Method for separating and purifying chenodeoxycholic acid from goose bile

A technology of chenodeoxycholic acid and chenodeoxycholic acid, applied in the directions of steroids, organic chemistry, etc., can solve the problems of expanding chenodeoxycholic acid, etc., and achieve the effect of strong repeatability, high repeatability and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of crude chenodeoxycholic acid from goose bile

[0023] Take goose bile 200g (volume is 200mL) and put it in a beaker, add 6% sodium chloride solid by weight of bile, heat at 90°C for 10h for saponification, add calcium chloride solid of 8% by weight of bile after cooling to obtain precipitation, Collect the precipitate by centrifugation, dissolve the precipitate with distilled water 3 times the volume of the precipitate, stir for 50 minutes and collect the supernatant by centrifugation, adjust the pH to 3.0 with hydrochloric acid to obtain the precipitate, collect the precipitate by centrifugation, and dry the precipitate to obtain a khaki goose Oxycholic acid solid 5.32g.

Embodiment 2

[0025] Preparation of crude chenodeoxycholic acid from goose bile

[0026] Take goose bile 500g (volume is 500mL) and place in a beaker, add 8% sodium chloride solid by weight of bile, heat at 95°C for 15h for saponification, add 10% calcium chloride solid by weight of bile after cooling to obtain precipitation, Collect the precipitate by centrifugation, dissolve the precipitate with distilled water 3 times the volume of the precipitate, stir for 60 minutes and collect the supernatant by centrifugation, adjust the pH to 4.0 with hydrochloric acid to obtain the precipitate, collect the precipitate by centrifugal separation, and obtain the earthy yellow goose after the precipitate is dried Oxycholic acid solid 12.03g.

Embodiment 3

[0028] Purification of chenodeoxycholic acid

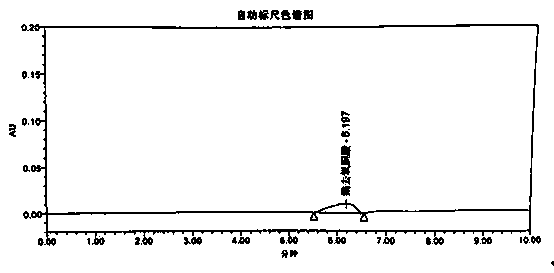

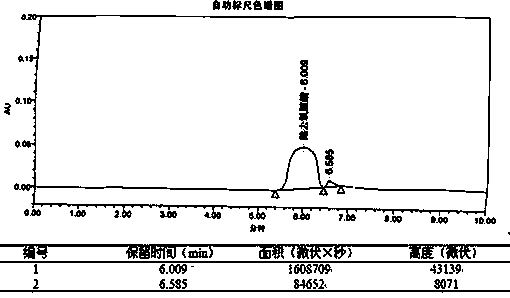

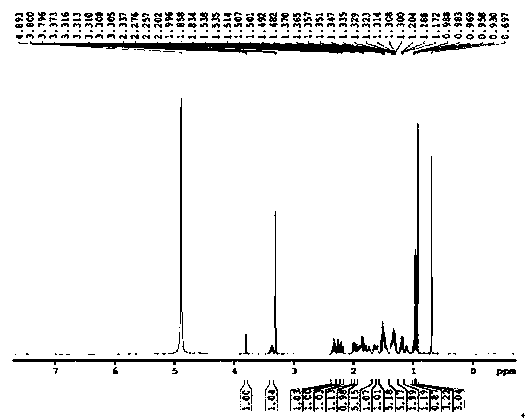

[0029] Take the crude chenodeoxycholic acid obtained in Example 1 or 2 and sodium hydroxide at a ratio of 1:1 and heat and dissolve in 25 times of water to form a chenodeoxycholic acid extract, and inject the extract into a 711-type macropore In the resin chromatography column, use 40% ethanol solution to elute until the effluent is colorless and transparent, then use 5% sodium hydroxide solution 4 times the weight of the extract to elute, collect the eluent, and use hydrochloric acid as the eluent Adjust the pH to 3.0, centrifuge to obtain chenodeoxycholic acid, dry, the yield of chenodeoxycholic acid is 1.32%, and the purity is 95% (see figure 1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com