Pipe connectors with compensators

A connector and compensator technology, applied in the direction of pipe joints, pipes/pipe joints/pipe fittings, expansion compensation devices for pipelines, etc., can solve problems such as insufficient, insufficient cleaning, and misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

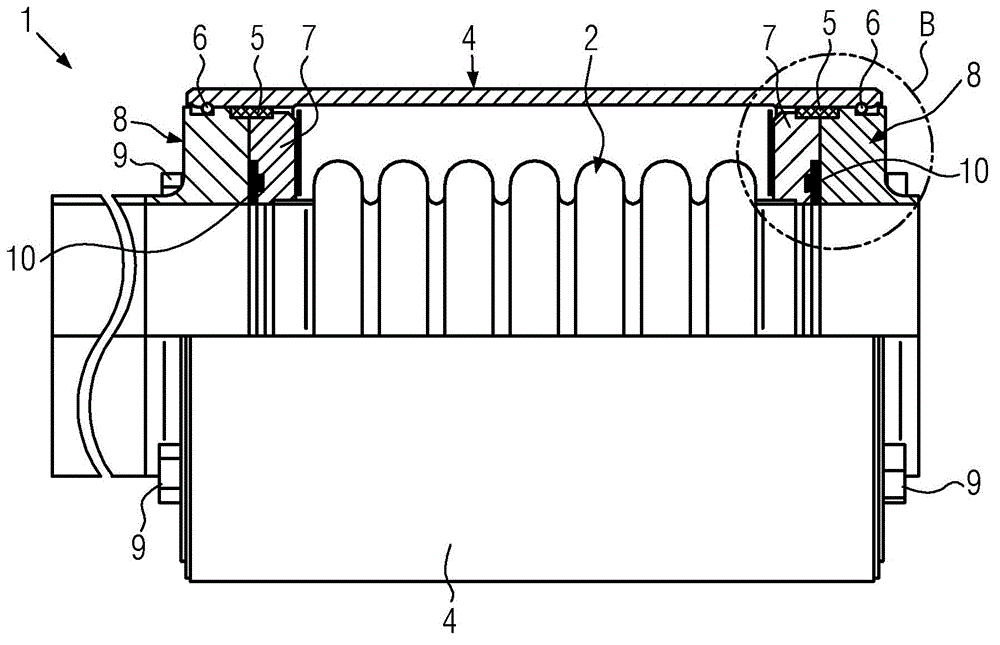

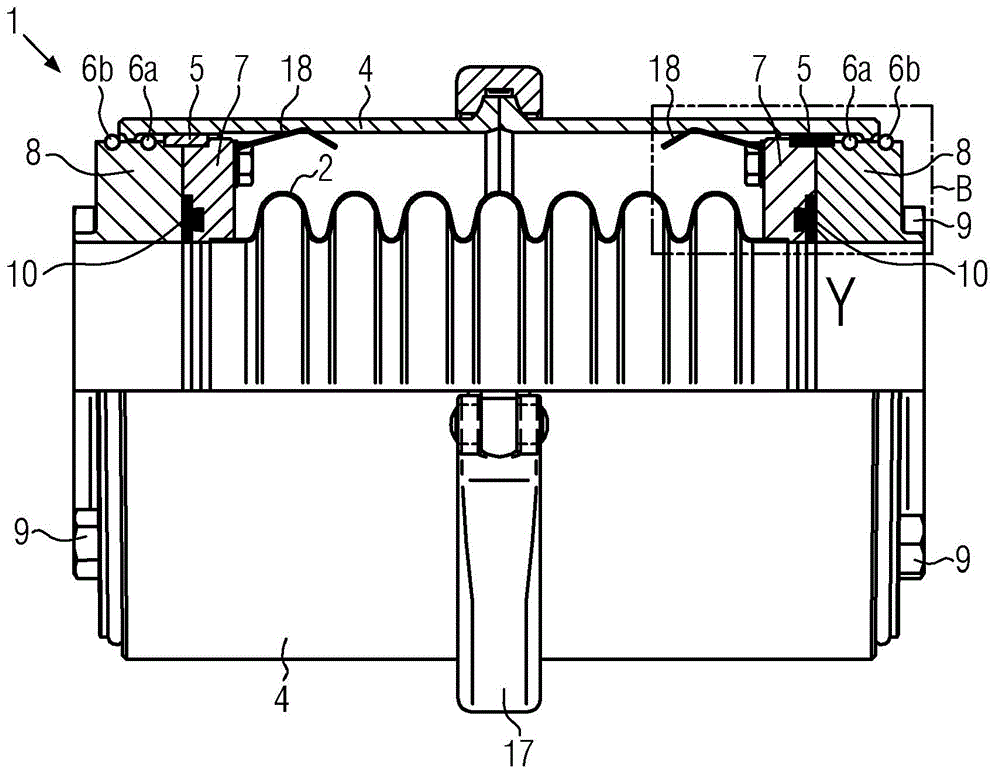

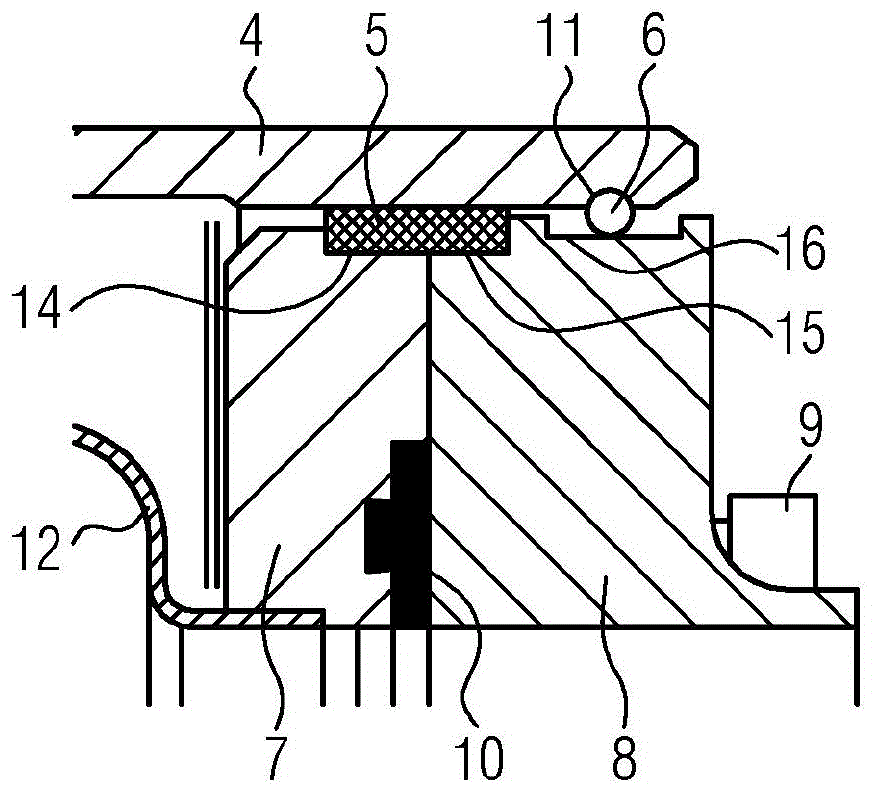

[0048] Figure 1a Shown is a pipe connector 1 comprising a compensator 2, a mounting aid 6 and means for centering the compensator. exist Figure 1a In the example shown in , the components used for centering include a centering sleeve 4 and a guide strip 5 .

[0049] exist Figure 1a In the lower half of the figure shown in , the (installed) centering sleeve can be seen from the outside; in the upper half, a section through the axis of the pipe connector can be seen.

[0050] Furthermore, the pipe connector may comprise flanges 7 at both ends of the compensator. The pipe connector may also be connected to two pipes by means of a flange 8 and may optionally comprise a flange 8 . For example, the pipe connector can be detachably mounted to the pipe by screwing the flange connections together with bolts 9 . As shown in FIG. 1 , the compensator may also comprise a seal 10 which, in the installed state, acts as a seal and prevents fluid or conveyed food from escaping from the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com