Preparation method of kaolin-amine grafted complex

A kaolin and compound technology, applied in silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as single intercalation agent, limited types of kaolin, and unfavorable research and development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

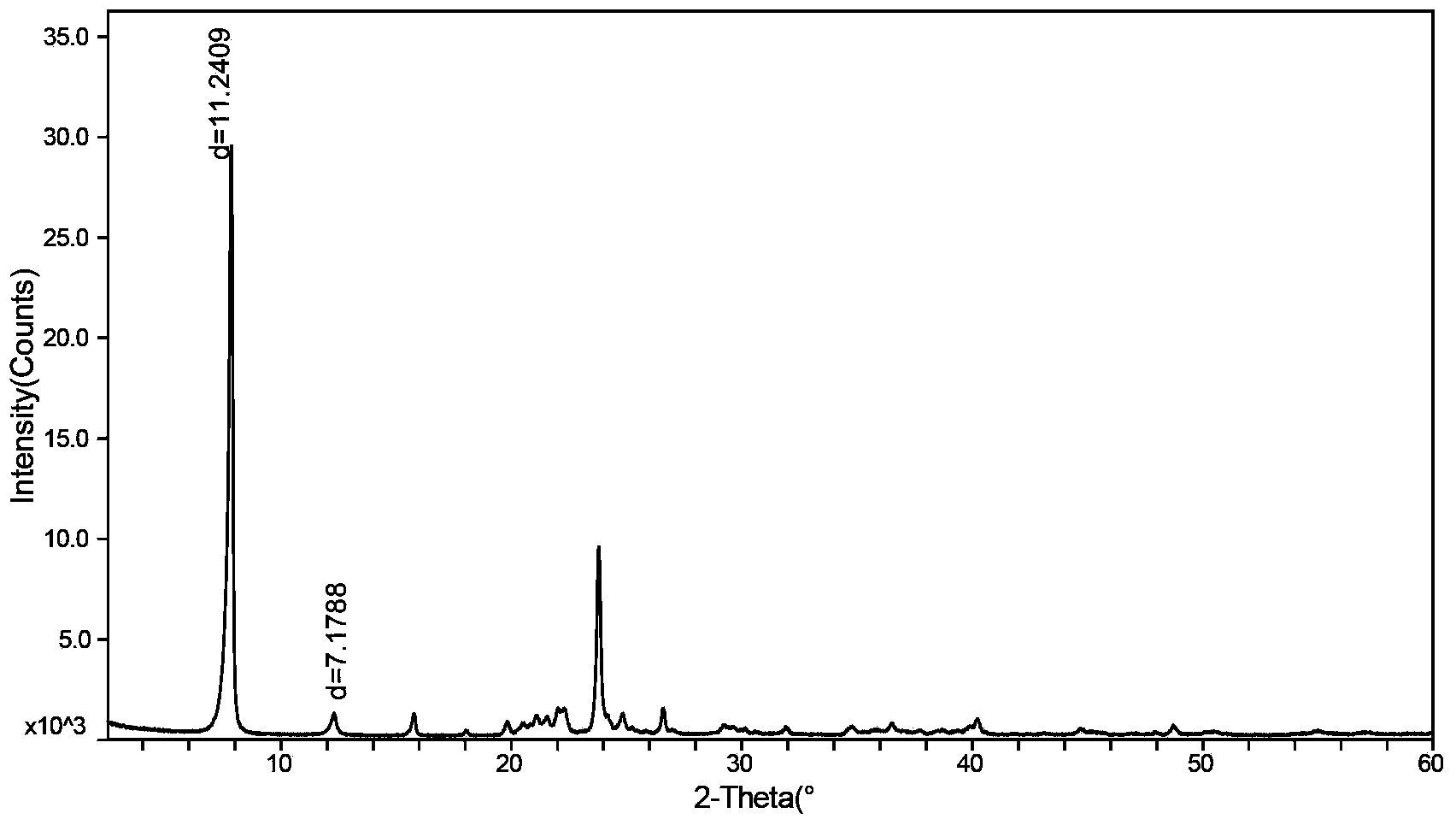

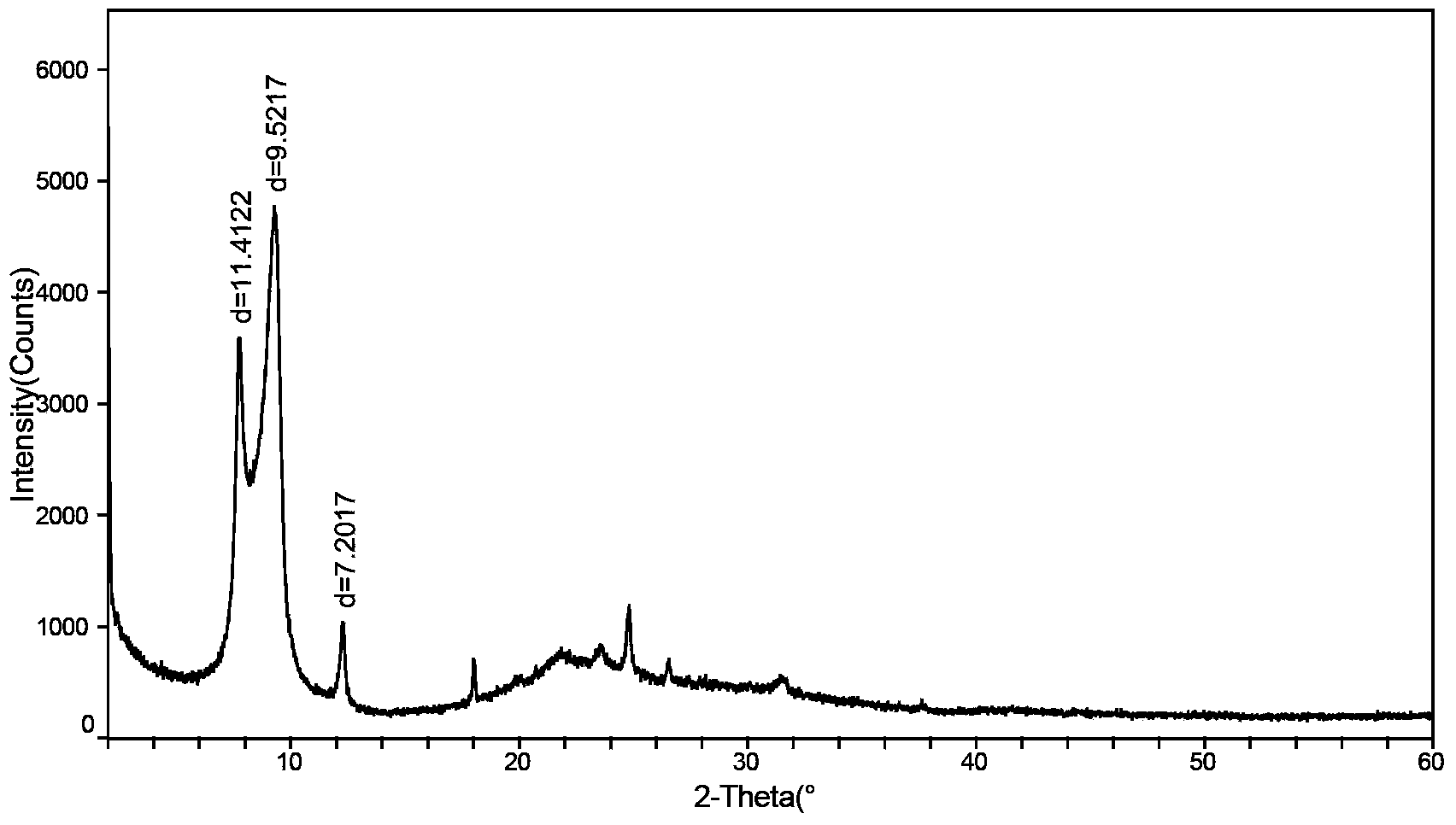

[0025] Get 50g of 325 mesh white soft kaolin, its XRD pattern is shown in the attached figure 1 .Add 100ml of intercalation agent solution according to the mass ratio of 1:2. This solution is prepared from dimethyl sulfoxide and water according to the ratio of 9:1. The slurry was reacted at 60°C for 24 hours, and the precipitate obtained by centrifugation was dried at 60°C for 1 day to obtain a kaolin-dimethylsulfoxide intercalation complex with an intercalation rate of 96%. Its XRD pattern is attached figure 2 . Add 5 g of kaolin-dimethyl sulfoxide complex to 100 ml of methanol, stir magnetically at room temperature for 24 hours, centrifuge to separate the precipitate and add new methanol, repeat this 8 times, and obtain the kaolin-methanol complex, its XRD pattern See attached image 3 . After the kaolin-methanol complex was dried at room temperature, n-hexylamine was added and reacted at room temperature for one day. After centrifugation, the precipitate obtained is t...

Embodiment 2

