Chemical looping combustion method capable of inhibiting oxygen carrier sintering and reducing heat loss

A technology of chemical chain combustion and oxygen carrier, which is applied in combustion methods, fuels burned in a molten state, fluidized bed combustion equipment, etc. The problem is to reduce the heat loss of exhaust smoke and inhibit surface sintering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

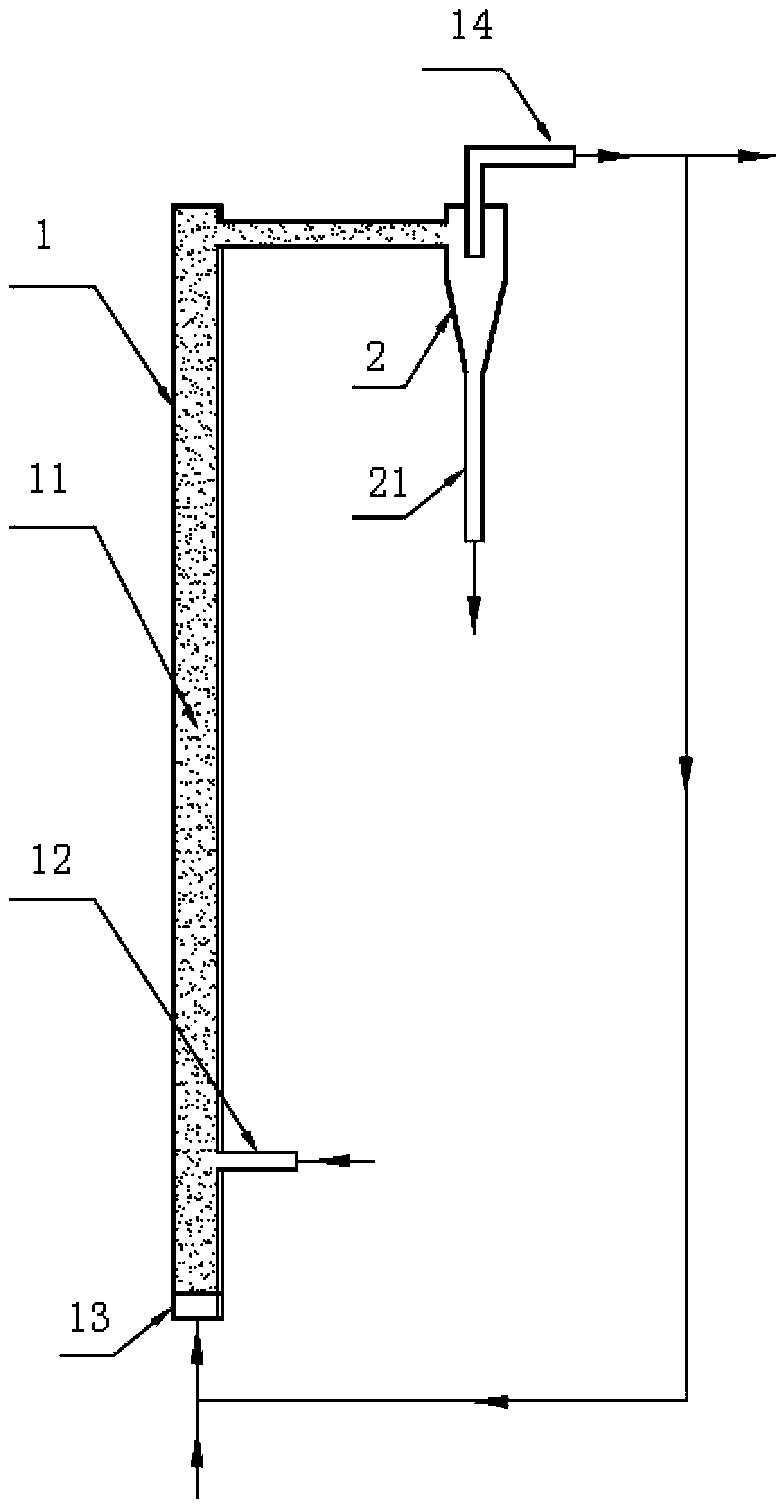

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] as attached figure 1 As shown, a method for suppressing oxygen carrier sintering and reducing heat loss chemical looping combustion is completed according to the following steps. First, the reduced oxygen carrier is sent to the fluidized bed air reactor 1 through the feed pipe 12 Reactive combustion; then extract a part of the oxygen-poor flue gas from the oxygen-poor flue gas outlet 14 at the top of the cyclone separator 2, mix it with the air entering the air inlet 13, and pass it into the fluidized bed air reactor 1 together; The outlet discharges the regenerated oxygen carrier particles;

[0012] Wherein, the chemical looping combustion device for suppressing oxygen carrier sintering and reducing heat loss includes a fluid bed air reactor 1 and a cyclone separator 2; the lower part of the fluid air reactor 1 is connected with a feed pipe 12, and the fluid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com