Method for recrystallizing ubenimex

A technology of ubenimex and ubenimex hydrochloride, which is applied in the field of medicine and can solve problems such as production failure, agitator failure, and yield reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

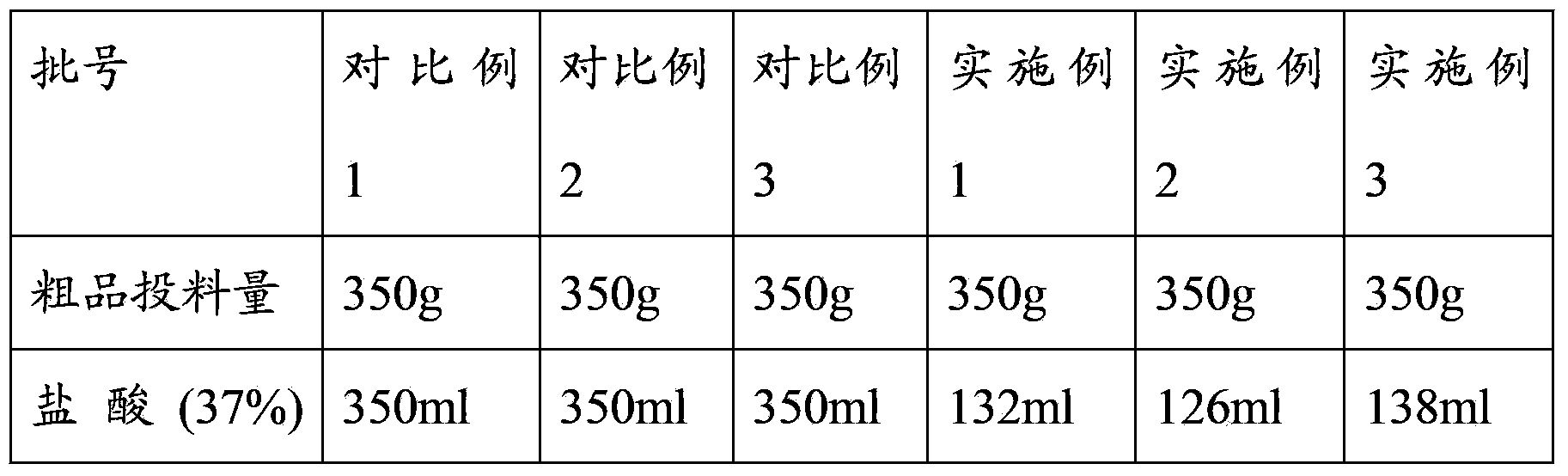

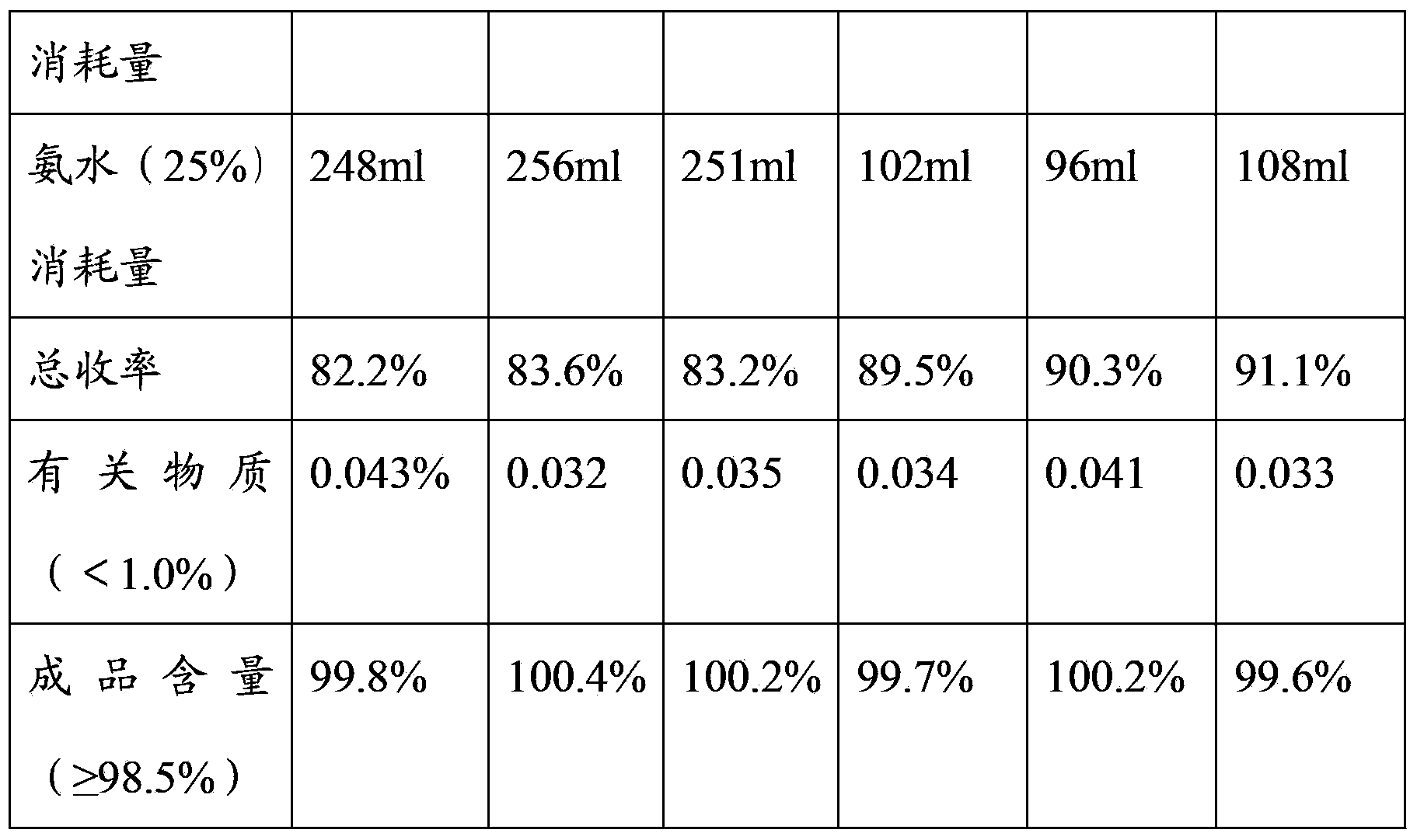

Embodiment 1

[0011] Add 1000ml of purified water into the three-necked flask, start stirring, add 350g of crude ubenimex, heat to 60±2°C, add hydrochloric acid (18.5%) dropwise until the crude product dissolves, filter to obtain ubenimex hydrochloric acid solution.

[0012] Take another three-neck flask and add 2000ml of purified water, start stirring, control the temperature of the system at about 0°C in an ice-water bath, and add ubenimex hydrochloric acid solution and ammonia water (4%) dropwise at the same time, control the dropping speed of the two solutions, and make the reaction system The pH is maintained around 3-4. After the acid solution is added dropwise, use ammonia water (1%) to fine-tune the pH=5-6, and filter after 24 hours of crystallization.

[0013] The filter cake was washed with a small amount of purified water, filtered with suction until there was no water drop, and dried under reduced pressure at 40°C to constant weight. The purity of the product was tested to be 99...

Embodiment 2

[0015] Add 1000ml of purified water into a three-neck flask, start stirring, add 350g of crude ubenimex, heat to 60±2°C, add hydrochloric acid (18.5%) dropwise until the crude product dissolves, filter to obtain ubenimex hydrochloric acid solution.

