Plant essence-containing sunscreen foundation cream

An isolating powder and essence technology, applied in the field of foundation cream, can solve the problems of clogged pores, no isolated skin with makeup, no benefit to the skin, etc., to prevent photoaging, protect against ultraviolet rays and environmental damage, and smooth the effects of age marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

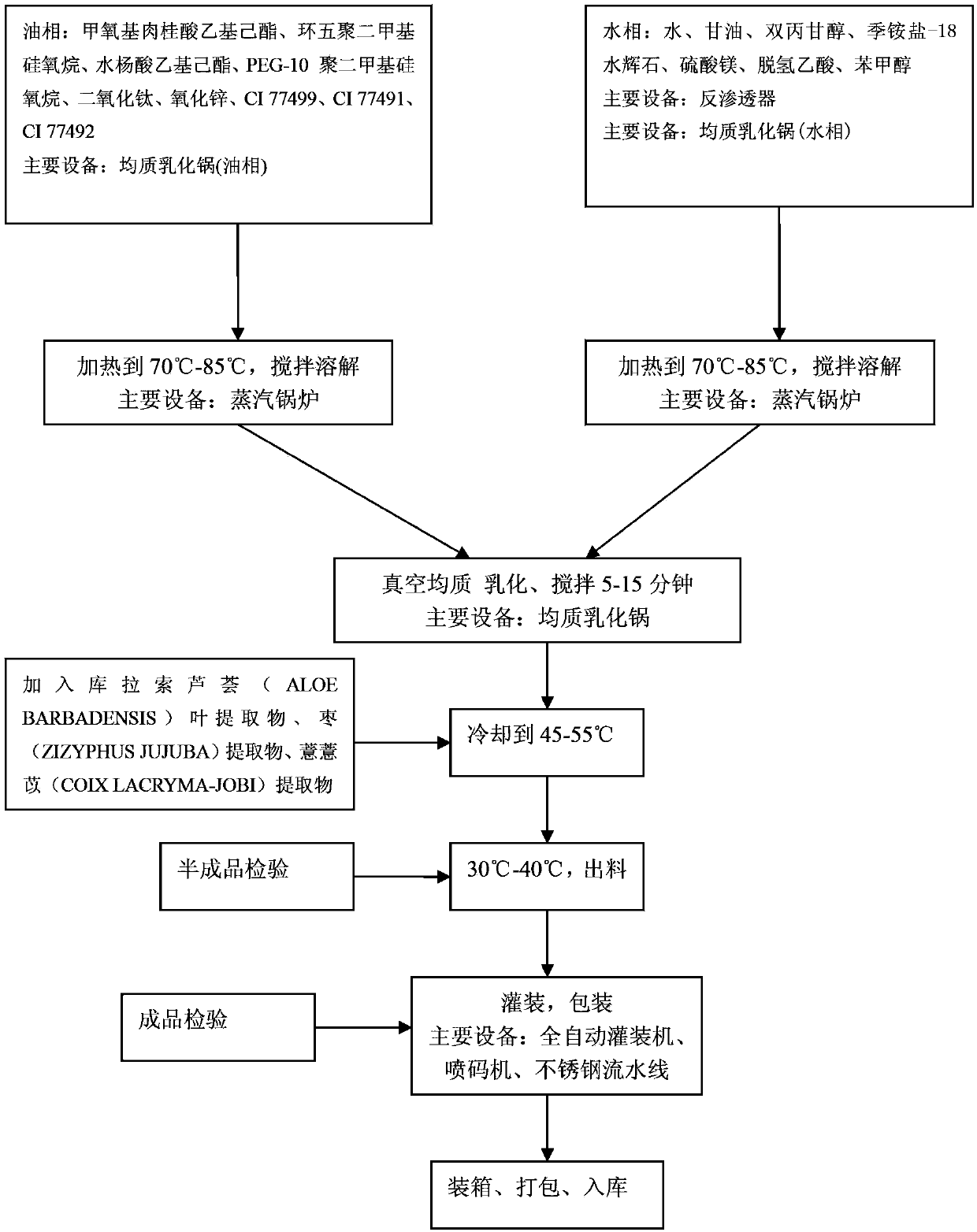

[0021] The preparation method of plant essence whitening and spot-removing cream of the present invention comprises the following steps:

