiment 3

[0042] according to figure 1 As shown, adopting the technological process of the present invention, the catalyst is a platinum metal carrier composite, which is composed of a platinum metal carrier composite, and the three-stage catalytic bed is filled with catalysts of the same weight. The feed material is acetic acid with a purity of 99.7wt% and hydrogen with a purity of 99.8%. The inlet temperature of the catalytic bed in the first-stage reaction zone of the reactor is 350°C, the reaction pressure is 3.0MPa, the reaction weight space velocity is 0.7 hours-1, and the moles of hydrogen acid The ratio is 20:1; the reaction temperature at the inlet of the catalytic bed in the second-stage reaction zone of the reactor is 350°C, the reaction pressure is 2.98MPa, and the reaction weight space velocity is 0.7 hours-1; the reaction at the inlet of the catalytic bed in the third-stage reaction zone of the reactor The temperature is 350°C, the reaction pressure is 2.96MPa, and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com