Crystallization process of polycrystalline silicon and ingot casting process of polycrystalline silicon

A polycrystalline silicon ingot and polycrystalline silicon technology, which is applied in the field of solar cells, can solve the problems of unstable crystallization speed and poor crystallization stability of liquid silicon, and achieve the effects of stable crystallization speed, improved performance and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

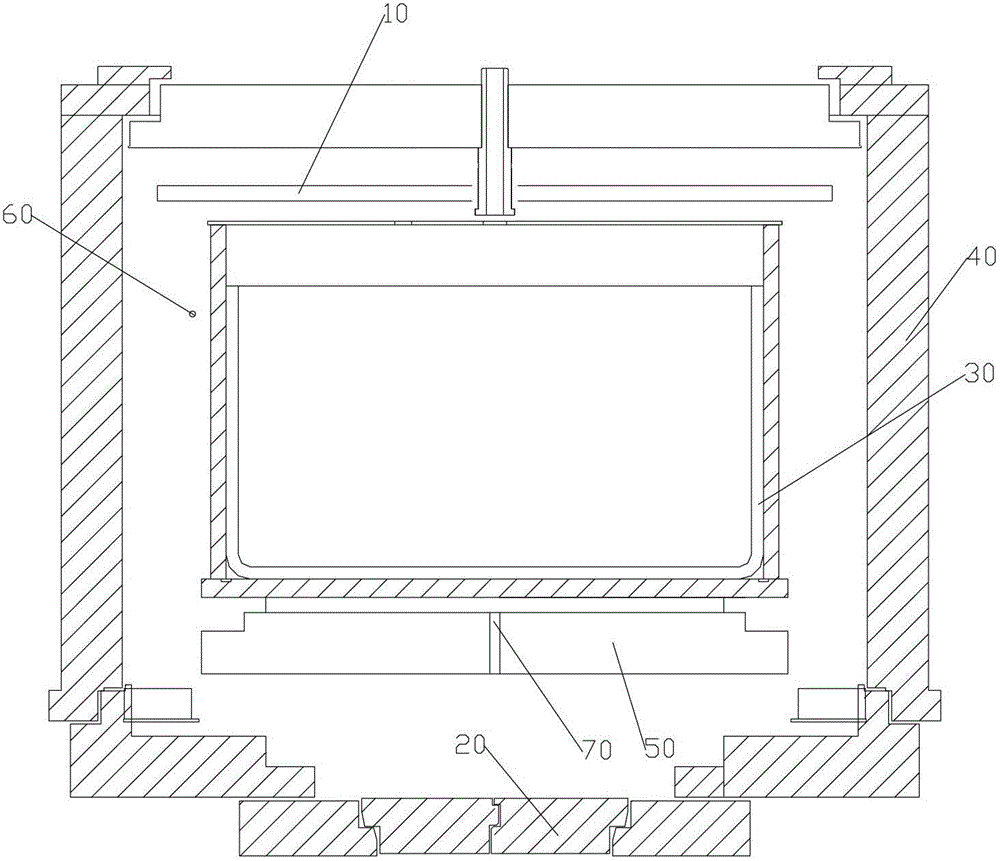

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

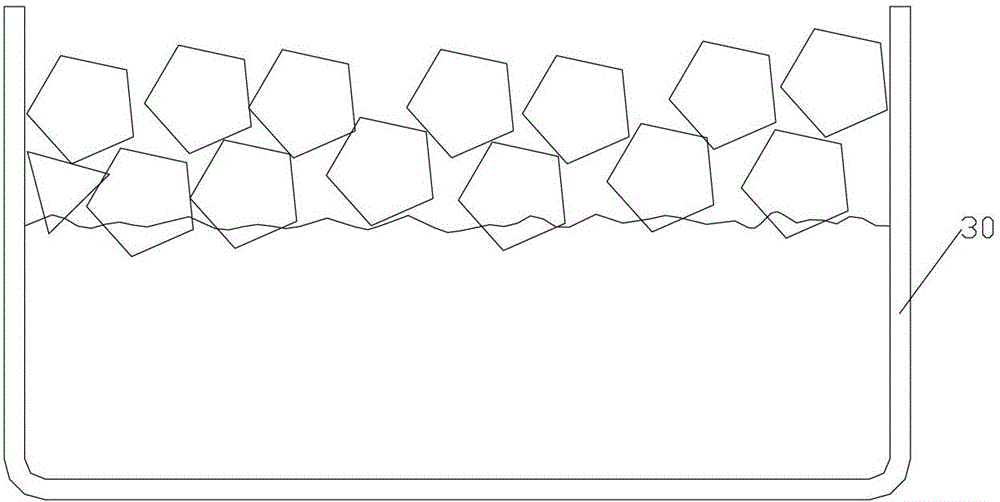

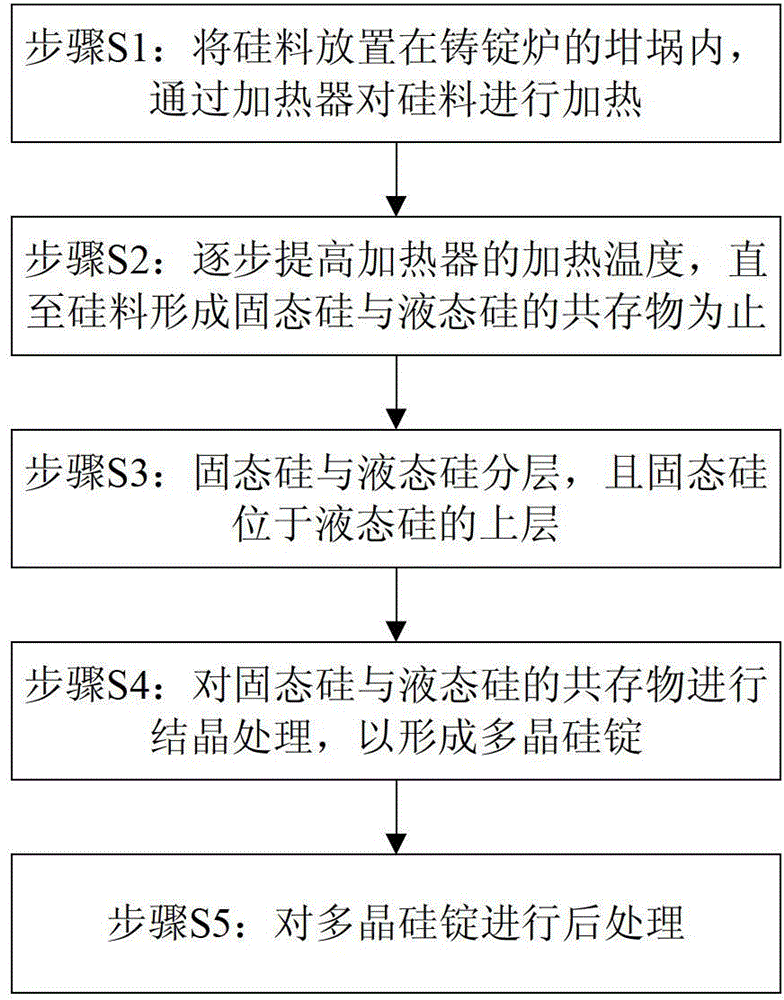

[0024] As a first aspect of the present invention, a polysilicon crystallization process is provided. The crystallization process includes: when the silicon material is in the state of coexistence of solid silicon and liquid silicon, maintain the temperature at the top of the ingot furnace to continue melting the solid silicon, and gradually reduce the temperature at the bottom of the ingot furnace to make the liquid silicon Recrystallization forms polysilicon ingots. The ratio range of solid silicon to liquid silicon is Since the liquid silicon is crystallized when the silicon material is in the state of a solid-liquid mixture, the temperature of the liquid silicon in each ingot furnace is basically the same, and the latent heat contained in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com