Cart walking trolley with broken shaft protection device

A technology for protection devices and broken shafts, which is applied in the direction of safety devices, traveling mechanisms, and heavy-duty blocks, can solve problems such as wheel rim wear, difficult wheels, and crane collapse, so as to reduce friction, reduce the probability of rail gnawing, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

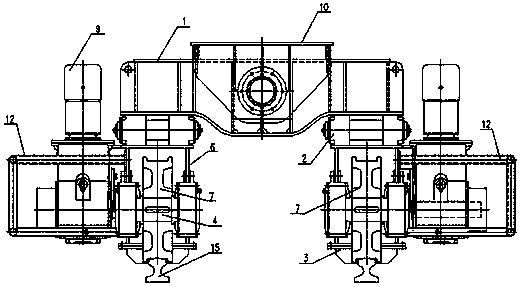

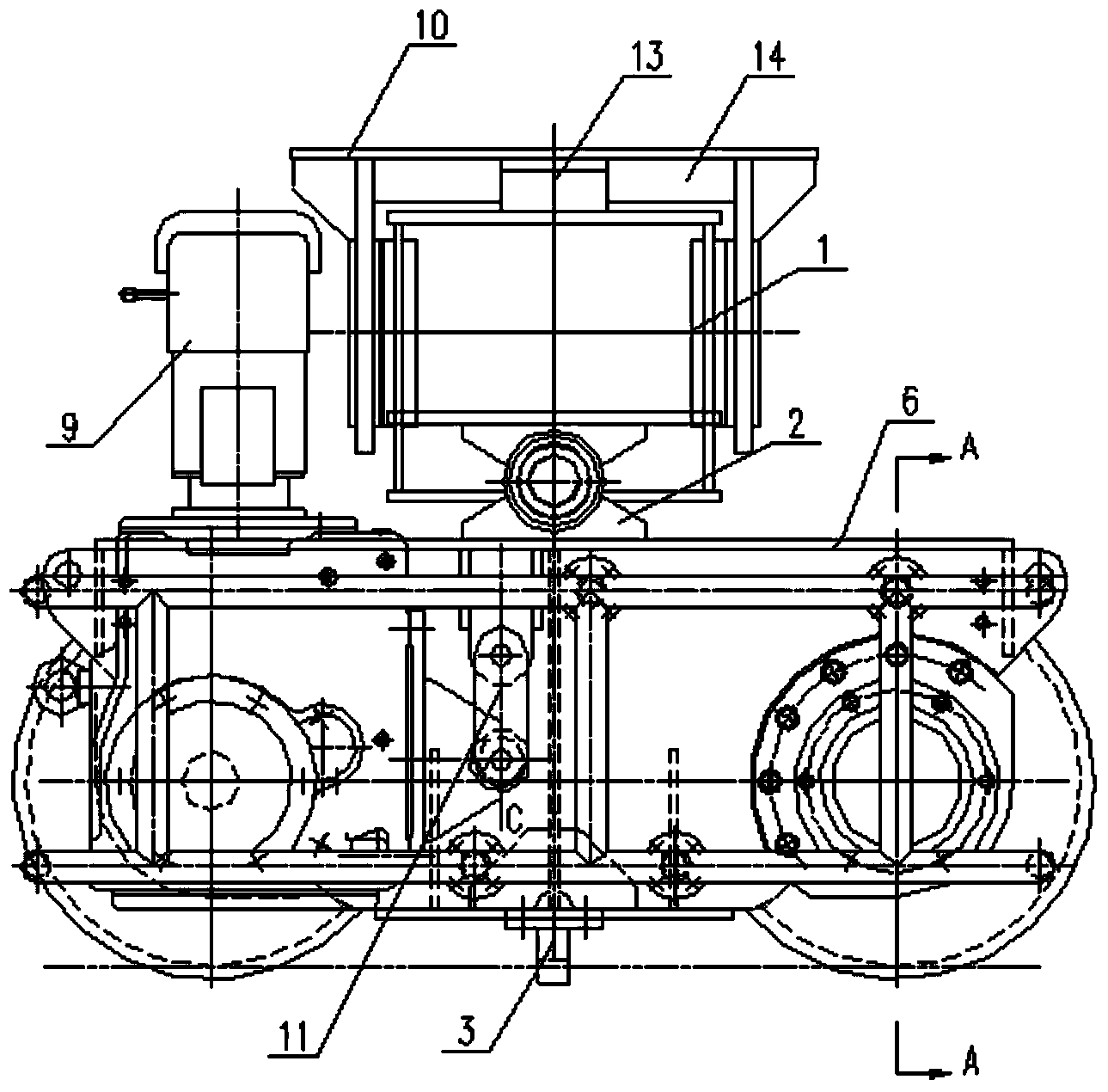

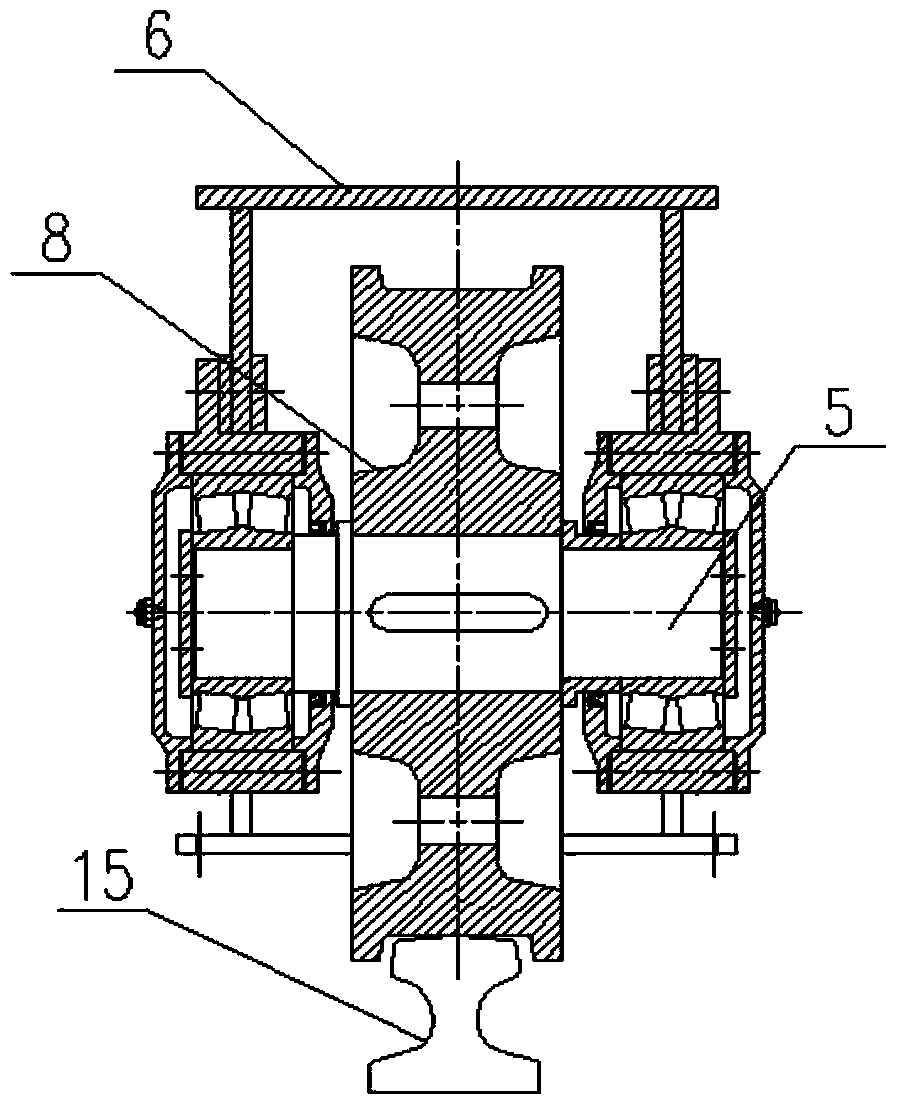

[0023] A cart traveling trolley with a broken shaft protection device of the present invention includes a balance beam 1, a half hinge 2, a trolley frame 6, a driving motor 9, a driving motor bracket 11, a motor protection frame 12, and a drive shaft 4 , Passive shaft 5, broken shaft protection device 3, driving wheel 7, passive wheel 8, hinge support 10, block I13, block II14, track 15.

[0024] like Figures 1 to 4 As shown, there is a reaming hole in the middle part of the balance beam 1, which is hinged with the corresponding hinge support 10 through a shaft, the stopper II14 is welded on the hinge support 10, the stopper I13 is welded on the balance beam 1, and the two ends of the balance beam 1 are connected to the The trolley frames 6 are connected by the Huff hinge 2 to form a double-track trolley. The axis direction of the Huff reaming hole is perpendicular to the axis direction of the middle reaming hole of the balance beam. The driving motor 9 is connected to the dr...

Embodiment 2

[0029] A cart traveling trolley with a broken shaft protection device of the present invention includes a balance beam 1, a half hinge 2, a trolley frame 6, a driving motor 9, a driving motor bracket 11, a motor protection frame 12, and a drive shaft 4 , Passive shaft 5, broken shaft protection device 3, driving wheel 7, passive wheel 8, hinge support 10, block I13, block II14, track 15.

[0030] like Figures 1 to 4 As shown, there is a reaming hole in the middle part of the balance beam 1, which is hinged with the corresponding hinge support 10 through a shaft, the stopper II14 is welded on the hinge support 10, the stopper I13 is welded on the balance beam 1, and the two ends of the balance beam 1 are connected to the The trolley frames 6 are connected by the Huff hinge 2 to form a double-track trolley. The axis direction of the Huff reaming hole is perpendicular to the axis direction of the middle reaming hole of the balance beam. The driving motor 9 is connected to the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com