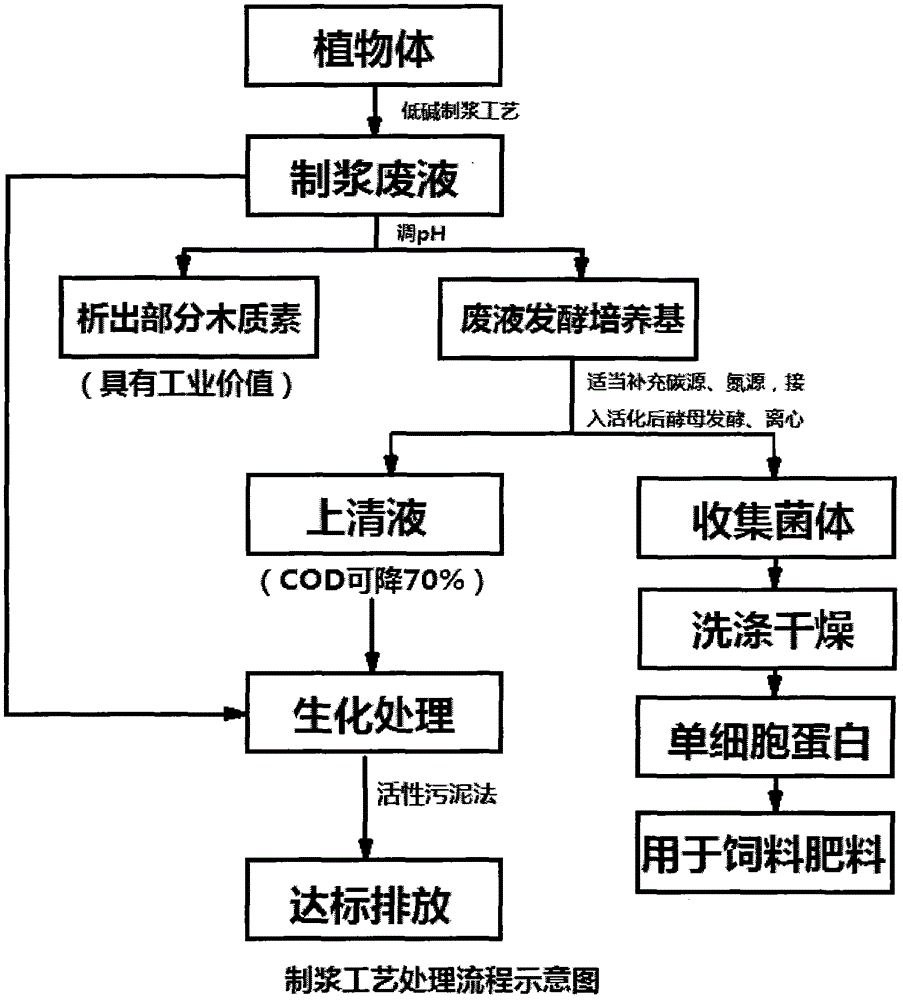

A method for producing single-cell protein from pulping waste liquid

A single-cell protein and pulping waste liquid technology, applied in the field of single-cell protein production, can solve the problems of high energy consumption, large equipment investment, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

