Numerically-controlled machine oil-mist recycling machine

A technology of CNC machine tools and recycling machines, applied in metal processing machinery parts, maintenance and safety accessories, combined devices, etc., can solve problems such as large oil mist of cutting oil, physical and mental health hazards of employees, and environmental pollution in workshops, and achieve good results. Simple structure, the effect of physical and mental health protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

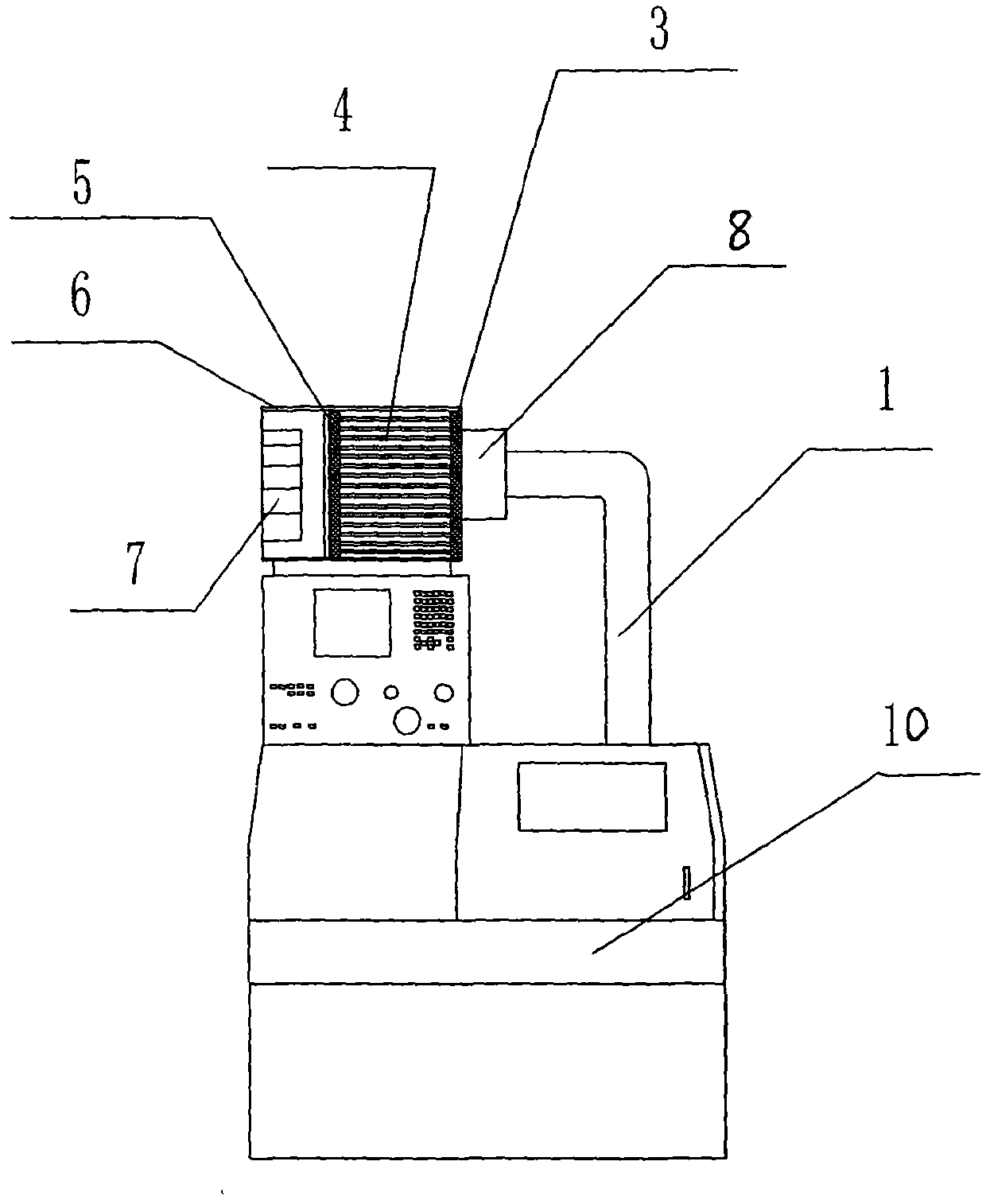

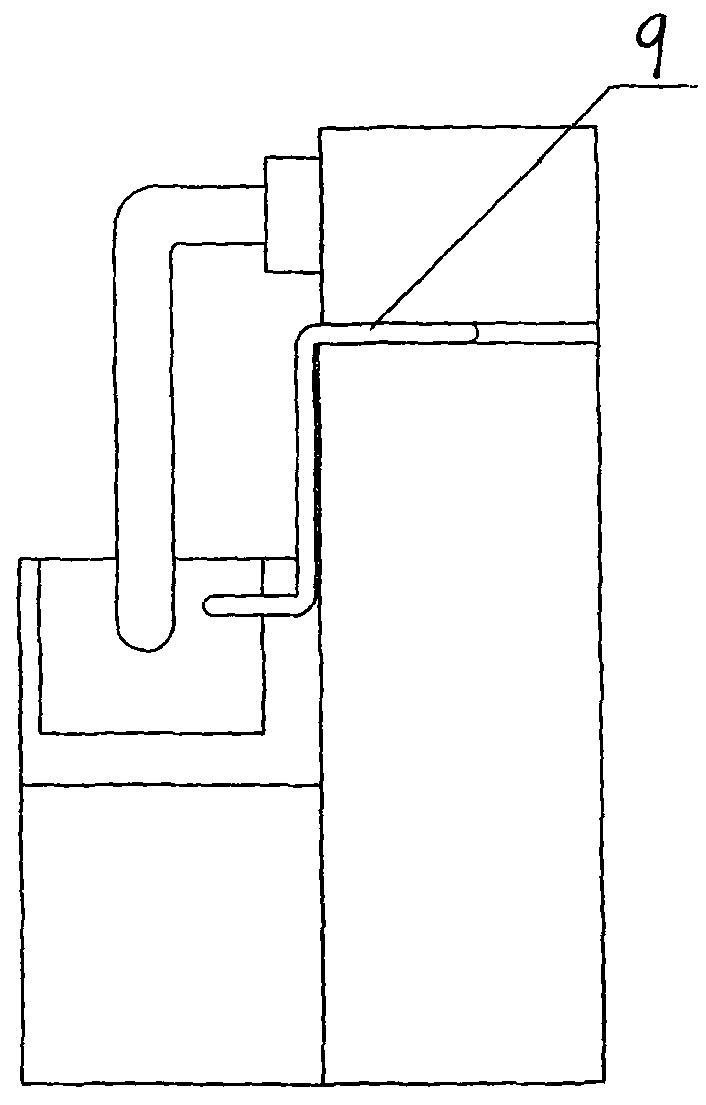

[0012] An oil mist recovery machine for a numerically controlled machine tool, comprising a filter 8, an intake pipe 1 and an oil discharge pipe 9, the filter 8 comprising an ionizer 4, a collector 2, and a fan 7, the collector 2 is arranged at the front end of the ionizer 4, and the fan 7 It is arranged at the rear end of the ionizer 4 , and the front and rear of the collector 2 are respectively equipped with a pre-filter 3 and a post-filter 5 , and an exhaust hole 6 is provided on the casing of the fan 7 . One end of the intake pipe 1 is connected to the collector 2, the other end of the intake pipe 1 is arranged in the machine tool 10, and one end of the oil discharge pipe 9 is connected to the ionizer 4.

[0013] Connected and communicated, the other end of the oil discharge pipe 9 returns to the machine tool 10 and is connected with the oil storage device provided in the machine tool 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com