Vertical shaft spiral-flow type inner energy dissipater used for discharging ecological flows

A technology of ecological flow and internal energy dissipation, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problem of no internal energy dissipation suitable for small flows, and achieve novel structure, significant engineering benefits, and energy dissipation layout flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

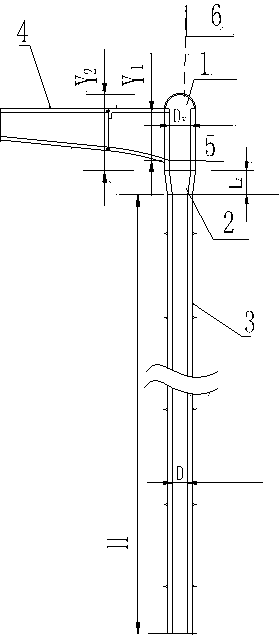

[0040] There is a ventilation hole 6 in the middle of the top of the vortex chamber, the bottom of the vortex chamber is connected to the shaft 3 through the shaft contraction section 2, and the water diversion section 4 at the inlet of the vortex chamber is connected to the side of the vortex chamber 1;

[0041] Determination of the diameter D of the shaft 3:

[0042]

[0043] In the formula:

[0044] D - shaft diameter;

[0045] Q——design flow rate, take 4.4m 3 / s;

[0046] g—gravitational acceleration, take g=9.8 (m / s 2 );

[0047] k——Correction coefficient, take k=1;

[0048] Vortex chamber 1 diameter D v OK for:

[0049] D. v =1.2D;

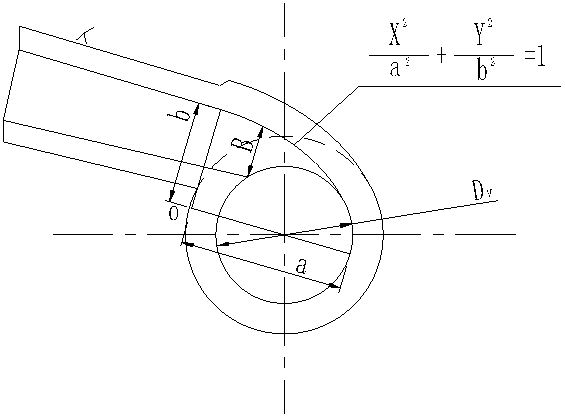

[0050] The inlet water diversion section 4 of the vortex chamber adopts an elliptical contraction type, and the side wall of the vortex chamber and the inlet water diversion section of the vortex chamber is connected by a 1 / 4 elliptic curve, and the major axis of the ellipse is a=1.2D v , minor axis b=0.75 D v ;

[0051] The det...

Embodiment 2

[0064] There is a ventilation hole 6 in the middle of the top of the vortex chamber, the bottom of the vortex chamber is connected to the shaft 3 through the shaft contraction section 2, and the water diversion section 4 at the inlet of the vortex chamber is connected to the side of the vortex chamber 1;

[0065] Determination of the diameter D of the shaft 3:

[0066]

[0067] In the formula:

[0068] D - shaft diameter;

[0069] Q——design flow rate, take 4.4m 3 / s;

[0070] g—gravitational acceleration, take g=9.8 (m / s 2 );

[0071] k——correction coefficient, take k= 1.12;

[0072] Vortex chamber 1 diameter D v OK for:

[0073] D. v =1.3D;

[0074] The inlet water diversion section 4 of the vortex chamber adopts an elliptical contraction type, and the side wall of the vortex chamber and the inlet water diversion section of the vortex chamber is connected by a 1 / 4 elliptic curve, and the major axis of the ellipse is a=1.2D v , minor axis b=0.75 D v ;

[0075] T...

Embodiment 3

[0088] There is a ventilation hole 6 in the middle of the top of the vortex chamber, the bottom of the vortex chamber is connected to the shaft 3 through the shaft contraction section 2, and the water diversion section 4 at the inlet of the vortex chamber is connected to the side of the vortex chamber 1;

[0089] Determination of the diameter D of the shaft 3:

[0090]

[0091] In the formula:

[0092] D - shaft diameter;

[0093] Q——design flow rate, take 4.4m 3 / s;

[0094] g—gravitational acceleration, take g=9.8 (m / s 2 );

[0095] k——correction coefficient, take k=1.25;

[0096] Vortex chamber 1 diameter D v OK for:

[0097] D. v ==1.4D;

[0098] The inlet water diversion section 4 of the vortex chamber adopts an elliptical contraction type, and the side wall of the vortex chamber and the inlet water diversion section of the vortex chamber is connected by a 1 / 4 elliptic curve, and the major axis of the ellipse is a=1.2D v , minor axis b=0.75 D v ;

[0099] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com