Circuit breaker

A circuit breaker, high-voltage circuit breaker technology, applied in the direction of high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc., can solve the problems of slow mechanical contact actuation and/or arc extinguishing performance, complex settings, etc., to achieve reliable Effect of electrical connection, fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Description of the figure:

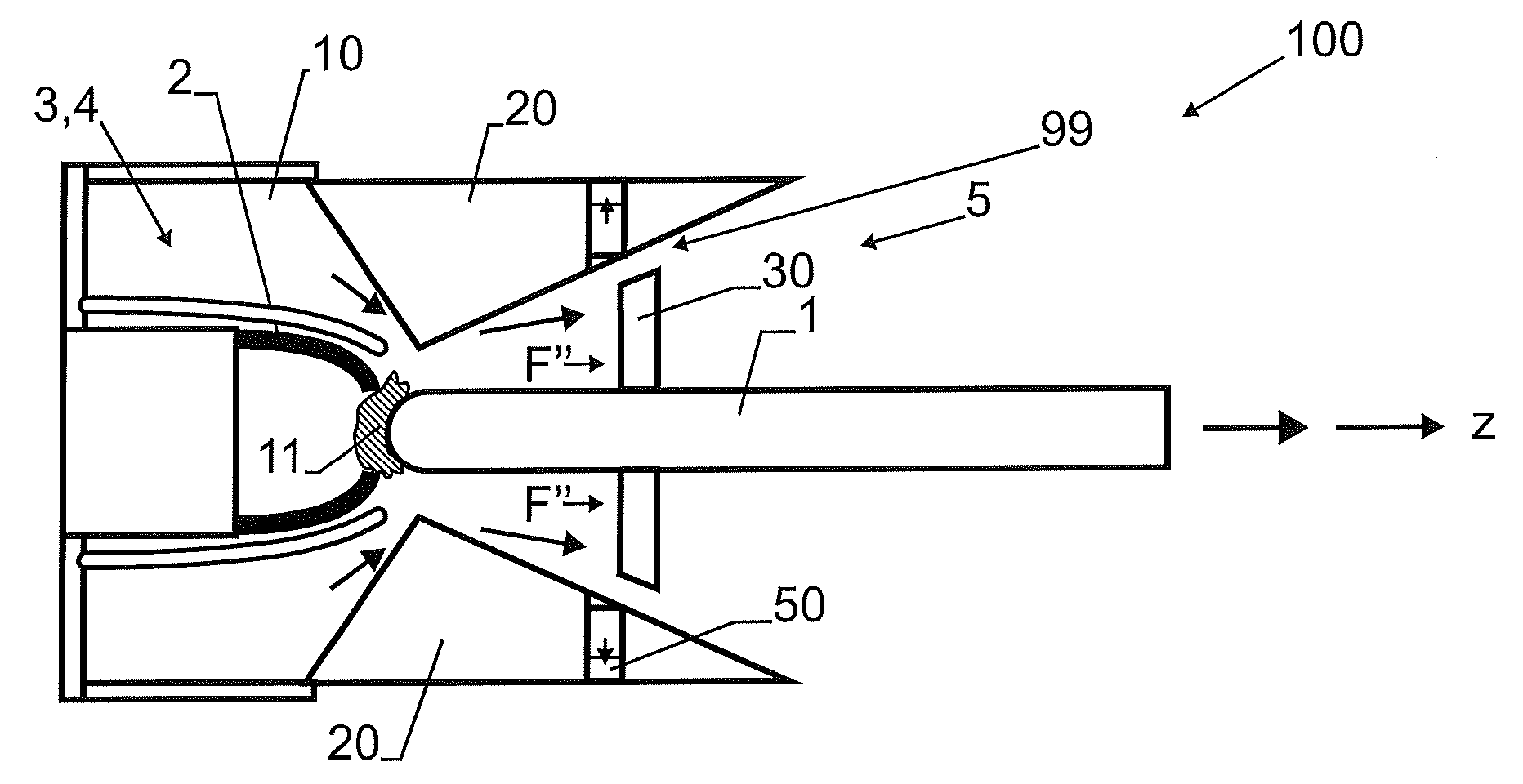

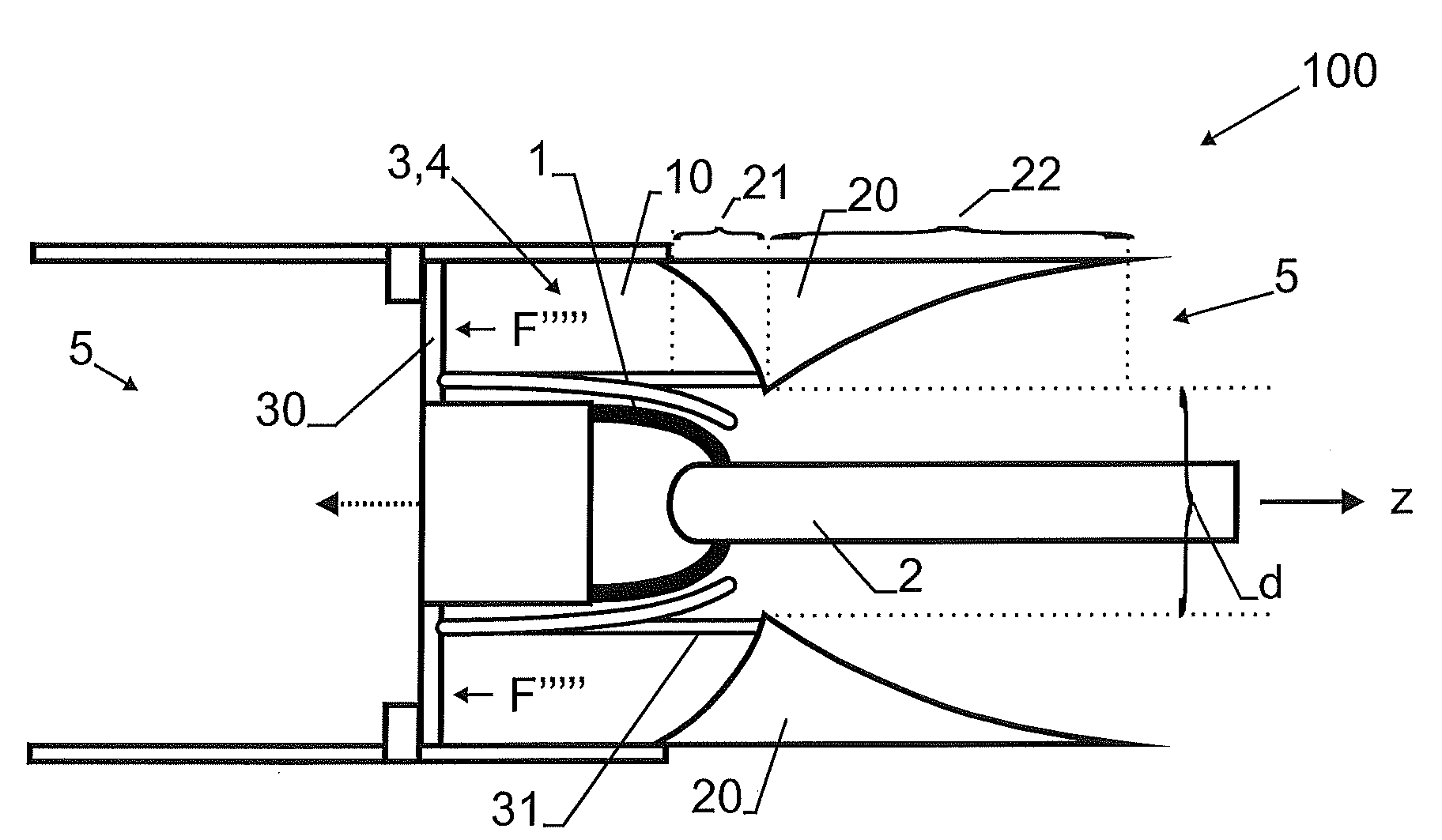