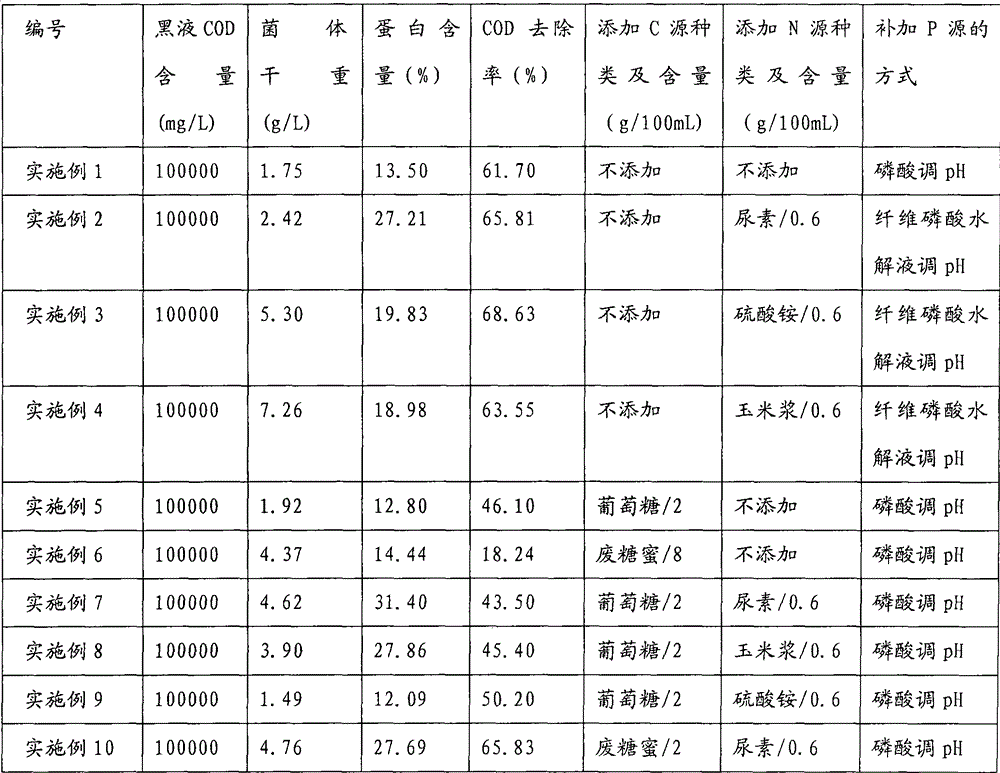

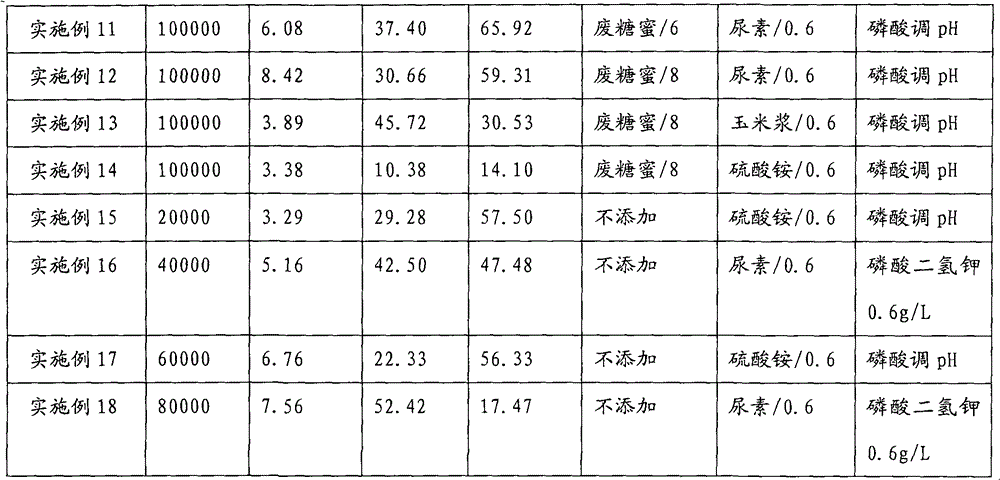

Examples

Embodiment 1

[0018]Phosphoric acid was used to adjust the pH of the slurry waste liquid to 5.5, and the precipitated lignin was removed after centrifugation at 4000r / min for 10 minutes, and 100ml of the supernatant was put into a 250ml Erlenmeyer flask without adding any other nutrients, and sterilized at 115°C for 30 minutes. After the fermentation medium was cooled to room temperature, the seed culture solution of Candida utilis CICC3.144 was added, and the amount of the yeast seed culture solution added was 10% of the volume of the papermaking waste liquid medium. Cultivate at 33°C on a shaker at 180rpm / min for 40h. After fermentation, the liquid is centrifuged and washed to collect the bacteria, and dried in a vacuum oven at 60°C to obtain the product. After 24 hours, it can be dried to constant weight.

Embodiment 2

[0020] The difference between this embodiment and Embodiment 1 is that the phosphoric acid hydrolyzate of straw powder is used to adjust the pH of the slurry waste liquid to 5.5, and 0.6 g of urea is added to the fermentation medium of the waste liquid for lignin removal, and the other operation steps are exactly the same.

Embodiment 3

[0022] The difference between this embodiment and the specific embodiment 1 is that the phosphoric acid hydrolyzate of straw powder is used to adjust the pH of the slurry waste liquid to 5.5, and 0.6 g of ammonium sulfate is added to the fermentation medium of the waste liquid for lignin removal, and the other operation steps are exactly the same .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com