Connection structure of steel bars of prefabricated parapet

A technology for connecting structures and parapet walls, applied in building structures, snow traps, buildings, etc., can solve the problems of not fully reflecting the advantages of industrialization, difficult hoisting, and long construction periods, and achieves simplified prefabrication procedures, shortened construction period, The effect of increasing grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

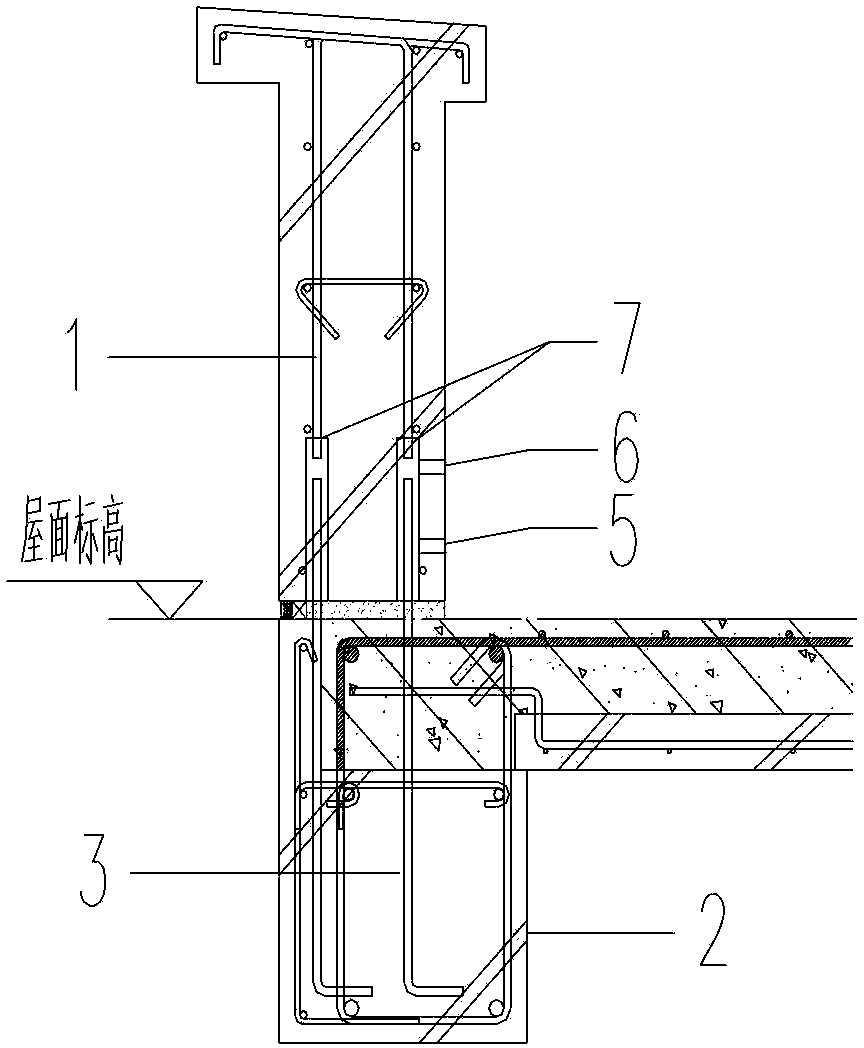

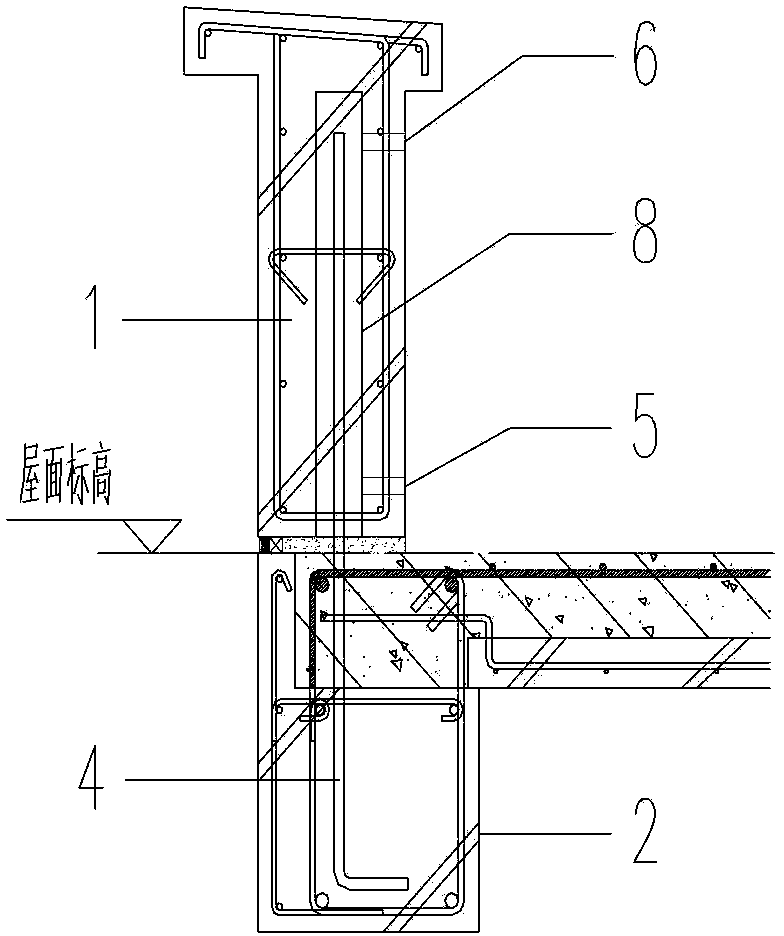

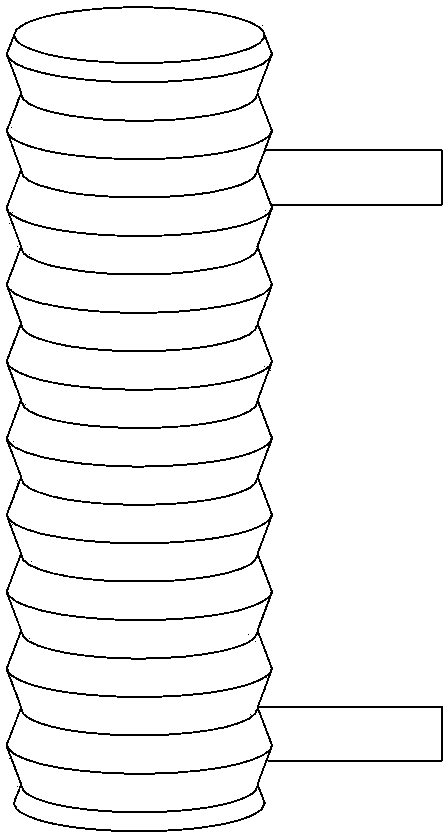

[0016] On the premise of ensuring the strength and service requirements of the parapet wall under the corresponding load conditions, the simplified steel connection method can achieve better economic benefits. In the present invention, the double-row steel bar sleeve connection mode in the traditional connection is changed to a single-row steel bar connection, and a single-row galvanized corrugated steel pipe 8 with an inner diameter 40mm larger than the steel bar diameter is pre-embedded in the middle of the prefabricated parapet 1, and the galvanized corrugated steel pipe The upper part shall be welded and closed with thin iron sheets, and the prefabricated composite beams 2 of the roof are pre-embedded steel bars with large spacing and large diameter. When calculating the pre-embedded steel bars, the thickness h of the parapet wall shall be calculated. 0 The distance from the center of the galvanized bellows of the parapet to the edge of the parapet in the bending direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com