Thin-plate-type rotating ultrasonic motor

An ultrasonic motor and thin plate technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the disadvantages of miniaturization, miniaturization, limited application range, and unfavorable design and processing problems, to achieve the effect of compact structure and simple driving circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

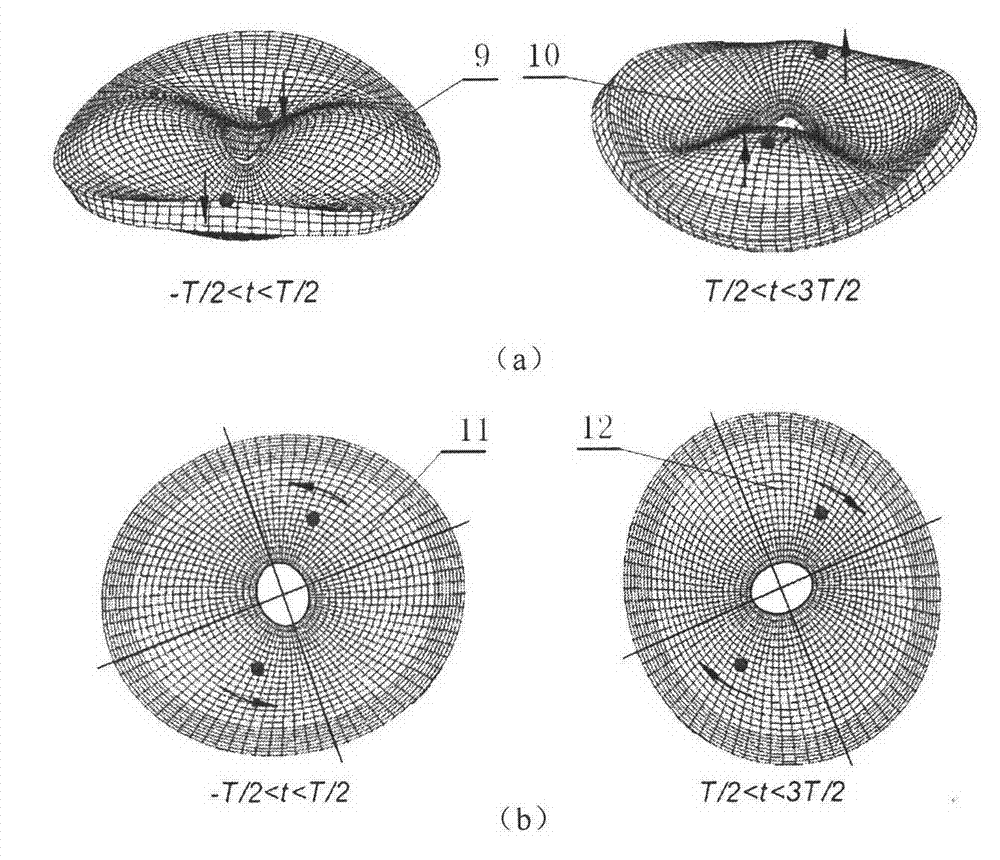

[0013] The working principle and specific implementation of the thin-plate double traveling wave rotary ultrasonic motor will be described below by taking the number of partitions of the fan-shaped silver-plated electrode 8 as 8 as an example.

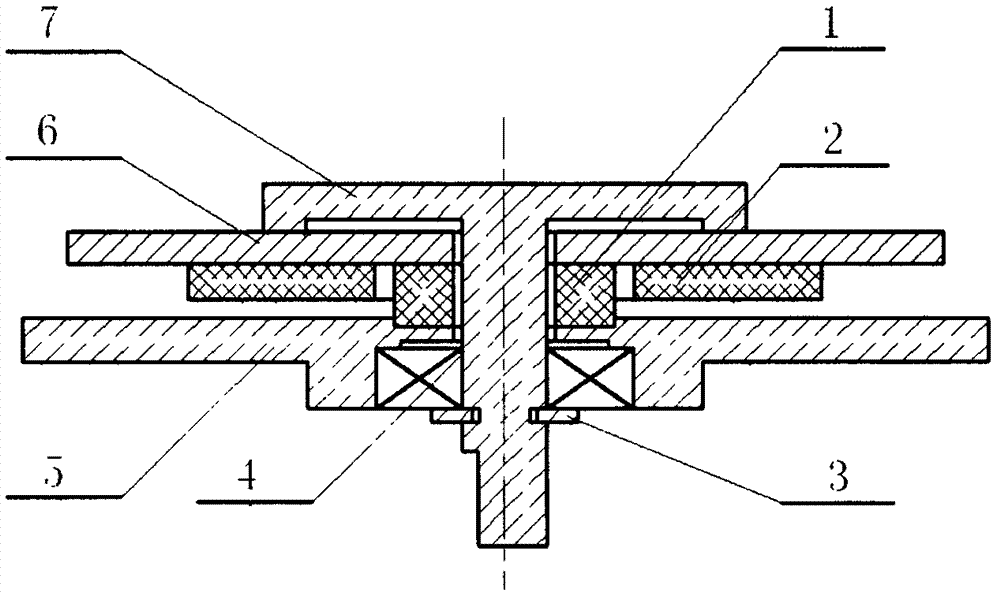

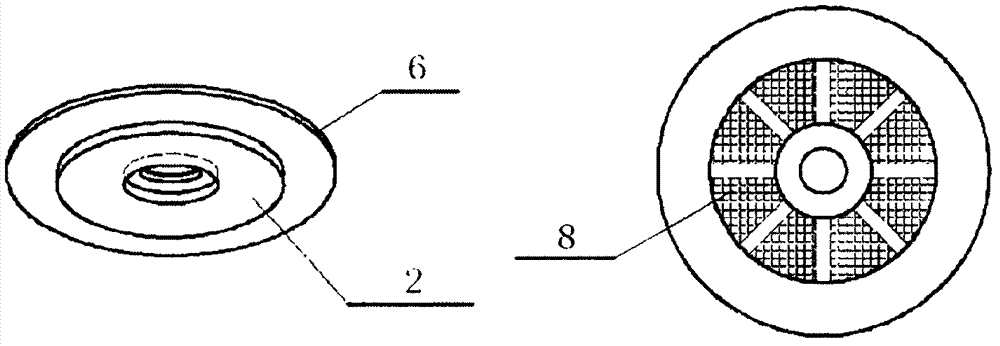

[0014] Such as figure 1 , figure 2 As shown, the thin-plate double traveling wave rotary ultrasonic motor of the present invention is mainly composed of a stator assembly, a rotor and a bracket assembly. The stator assembly adopts a composite structure of an annular thin metal sheet 6 and an annular piezoelectric ceramic sheet 2 . The piezoelectric ceramic ring is unidirectionally polarized and has eight evenly partitioned fan-shaped silver-plated electrodes 8; the rotor 7 and the base 5 are positioned by the bearing 4; the rubber spring 1 is pressed between the stator and the base 5 to fix the stator and provide a , The pre-pressure between the rotors. The thin-plate double-traveling-wave rotary ultrasonic motor of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com