A method for depositing thick aluminum-copper film layers

A thin-film, aluminum-copper technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of reducing the service life of semiconductor equipment, temperature rise, wafer temperature rise, etc., to avoid temperature The effect of increasing, reducing whisker-like defects and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

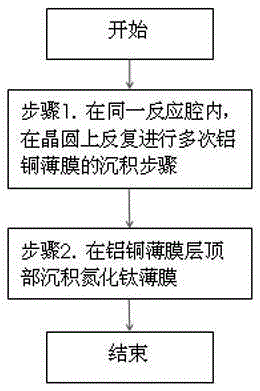

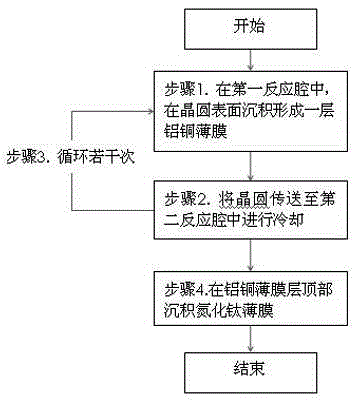

[0039] In the first embodiment, it is necessary to deposit an aluminum-copper thin film layer with a thickness of 40K on the wafer, and the specific operation steps are as follows:

[0040] Step 1. In the first PVD reaction chamber, a first layer of aluminum-copper film with a thickness of 8000 Å is deposited on the surface of the wafer by PVD method;

[0041] Step 2, transferring the wafer deposited with the first layer of Al-Cu thin film to the second PVD reaction chamber, and cooling at room temperature for 20 seconds;

[0042] Step 3. Transfer the cooled wafer to the first PVD reaction chamber again, and continue to perform the deposition process and cooling process 4 times (that is, a total of 5 cycles), and deposit the second layer to the first layer on the wafer in turn. Five-layer aluminum-copper film, and after completing the deposition step of a layer of 8000 ? Aluminum-copper film layer;

[0043] Step 4, depositing a TiN film on top of the 40K?Al-Cu film layer.

Embodiment 2

[0045] In the second embodiment, it is necessary to deposit an aluminum-copper thin film layer with a thickness of 36K on the wafer, and the specific operation steps are as follows:

[0046] Step 1. In the first PVD reaction chamber, a first layer of aluminum-copper film with a thickness of 6000 Å is deposited on the surface of the wafer by PVD method;

[0047] Step 2, transfer the wafer on which the first layer of Al-Cu film has been deposited to the second PVD reaction chamber, and cool it at 30° C. for 15 seconds;

[0048]Step 3. Retransmit the cooled wafer to the first PVD reaction chamber, and continue to cycle through the deposition process and cooling process for 5 times (that is, a total of 6 cycles), and deposit the second layer to the first layer on the wafer in turn. Six-layer aluminum-copper film, and after each deposition of a layer of 6000? ?Aluminum-copper film layer;

[0049] Step 4, depositing a TiN film on top of the 36K?Al-Cu film layer.

Embodiment 3

[0051] In the third embodiment, it is necessary to deposit an aluminum-copper thin film layer with a thickness of 20K on the wafer, and the specific operation steps are as follows:

[0052] Step 1. In the first PVD reaction chamber, a first layer of aluminum-copper film with a thickness of 4000 Å is deposited on the surface of the wafer by PVD method;

[0053] Step 2, transfer the wafer on which the first layer of Al-Cu film has been deposited to the second PVD reaction chamber, and cool it at 40° C. for 12 seconds;

[0054] Step 3. Transfer the cooled wafer to the first PVD reaction chamber again, and continue to perform the deposition process and cooling process 4 times (that is, a total of 5 cycles), and deposit the second layer to the first layer on the wafer in turn. Five-layer aluminum-copper film, and after each deposition step of a 4000? ?Aluminum-copper film layer;

[0055] Step 4, depositing a TiN film on top of the 32K?Al-Cu film layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com