Half-funnel-type nozzle double-layer water channel diamond-impregnated bit

A diamond-impregnated, funnel-type technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of high labor intensity, short service life, and increase the force of the drill bit, so as to reduce the labor intensity of workers and reduce labor costs. The effect of drilling times and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

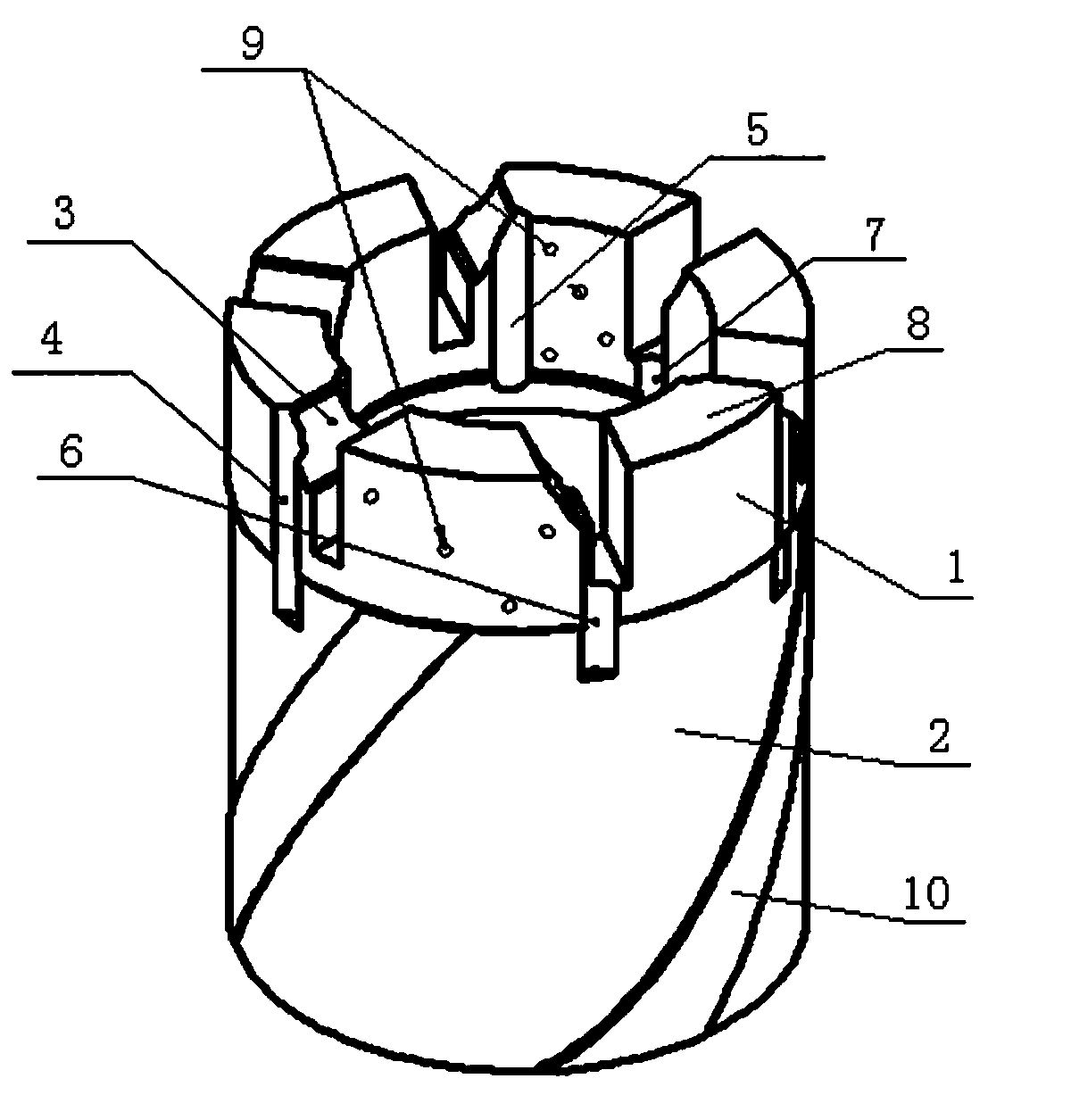

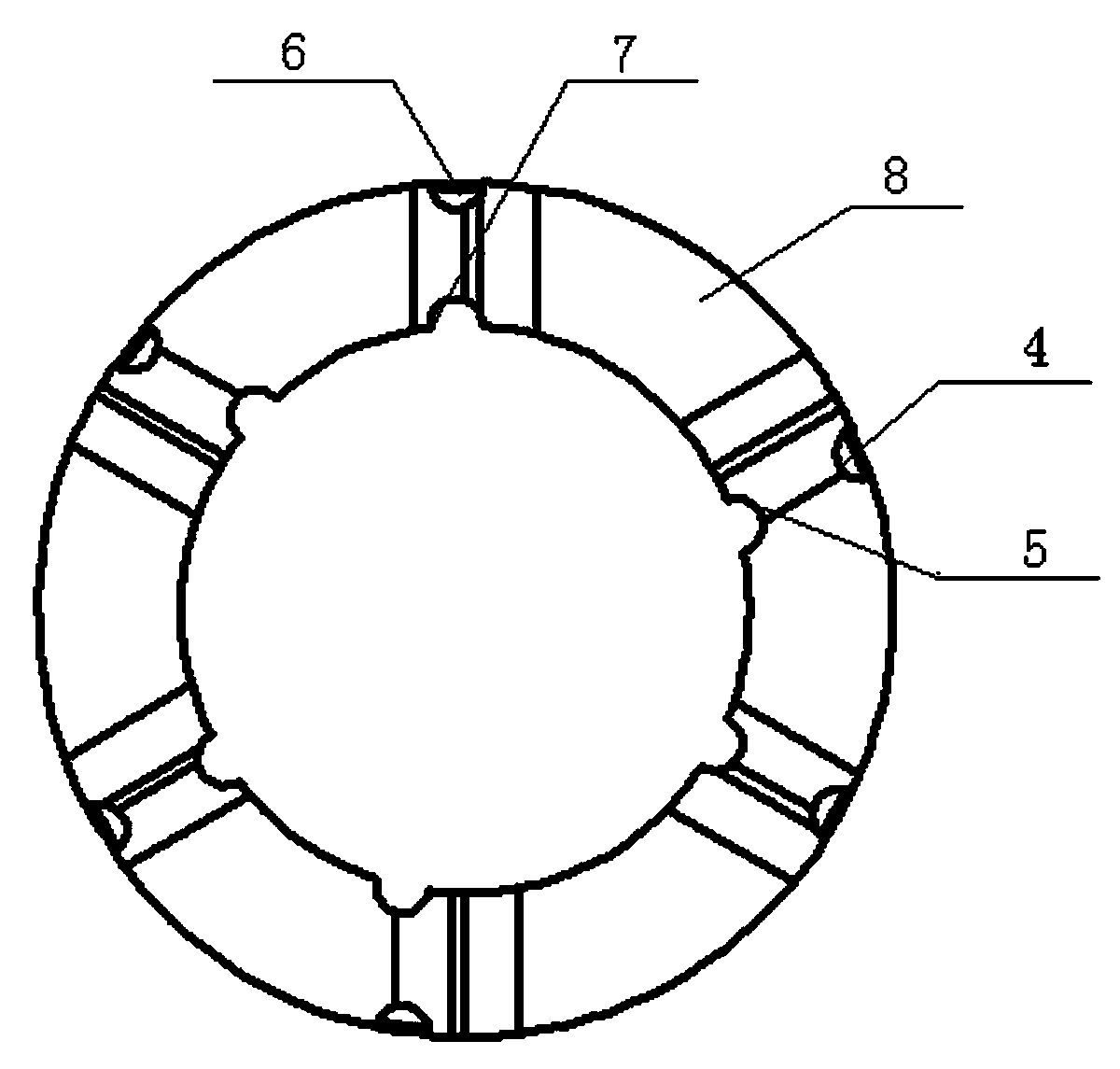

[0020] refer to figure 1 , this embodiment includes a working layer 1 with six wings and a steel body 2, and also includes a stepped water tank and a half-funnel nozzle 3. Below the funnel-shaped nozzle 3, the stepped water tank is located on the inner surface and the outer surface of the working layer 1.

