Installation method of prefabricated platform

An installation method and a technology of prefabricated caps, which are applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve problems such as long construction period, and achieve the effects of reducing construction costs, improving stability, and small surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

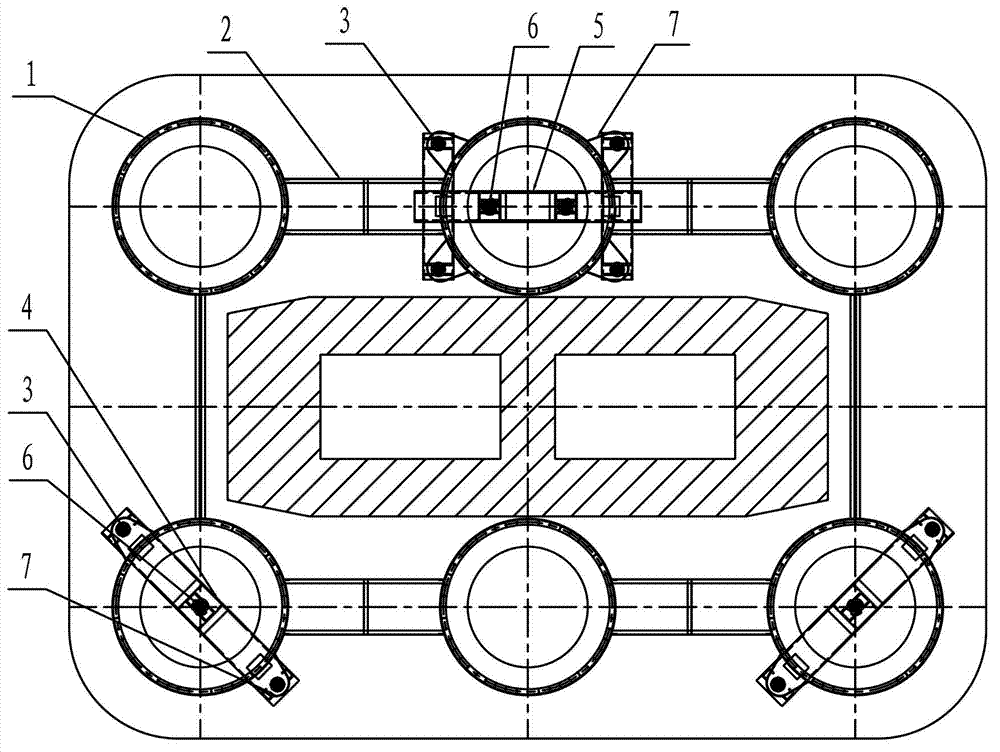

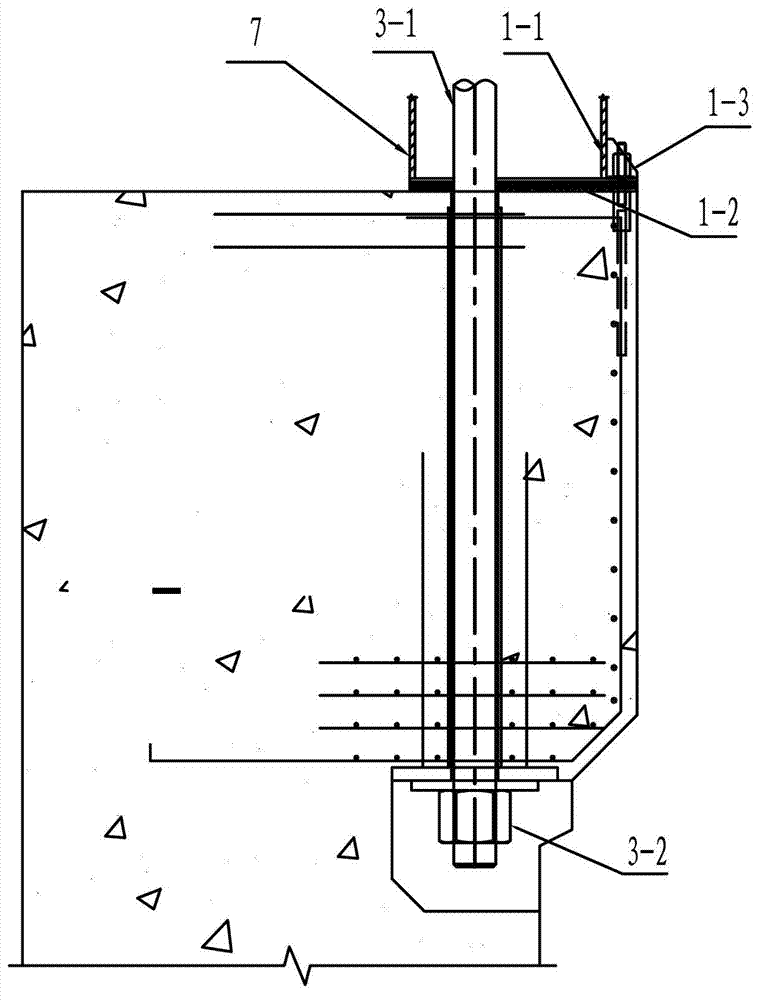

[0027] see figure 1 , 2 As shown, the embodiment of the present invention provides a method for installing a prefabricated platform, including the following steps:

[0028] A. Complete the prefabrication of caps and bottom pier bodies in the prefabrication plant, reserve holes for pile foundations, steel bar joints, reserved holes for steel rods and pre-buried bolts for fixing steel cylinder cofferdam 1, and wait for the caps to reach the design strength Afterwards, install the steel cylinder cofferdam 1, the steel rod 3 for hoisting the cap, the first pole for hanging piles 4 and the second pole for hanging piles 5, and a steel cylinder cofferdam 1 is set at each pile foundation reserved hole, each Steel cylinder cofferdams 1 are connected by connecting systems to enhance their overall stability; see image 3 As shown, the steel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com