Combined cycle thermoelectric conversion system utilizing multi-grade waste heat of internal combustion engine

A combined cycle, thermoelectric conversion technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as inability to adapt to wide applications, increased irreversible losses, and large installations, and achieve the effect of improving fuel economy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

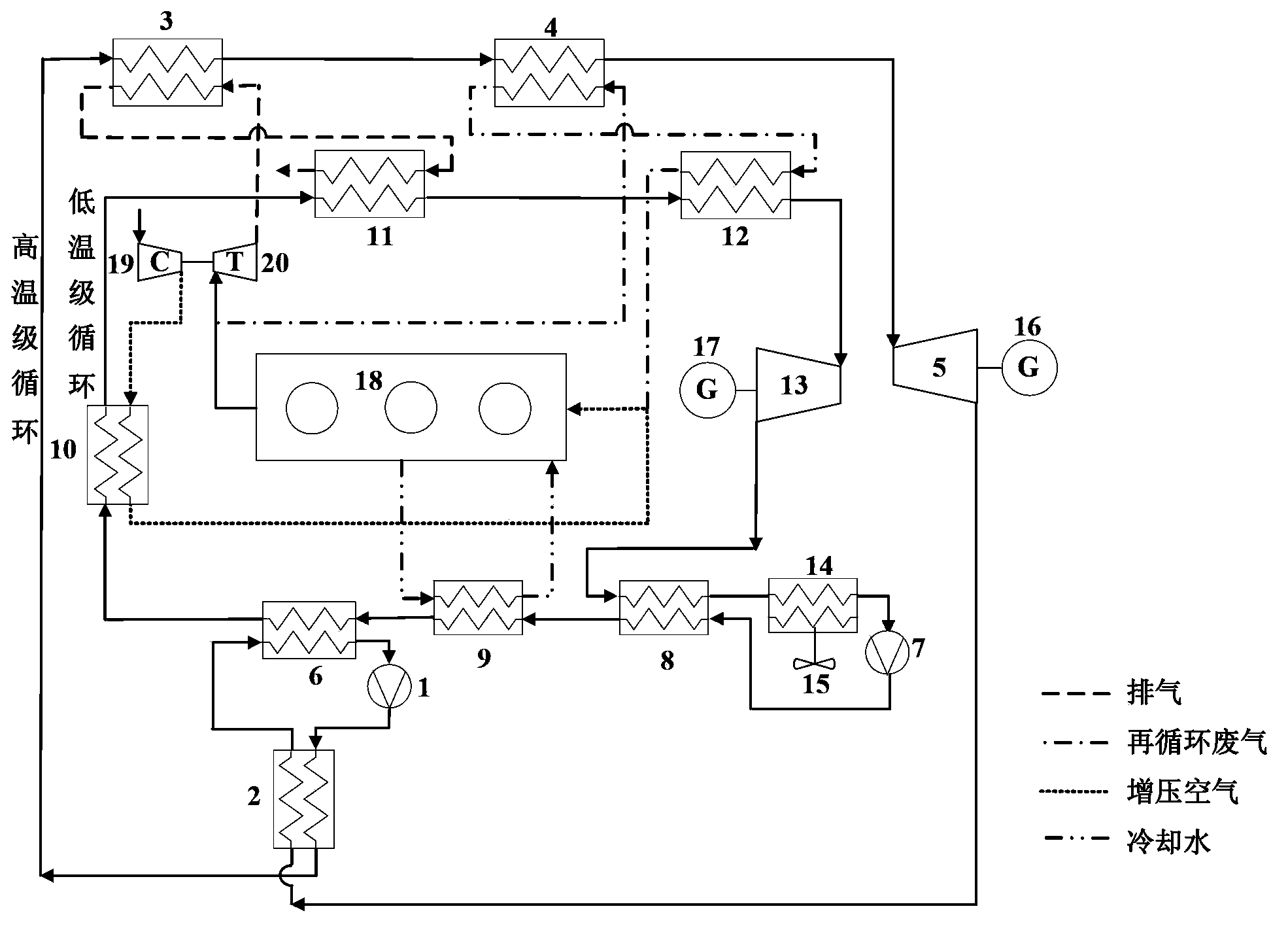

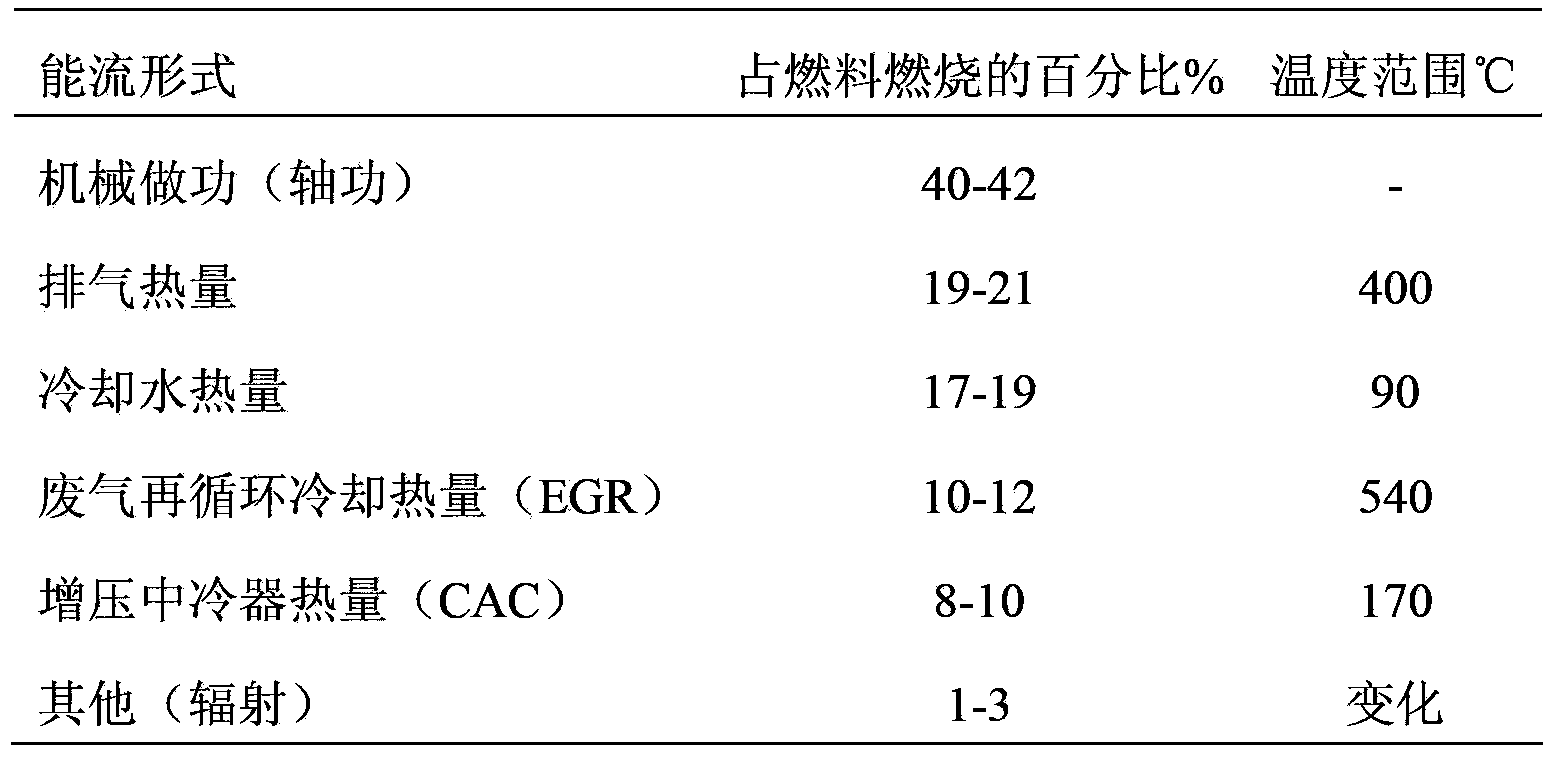

[0024] As shown in the drawings, this embodiment discloses a combined cycle thermoelectric conversion system for utilizing multi-grade waste heat of internal combustion engines. The system is mainly composed of a high-temperature stage cycle and a low-temperature stage cycle. : Exhaust, charge air, recirculated exhaust gas and cooling water provide heat to the combined organic rankine cycle, and cold air provides cooling to the combined cycle. The main components of this system are: high-temperature working medium pump 1, high-temperature regenerator 2, high-temperature exhaust heater 3, high-temperature EGR heater 4, high-temperature expander 5, high-temperature condenser 6, low-temperature Working medium pump 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com