Circular shielding insulating bus and machining method thereof

A technology of shielding insulation and bus bar, applied in the direction of insulating cables, insulating conductors, conductor/cable insulation, etc., can solve the problems of bringing in impurities, reducing the electrical insulation performance of the pipe mother, and the impossibility of matching humidity and temperature. The effects of increasing distance, improving power supply efficiency, excellent electrical performance and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

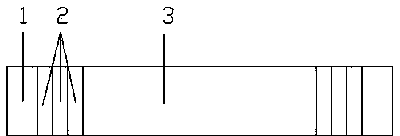

[0037] As shown in the figure, a 10KV circular shielded insulated bus bar includes a circular conductor 1 and an outer sheath 2. A circular channel 4 is provided in the circular conductor 1. The surface of the conductor is tightly wrapped with a layer of insulating shielding layer 3, where the insulating shielding layer 3 is composed of an insulating layer 31 and a shielding layer 32. The insulating layer 31 includes two layers of PTFE 311 and a heat shrinkable sheath 312 from the inside to the outside. Silicone oil is evenly coated between the tetrafluoroethylene 311 and the heat shrinkable sheath 312. After that, leave 5cm at both ends of each insulating shielding layer 3 to make the second, third, and fourth insulating shielding layers. Use polyolefin polymer as the outer protective layer outside the fourth insulating shielding layer. Cover 2, and ground the braided copper mesh 5 around the fourth insulating shielding layer.

[0038] The production method is as follows:

[003...

example 2

[0044] As shown in the figure, a 35KV circular shielded insulated bus bar includes a circular conductor 1 and an outer sheath 2. A circular channel 4 is provided in the circular conductor 1. The surface of the conductor is tightly wrapped with a layer of insulating shielding layer 3, where the insulating shielding layer 3 is composed of an insulating layer 31 and a shielding layer 32. The insulating layer 31 includes two layers of PTFE 311 and a heat shrinkable sheath 312 from the inside to the outside. Silicone oil is evenly coated between the tetrafluoroethylene 311 and the heat shrinkable sheath 312. After that, leave 5cm at both ends of each insulating shielding layer 3 to make the second, third, fourth, fifth, sixth, seventh, and eighth insulating shielding layer, outside of the eighth insulating shielding layer The outer sheath 2 is made of polyolefin polymer, and the eighth insulating shielding layer is wrapped around the braided copper mesh 5 for grounding.

[0045] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com