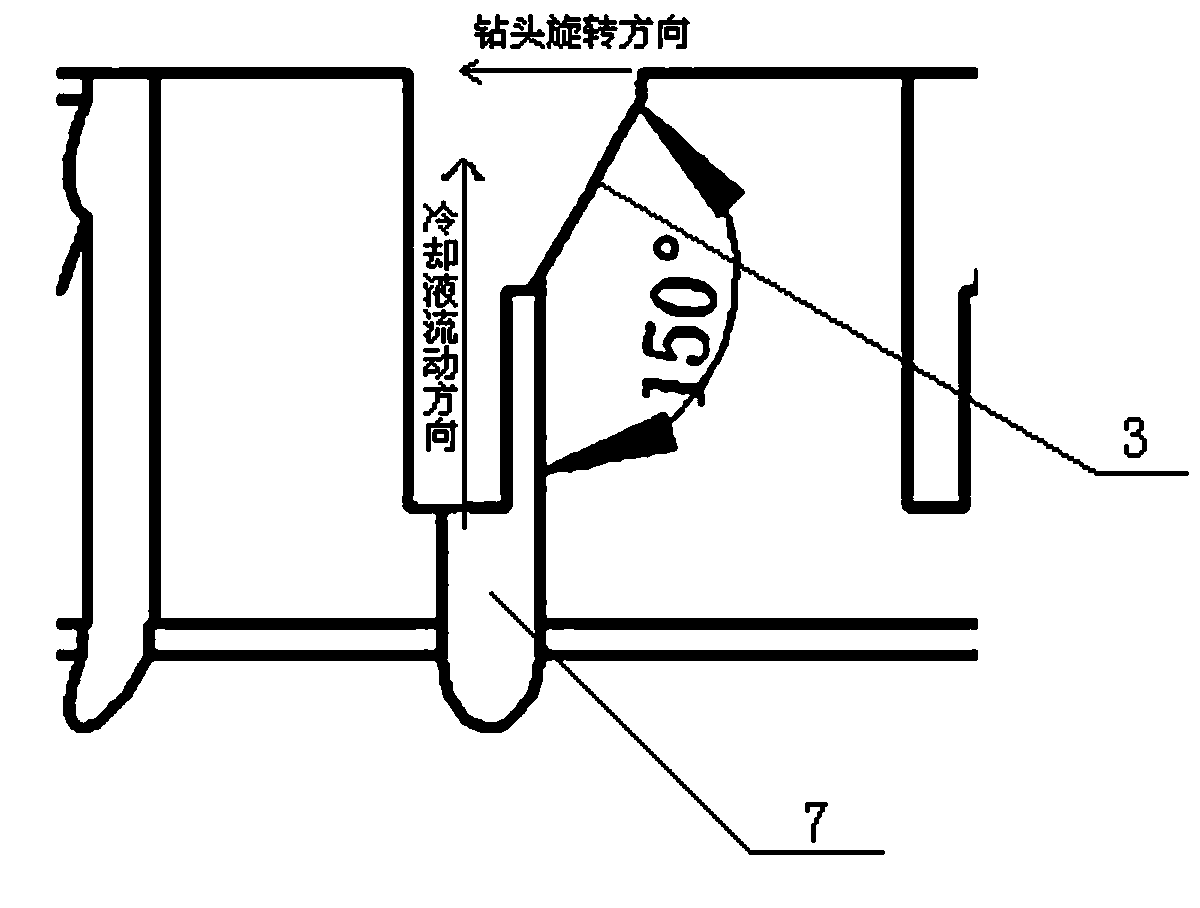

[0021] refer to figure 2 , the inclined surface of the semi-funnel nozzle 3 is set at an angle of 150 degrees to the vertical direction, so as to reduce the cooling water resistance, improve the cooling effect, improve the stress situation, increase the strength of the working layer, and prolong the service life of the drill bit.

[0022] Using the half-funnel nozzle, the coolant can better cool the bottom lip surface of the working layer, and the upper part of the half-funnel nozzle is used as the first layer nozzle to cool the bottom lip surface of the working layer; when the working layer of the drill bit is worn To a certain extent, the lower part of the semi-funnel-...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the stepped water tank is a three-stage water tank, and the inclined surface of the half-funnel-shaped nozzle 3 is set at an angle of 130 degrees to the vertical direction. All the other are with embodiment 1.

Embodiment 3

[0031] The difference between this embodiment and Embodiment 1 is that: the inclined surface of the half-funnel nozzle 3 is set at an angle of 160 degrees to the vertical direction. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com