[0022] 1. Heat the oil phase material in the oil phase pot of the homogeneous emulsification pot to 70°C-85°C, stir and dissolve; the oil phase material includes 7.5-9 parts by mass of ethylhexyl methoxycinnamate, 15 -20 parts by mass of cyclopentasiloxane, 4-5 parts by mass of ethylhexyl salicylate, 2.5-3.5 parts by mass of PEG-10 polydimethylsiloxane, 5-9 parts by mass parts by mass of titanium dioxide, 3-7 parts by mass of zinc oxide, 0.07-0.09 parts by mass of iron oxide red, 0.05-0.07 parts by mass of iron oxide yellow and 0.02-0.05 parts by mass of iron oxide black.

[0023] 2. Heat the water phase material in the water phase pot of the homogeneous emulsification pot to 70°C-85°C, stir and dissolve; the water phase material includes 35-44 parts by mass of water, 4-6 parts by mass of glycerin, 3- 6 parts by mass of dipropylene gly...

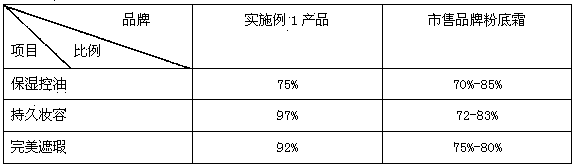

Embodiment 1

[0030] 1. Oil phase material [ethylhexyl methoxycinnamate, cyclopentasiloxane, ethylhexyl salicylate, PEG-10 polydimethylsiloxane, titanium dioxide, zinc oxide , iron oxide black, iron oxide red, iron oxide yellow]] in the oil phase pot of the homogeneous emulsification pot, heated to 70°C, stirred and dissolved. Wherein the ratio of each component is: 7.5%, 17%, 5%, 3%, 7%, 5%, 0.03%, 0.08%, 0.06%.

[0031] 2. Heat the water phase material [water, glycerin, dipropylene glycol, quaternary ammonium-18 hectorite, magnesium sulfate, dehydroacetic acid, benzyl alcohol] in the water phase pot of the homogeneous emulsification pot to 70 ° C, stir dissolve. Wherein the ratio of each component is: 40.78%, 5%, 4%, 1%, 0.8%, 0.05%, 0.7%.

[0032] 3. Under stirring, slowly pump the oil phase material into the water phase, and emulsify in vacuum for 5 minutes.

[0033] 4. Turn on the cooling water under slow stirring, cool the paste to 45°C, add [Aloe Barbadensis Leaf Extract, ZIZY...

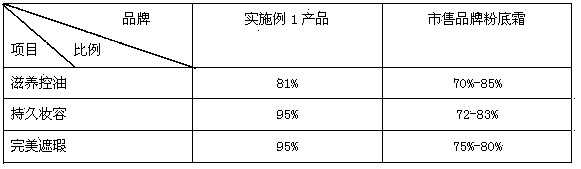

Embodiment 2

[0038] 1. Oil phase material [ethylhexyl methoxycinnamate, cyclopentasiloxane, ethylhexyl salicylate, PEG-10 polydimethylsiloxane, titanium dioxide, zinc oxide , iron oxide black, iron oxide red, iron oxide yellow]] in the oil phase pot of the homogeneous emulsification pot, heated to 77 ° C, stirred and dissolved. Wherein the proportion of each component is: 8%, 15%, 4.5%, 3.5%, 9%, 7%, 0.05%, 0.09%, 0.07%.

[0039] 2. Heat the water phase material [water, glycerin, dipropylene glycol, quaternary ammonium-18 hectorite, magnesium sulfate, dehydroacetic acid, benzyl alcohol] to 77°C in the water phase pot of the homogeneous emulsification pot, and stir dissolve. Wherein the ratio of each component is: 35%, 6%, 6%, 1.2%, 0.7%, 0.04%, 0.85%.

[0040] 3. Under stirring, slowly pump the oil phase material into the water phase, and emulsify in vacuum for 10 minutes.

[0041] 4. Turn on the cooling water under slow stirring, cool the paste to 50°C, add [Aloe Barbadensis Leaf Extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com