Pad pasting tearing-off device and method

A technology of film sticking and transmission device, which is applied in the field of thin glass polarizer film sticking and tearing off device, which can solve the problems of no substrate and difficult fixation, and achieve the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The technical solutions of the present invention will be further described in more detail in conjunction with the accompanying drawings and specific embodiments.

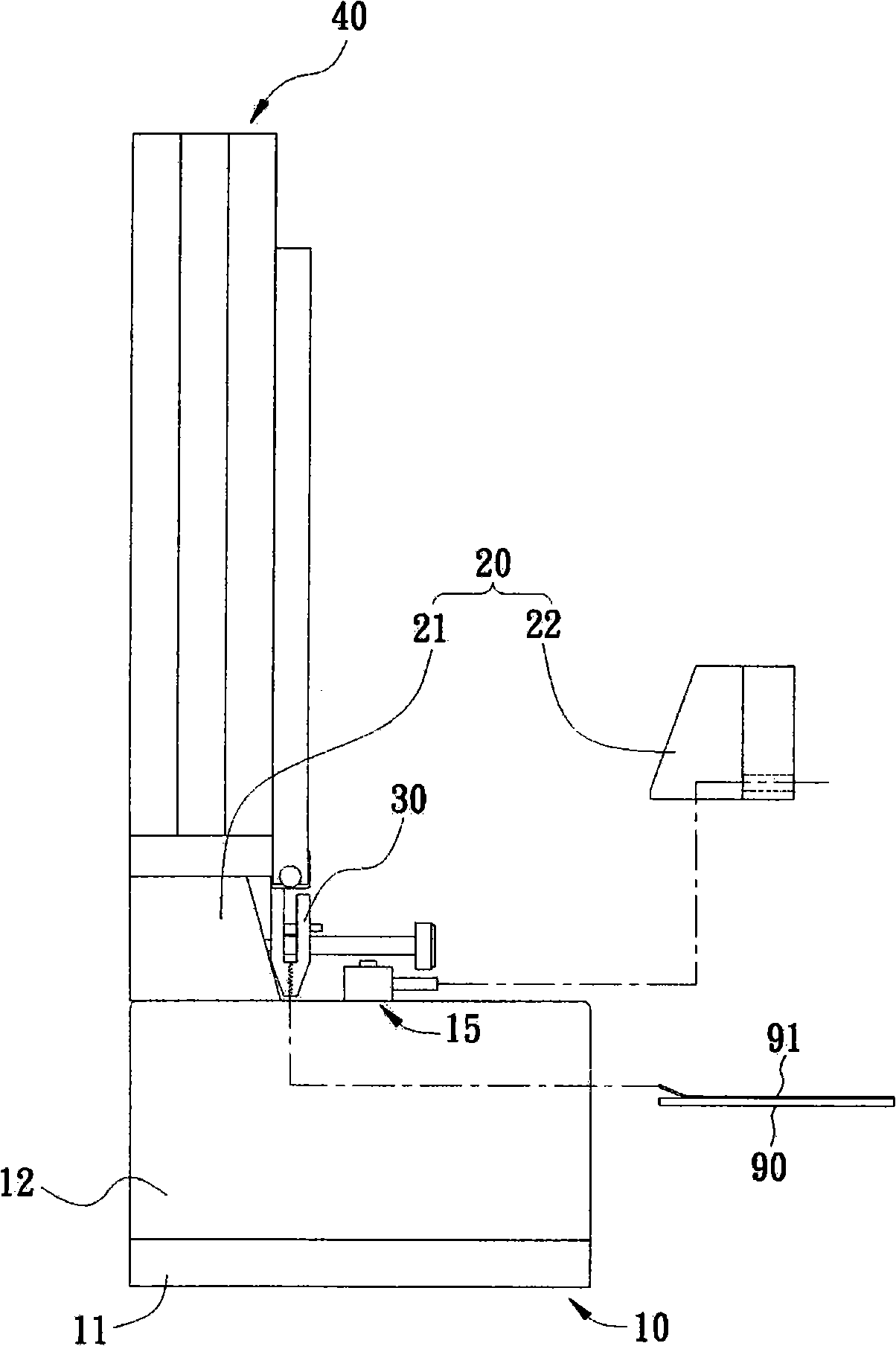

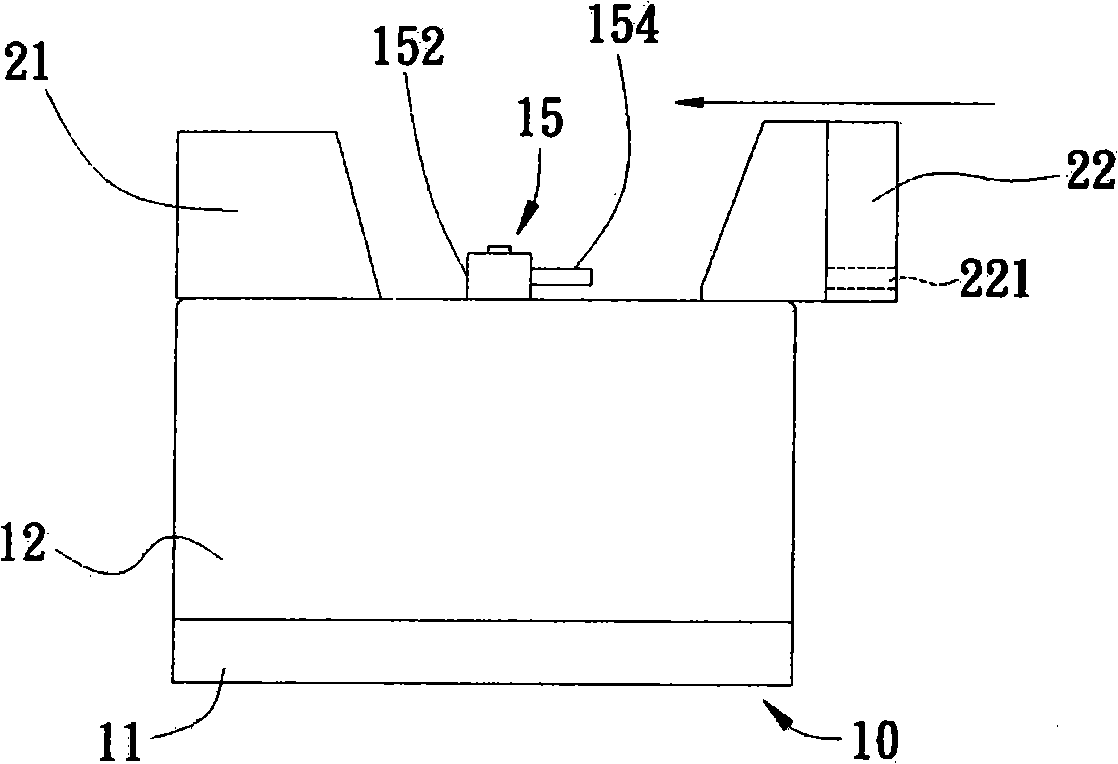

[0067] Please refer to figure 1 and figure 2 As shown, the film peeling device provided by the first embodiment of the present invention is used to peel off the film 91 from the substrate 90 , wherein the film peeling device includes a base 10 , a fixing member 20 , a clamp 30 , and a transmission device 40 . The substrate 90 may be a glass substrate including a polarizer, and the outer surface of the polarizer is covered with a film 91 for release. The polarizer is pasted on the substrate 90 together with the film 91 , so the film 91 must be torn off before the optical properties of the polarizer can be exerted.

[0068] refer to figure 1 and figure 2 As shown, the base 10 includes a bottom plate 11 and two side walls 12 , the two side walls 12 are disposed on the bottom plate 11 parallel to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com