Vertical rolling mill with press roll device

A pressure roller device and technology of vertical roller mills, which are applied in the field of vertical roller mills, can solve the problems of not solving different rolling shapes, etc., and achieve the effects of eliminating the need for lifting devices, high production efficiency, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments further illustrate the present invention in conjunction with the accompanying drawings.

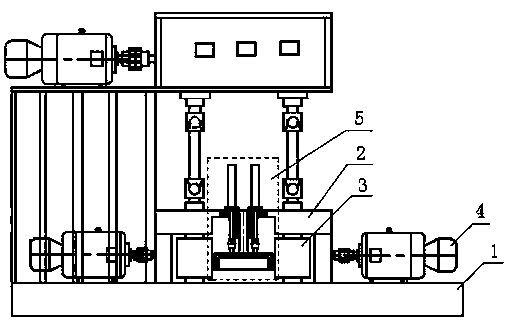

[0028] see figure 1 , a vertical rolling mill with a pressure roller device, including a rolling mill body composed of a base 1, a rolling mill stand 2 arranged on the base 1, a vertical roll 3 and a drive system 4, and a rolling mill body arranged between the rolling mill stands 2 The pressure roller device 5.

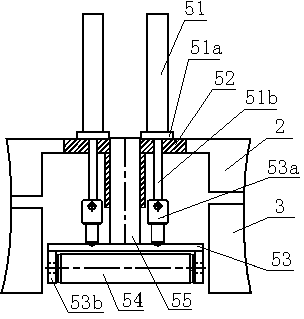

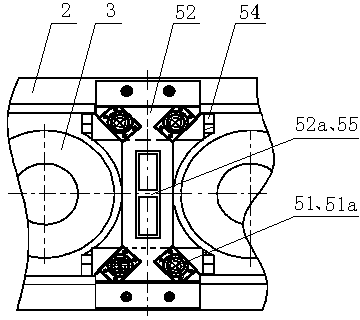

[0029] see Figures 2 to 5 The pressure roller device 5 includes an oil cylinder 51 , an upper beam 52 , a lower beam 53 , a pressure roller 54 and a guide cylinder 55 . There are four oil cylinders 51, which are symmetrically arranged on the four corners of the upper beam 52 through the pressing plate 51a. The piston rod 51b of the oil cylinder 51 passes through the upper beam 52 and is connected to the connecting rod 53a fixed on the upper part of the lower beam 53. The oil cylinder 51 adopts a servo valve or a synchronization valve. Control,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com