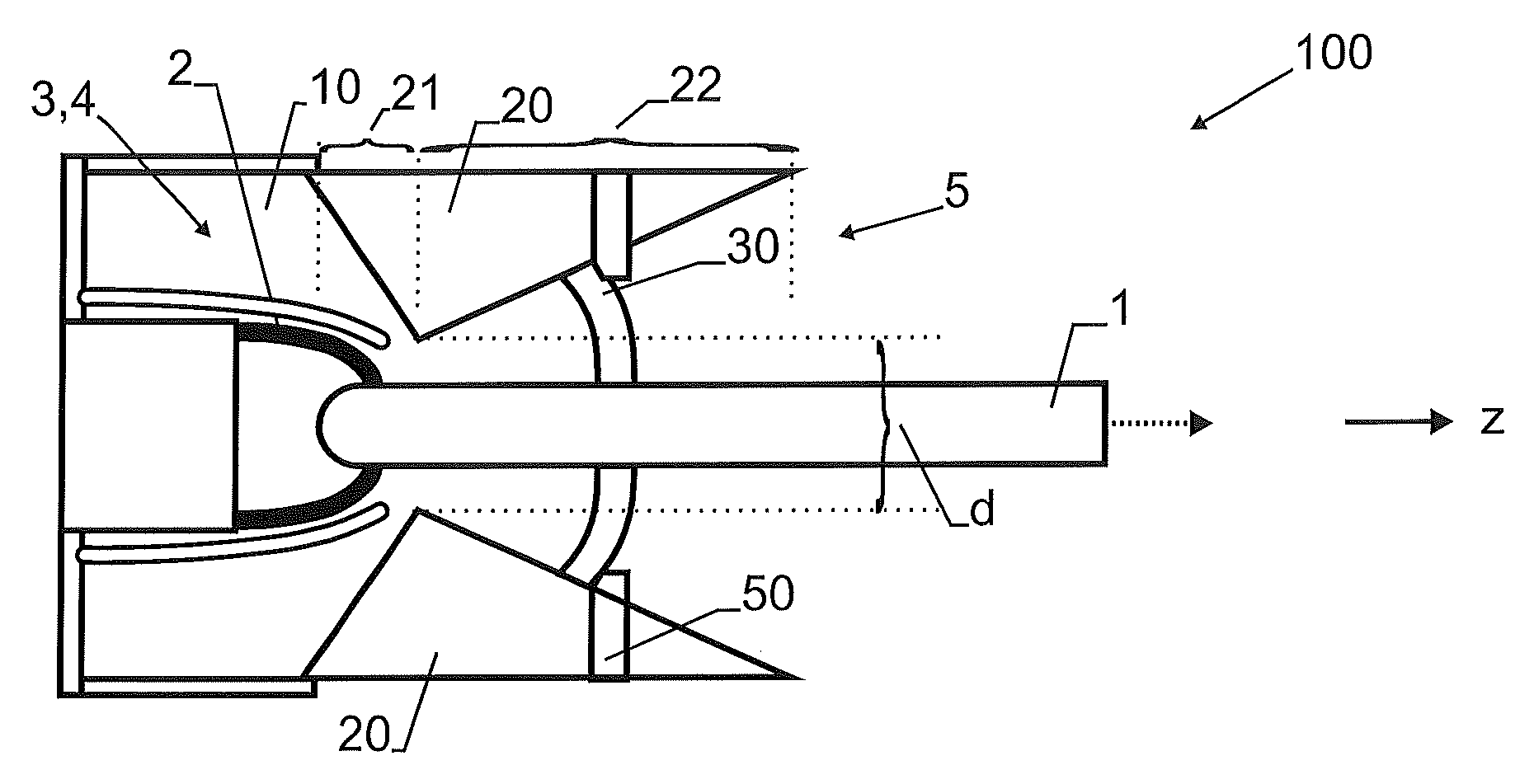

[0039] Figure 1a A cross-section through the first embodiment of the circuit breaker 100 is shown in the closed position. The circuit breaker 100 comprises a first arcing contact 1 and a second arcing contact 2 arranged coaxially (about the axis of symmetry z) in a tulip-plug configuration. The first arcing contact 1 is in the first position, ie electrically connected to the second arcing contact 2 . The quenching fluid (e.g. process air) 10 is provided in the pressure chamber 4 (wherein its volume e.g. is 3 liters), the pressure chamber 4 and the arcing chamber 3 of the circuit breaker 100 match. The term "arcing chamber" relates to the volume of the circuit breaker in which an electric arc is formed between the first and second arcing contacts 1 , 2 during separation of the arcing contacts 1 , 2 . The arc extinguishing or pressure chambers 3 , 4 are delimited on one side by a sealing wall 30 providing fluid tightness. The sealing wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com