[0027] Get 50g of 325 mesh white soft kaolin, its XRD pattern is shown in the attached figure 1 .Add 150ml of saturated urea solution, react at 60°C for 24 hours, centrifuge to obtain the precipitate and dry at 60°C for 2 days to obtain a kaolin-urea intercalation complex with an intercalation rate of 80%. Its XRD pattern is attached Figure 5 . Add 4 g of kaolin-urea intercalation complex to 100 ml of methanol, stir magnetically at room temperature for 24 hours, centrifuge to separate the precipitate and add new methanol, repeat this 8 times, and obtain the kaolin-methanol complex. See the attached XRD pattern. Figure 6. After the kaolin-methanol complex was dried at room temperature, 40 ml of n-hexylamine was added and reacted at room temperature for one day. Centrifuge, get the precipitate and continue to add 50ml dodecylamine, react at 40°C for 30 hours, centrifuge the precipitate and dry it at 40°C, the precipitate will spontaneously precipitate excess amine, that is,...

Embodiment 3

[0029] Take 20g of 325 mesh white soft kaolin, add 150ml of methylformamide solution (the ratio of methylformamide to water is about 8:1), react at room temperature for 30 hours, centrifuge to obtain the precipitate and dry it at 60°C for 2 days to get A kaolin-methylformamide intercalation composite with an intercalation rate of 75%. Add 5 g of kaolin-methylformamide intercalation complex to 100 ml of methanol, stir magnetically at room temperature for 24 hours, centrifuge to separate the precipitate and add new methanol, and repeat this 6 times to obtain kaolin-methanol complex. Dodecylamine was added to the kaolin-methanol complex, and magnetically stirred at 40°C for 24 hours. After centrifugation, the precipitate obtained is the kaolin-laurylamine grafting complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com