[0016] Take another three-neck flask and add 2000ml of purified water, start stirring, and control the temperature of the system at about 2°C in an ice-water bath. The pH is maintained around 4-5. After the acid solution is added dropwise, use ammonia water (1%) to fine-tune the pH=5-6, and filter after 24 hours of crystallization.

[0017] The filter cake was washed with a small amount of purified water, filtered with suction until there was no water drop, and dried under reduced pressure at 40°C to constant weight. The purity of the product was tested to be 100.2%, and the total yield was 90.3%.

Embodiment 3

[0019] Add 1000ml of purified water into the three-necked flask, start stirring, add 350g of crude ubenimex, heat to 60±2°C, add hydrochloric acid (18.5%) dropwise until the crude product dissolves, filter to obtain ubenimex hydrochloric acid solution.

[0020] Take another three-neck flask and add 2000ml of purified water, start stirring, and control the temperature of the system at about 3°C in an ice-water bath. The pH is maintained around 3-4. After the acid solution is added dropwise, use ammonia water (1%) to fine-tune the pH=5-6, and filter after 24 hours of crystallization.

[0021] The filter cake was washed with a small amount of purified water, filtered with suction until there was no water drop, and dried under reduced pressure at 40°C to constant weight. The purity of the product was tested to be 99.6%, and the total yield was 91.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com