Adjusting mechanism of diaphragm plate of alignment system

A technology for adjusting mechanisms and aligning systems, applied in optics, microlithography exposure equipment, and photoplate-making processes on patterned surfaces, etc., can solve problems such as poor processing technology, inconvenient operation, and increased difficulty, and achieve simplification structure, improving convenience and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

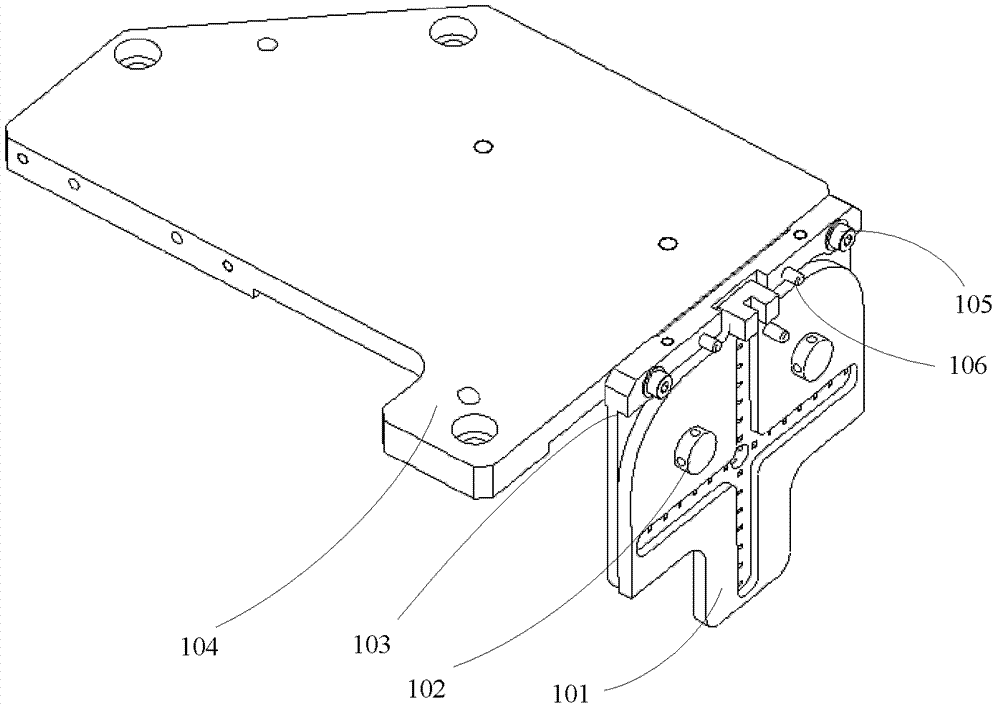

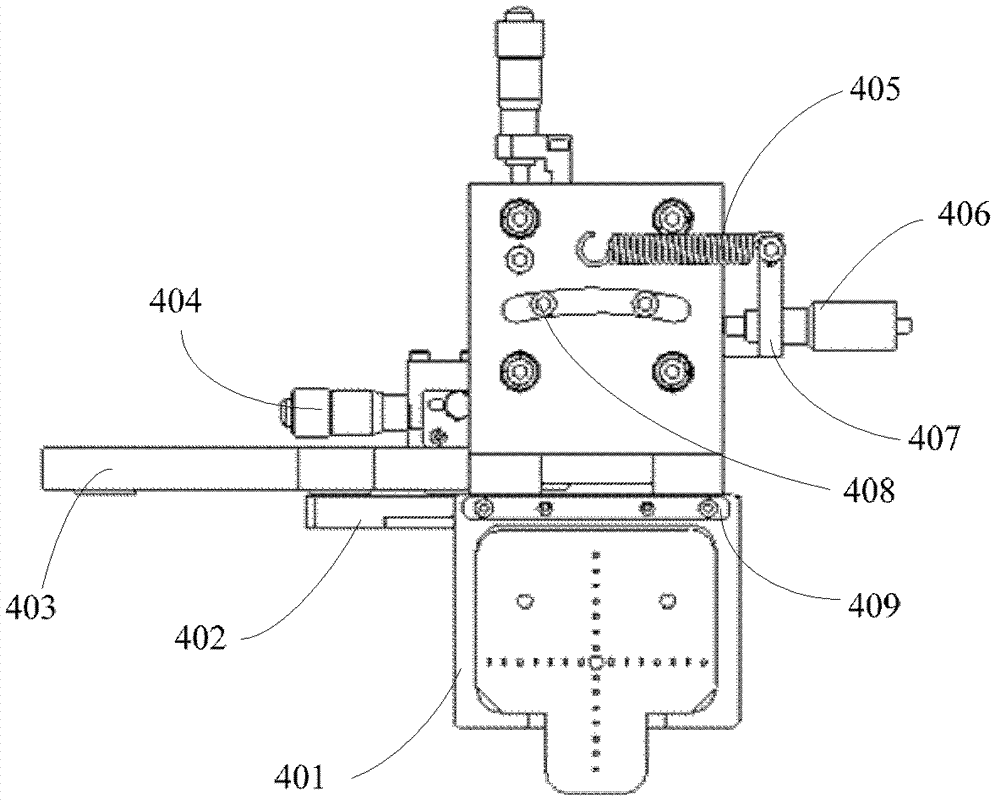

[0025] Please refer to image 3 and Figure 4 , image 3 and Figure 4 Shown is a schematic structural diagram of the adjustment mechanism of the aperture plate of the alignment system in a preferred embodiment of the present invention. The present invention proposes an adjustment mechanism for the aperture plate of the alignment system, which includes: an operating machine housing; an aperture plate fixing plate 402 fixed on the operating machine housing; a sliding table fixing plate 403 fixed on the The XY slide table 404 is fixed on the slide table fixing plate 403, the slide table connecting plate 410 is installed on the XY slide table 404, and the XY slide table 404 has a knob to control the slide table. The table connecting plate 410 moves independently in the X and Y directions relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com