Thermal power plant flue gas recirculation and sludge drying coupled on-line mixed-burning system

A technology of flue gas recirculation and sludge drying, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. It can solve the problems affecting dust and sulfur discharge and system operation Insufficient flexibility, excessive boiler discharge and other problems, to achieve the effect of reducing the oxygen content of the boiler, flexible system operation mode, and lightening the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

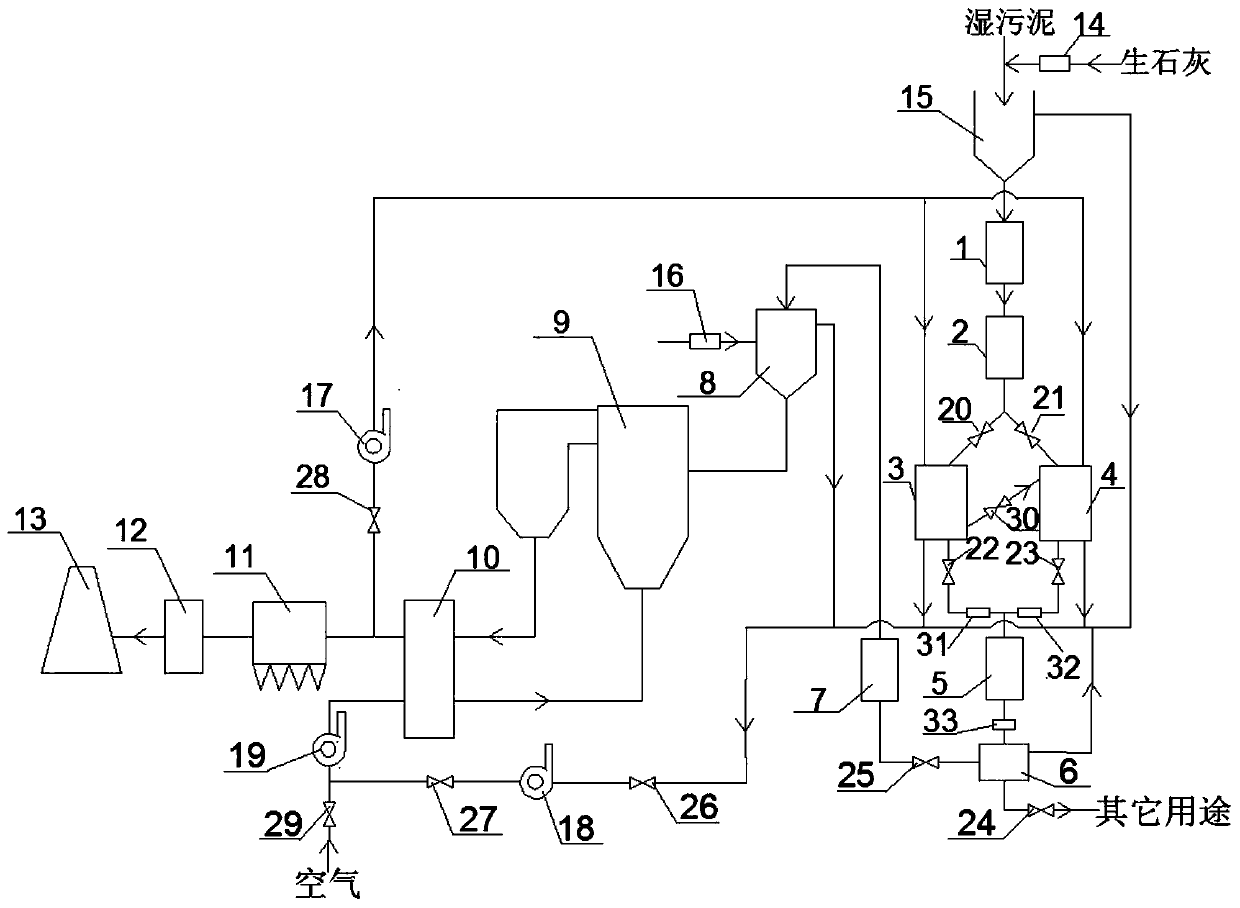

[0025] Such as figure 1As shown, the thermal power plant flue gas recirculation coupling sludge drying online blending system in this embodiment includes a circulating fluidized bed power generation system and a sludge drying system, wherein: the circulating fluidized bed power generation system includes Weighing coal feeder 16, dosing bin 8, boiler 9, air preheater 10, dust collector 11, desulfurization tower 12, chimney 13 and third fan 19, weighing coal feeder 16, dosing bin 8, boiler 9 , air preheater 10, deduster 11, desulfurization tower 12 and chimney 13 are connected successively by pipeline, the inlet of the 3rd fan 19 is connected with air source, the outlet of the 3rd fan 19 is connected with the air side inlet of air preheater 10; The sludge drying system includes a quicklime weighing conveyor 14, a wet sludge bin 15, a first screw convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com